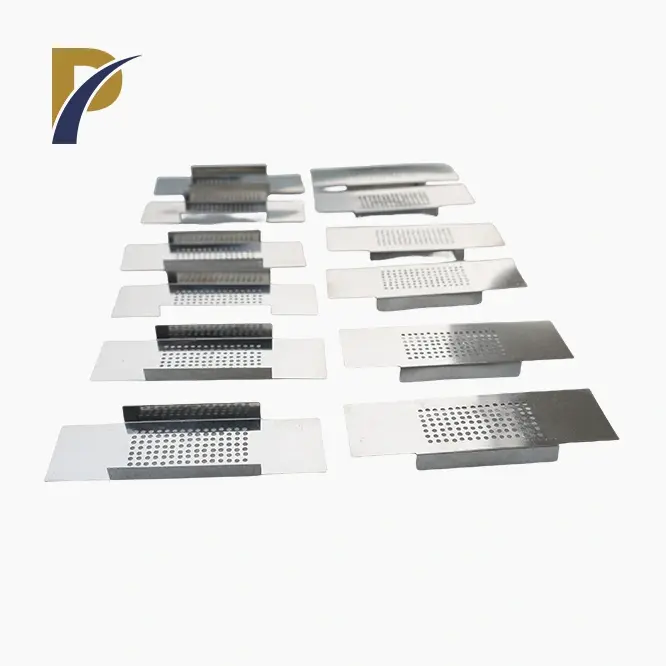

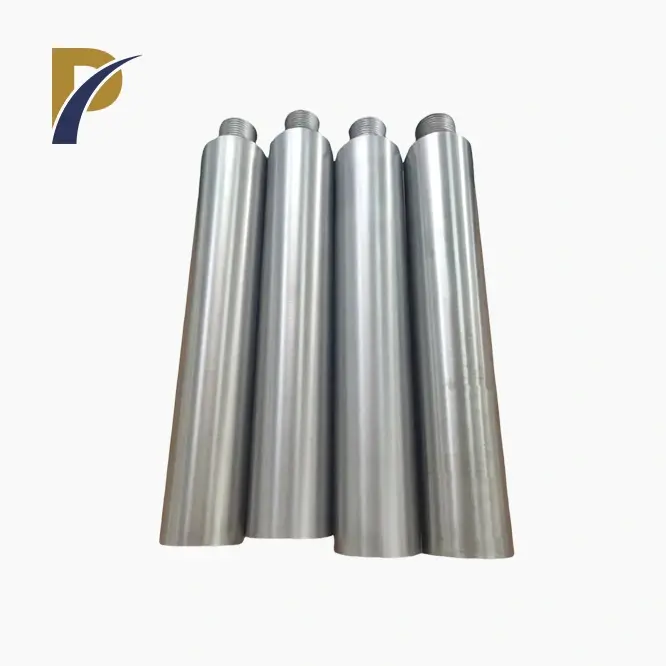

Custom-Made Zirconium Parts

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Custom-Made Zirconium Parts: High-Performance Solutions by Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

At Shaanxi Peakrise Metal Co., Ltd., we specialize in the manufacturing and supply of Custom-Made Zirconium Parts for a variety of industries. Zirconium is a highly valuable material, known for its exceptional resistance to corrosion, making it a perfect solution for applications in chemical processing, nuclear power generation, and aerospace industries. Our custom zirconium parts are engineered to meet the most demanding performance standards, offering unparalleled durability, strength, and thermal stability.

With over a decade of experience in the production of non-ferrous metals, Shaanxi Peakrise Metal Co., Ltd. has become a trusted supplier of high-quality zirconium parts for global clients. We are committed to delivering precision-engineered components that exceed expectations in terms of performance and longevity. Our custom manufacturing process allows us to tailor zirconium parts to meet specific client requirements, ensuring that our products are fully compatible with your project needs.

Shaanxi Peakrise Metal Co., Ltd. operates with a robust focus on innovation and quality control. From material research and development to advanced production processes, we employ cutting-edge technology to ensure the reliability and excellence of our zirconium parts. Our global customer base spans industries in North America, Europe, Asia, and beyond, providing a testament to our high standards and competitive pricing.

|

|

|

|

|

|

|

|

|

Product Specifications

| Parameter | Value | Units |

|---|---|---|

| Zirconium Purity | 99.95% | |

| Density | 6.51 | g/cm³ |

| Melting Point | 1855 | °C |

| Tensile Strength | 330 - 680 | MPa |

| Thermal Conductivity | 22.7 | W/m·K |

| Maximum Working Temperature | 850 | °C |

Chemical and Physical Properties

- Chemical Resistance: Zirconium is highly resistant to corrosion, particularly from acids, alkalis, and seawater, making it suitable for applications in harsh environments.

- Thermal Stability: It maintains strength and performance at high temperatures, making it an ideal choice for high-heat applications such as furnaces and reactors.

- Low Neutron Absorption: Zirconium is used in nuclear reactors due to its low neutron absorption cross-section, ensuring operational safety and efficiency.

- Biocompatibility: Zirconium is biologically inert, making it safe for use in medical devices and implants.

| Grade | Element composition(%)< | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60804 | 97.5 | 0.01 | 0.25~0.37 | 1.2~1.7 | 0.0025 | 0.008 | 0.027 | -- | 0.09~0.16 |

| R60001 | 99.9 | 0.01 | 0.17 | 0.005 | 0.0025 | 0.008 | 0.027 | -- | -- |

Product Functions

-

Corrosion Resistance: The superior corrosion resistance of zirconium makes it indispensable for use in chemical processing plants, where harsh acids and alkalis are present. Zirconium parts prevent corrosion and extend the service life of equipment, reducing maintenance costs.

-

Thermal Performance: Zirconium’s high melting point and thermal stability make it ideal for high-temperature applications. It can withstand extreme conditions without compromising its structural integrity, making it a key material in aerospace and power generation industries.

-

Nuclear Applications: Zirconium’s unique properties, including low neutron absorption, make it a critical material in the nuclear industry. It is used in fuel rod cladding and other nuclear components, ensuring safety and efficiency in power generation.

-

Durability in Challenging Environments: Whether exposed to seawater or aggressive chemicals, zirconium parts offer long-lasting performance, reducing the need for frequent replacements.

Manufacturing Process and Production Flow

-

Raw Material Selection: We source the highest-grade zirconium materials, ensuring that all raw materials meet the required standards for purity and performance.

-

Melting and Casting: The zirconium is melted using advanced vacuum arc melting furnaces to create high-purity ingots. These ingots are then cast into the required shapes for further processing.

-

Machining and Forming: Our advanced CNC machinery allows for precise shaping and machining of zirconium parts to meet the exact specifications provided by our clients.

-

Heat Treatment: To ensure optimal performance, parts undergo heat treatment in a vacuum annealing furnace, enhancing their mechanical properties and thermal stability.

-

Quality Control and Inspection: Each zirconium part undergoes rigorous testing to verify its chemical composition, mechanical properties, and overall quality. Our quality control process ensures that every part meets the highest industry standards.

Packaging

- Wooden Crate Packaging: For large, delicate parts that require maximum protection during transport.

- Carton Packaging: For smaller parts that can be securely packed with cushioning material.

- Foam Padding: Ensures that parts are protected from impact and damage during transit.

- Waterproof and Moisture-Resistant Packaging: Protects products from environmental conditions.

- Customized Packaging: Tailored to meet specific client requirements, ensuring that parts arrive in perfect condition.

- International Standard Packaging: Compliant with global shipping and handling standards.

|

|

|

|

|

|

|

|

|

|

Logistics

- Sea Freight: Cost-effective for bulk shipments across international waters.

- Air Freight: Fast and reliable delivery for urgent orders.

- Land Transport: For deliveries within regions, ensuring timely arrival.

- Multimodal Transport: A combination of different transportation methods to optimize delivery efficiency.

- Courier Services: For smaller, high-value items requiring rapid delivery.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers complete OEM and ODM services for Custom-Made Zirconium Parts. Our expert engineers work closely with clients to develop solutions tailored to their specifications, from material selection to final product design. Whether you need small quantities or large production runs, we are equipped to meet your needs.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

FAQs

-

What is the lead time for custom orders?

Lead times vary depending on the complexity of the part and order size, but typically range from 4-6 weeks. -

Do you provide material certifications?

Yes, we provide full material certifications, including chemical composition and mechanical properties, upon request. -

What industries use zirconium parts?

Zirconium is widely used in the chemical, nuclear, aerospace, and medical industries due to its corrosion resistance and thermal stability. -

Can I request a custom design?

Absolutely. We offer complete customization services to meet the exact specifications of your project. -

How do you ensure the quality of your products?

Every part undergoes rigorous quality control tests to ensure it meets the highest industry standards.

Call to Action: Contact Us

Interested in learning more about our Custom-Made Zirconium Parts? Contact us today at info@peakrisemetal.com to discuss your project needs. Our team of experts is ready to provide you with high-quality zirconium parts tailored to your specifications. Whether you're in aerospace, chemical processing, or nuclear power, Shaanxi Peakrise Metal Co., Ltd. has the solutions you need to succeed.

YOU MAY LIKE

-

VIEW MORE50 diameter molybdenum elecrtode

VIEW MORE50 diameter molybdenum elecrtode -

VIEW MOREmolybdenum riveted boat

VIEW MOREmolybdenum riveted boat -

VIEW MOREmolybdenum crucibles

VIEW MOREmolybdenum crucibles -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREsic heating elements

VIEW MOREsic heating elements -

VIEW MOREmolybdenum wire for wire winding core wire hanger molybdenum lead wire

VIEW MOREmolybdenum wire for wire winding core wire hanger molybdenum lead wire -

VIEW MOREZr 702 cylindrical zirconium crucible

VIEW MOREZr 702 cylindrical zirconium crucible -

VIEW MOREU type sic heater element

VIEW MOREU type sic heater element