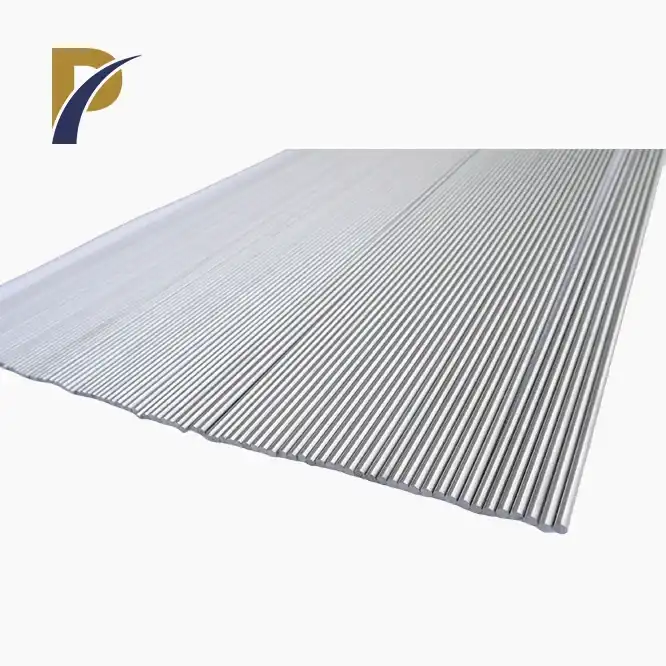

thoriated tungsten rod

Material: Pure Tungsten Or Doped Tungsten

Shape: Tungsten Electrode Rod

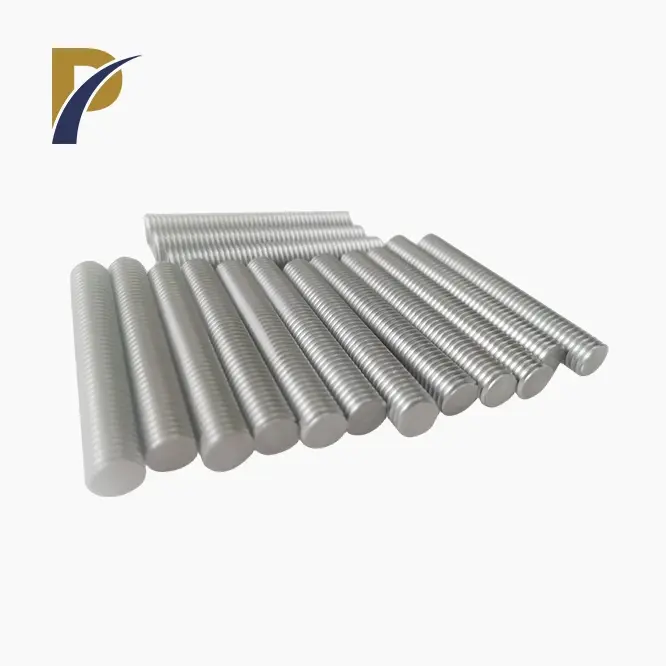

Grade: WT10,WT20,WC20,WL15,WZ3,WZ8,WY20 Etc.

Diameter: 1.0~4.8mm

Length: 150,175,178mm Or As Per Customer

Surface: Polished

Standard: ISO6848,AWS.A5.12 M

MOQ: 10pcs

Application: DC negative electrode welding of carbon steel, stainless steel, nickel and titanium, as well as some special AC welding

PRODUCT DESCRIPTION

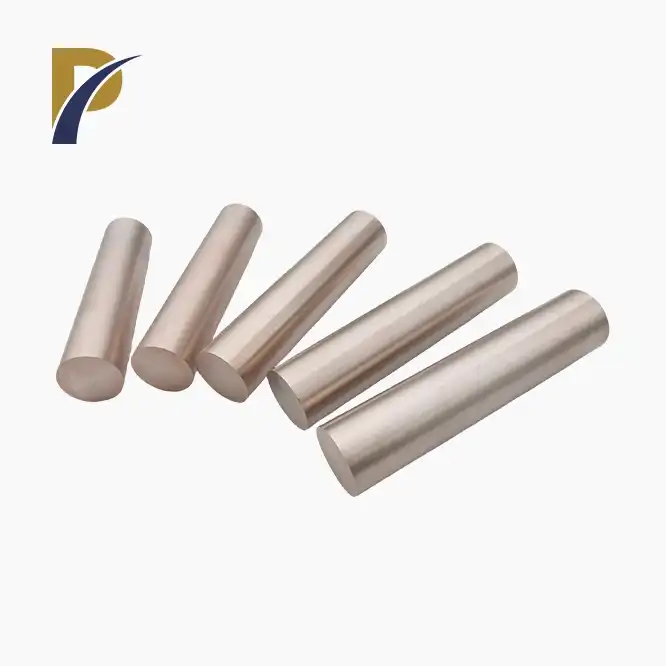

Thoriated Tungsten Rod Introduction

Thoriated tungsten rods are renowned in various industries for their exceptional properties, including high melting points, superior conductivity, and excellent arc starting characteristics. These rods are tungsten electrodes doped with thorium oxide (ThO2), which significantly enhances their performance in demanding applications such as welding and electrical discharge machining (EDM). Shaanxi Peakrise Metal Co., Ltd. stands out as a premier supplier of tungsten rods, offering top-quality products that cater to the exacting standards of global industries.

Product Parameters Table

The following tables present the detailed specifications of our products:

| Parameter | Value |

|---|---|

| Thorium Oxide Content (%) | 1.0 - 2.2 |

| Density (g/cm³) | 19.3 |

| Electrical Conductivity (% IACS) | 28 - 32 |

| Thermal Conductivity (W/m·K) | 173 |

| Melting Point (°C) | 3422 |

| Hardness (HV) | 350 - 400 |

| Dimension | Range |

|---|---|

| Diameter (mm) | 1.0 - 10.0 |

| Length (mm) | 150, 175, 178 |

| Tolerance (mm) | ±0.02 (diameter), ±1.0 (length) |

| Mechanical Properties | Value |

|---|---|

| Tensile Strength (MPa) | 900 - 1100 |

| Yield Strength (MPa) | 800 - 950 |

| Elongation (%) | 10 - 15 |

|

|

Physicochemical Properties

Thoriated tungsten rods offer a unique set of physicochemical properties:

High Melting Point: Excellent performance at high temperatures.

Enhanced Arc Starting: Reliable and easy arc starting.

High Thermal and Electrical Conductivity: Efficient heat and electrical transfer.

Radiation Stability: Stable under radiation environments.

Long Electrode Life: Reduced consumption during usage.

|

|

Thoriated Tungsten Rod Functions

Superior Arc Starting: The thorium content enhances the rod's ability to start arcs quickly and reliably, making it ideal for precision welding tasks.

High Temperature Performance: With a high melting point, these rods perform exceptionally well in high-temperature applications without deforming or melting.

Longer Lifespan: High-Strength Threaded Tungsten Rod have a longer electrode life, reducing the need for frequent replacements and lowering overall operational costs.

Stable Electron Emission: The thorium oxide provides stable electron emission, ensuring consistent performance in electrical discharge applications.

Product Applications

Welding: Used extensively in TIG welding due to their superior arc starting and stability, ensuring high-quality welds.

Electrical Discharge Machining (EDM): Ideal for precision machining of hard metals, providing excellent performance and longevity.

Aerospace: Utilized in the aerospace industry for components that require high thermal resistance and stability.

Power Generation: Employed in power generation equipment where reliable electrical conductivity is crucial.

Nuclear Industry: Used in nuclear applications due to their stability under radiation and high temperature conditions.

|

|

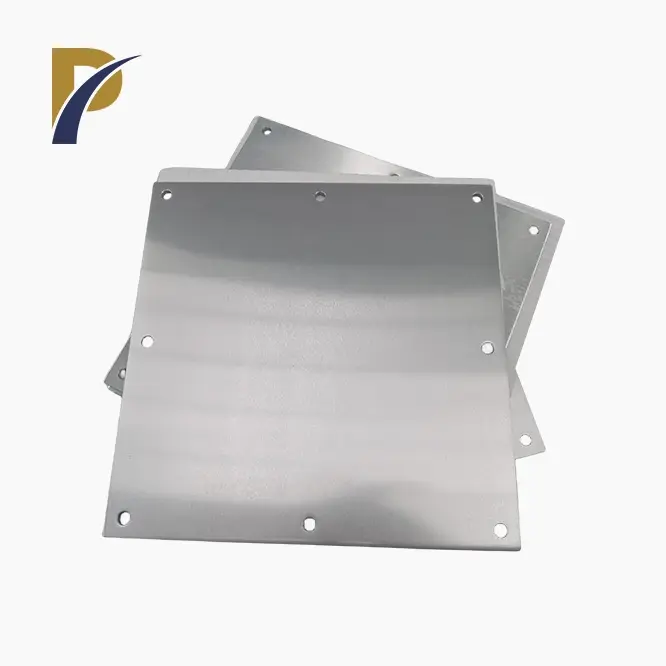

Product Process and Production Flow

Material Selection: Sourcing of high-purity tungsten and thorium oxide.

Powder Mixing: Precise mixing of tungsten and thorium oxide powders.

Pressing: Compaction of the mixed powders into rod forms under high pressure.

Sintering: High-temperature sintering to enhance density and properties.

Machining: Precision machining to meet exact dimensions and tolerances.

Quality Control: Comprehensive inspection and testing to ensure product quality.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility equipped with advanced machinery and technology. Our production capabilities include intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, and more. These facilities enable us to produce high-quality Threaded Tungsten Rod that meet the rigorous demands of our global clientele.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging:

Wooden Boxes: Secure and robust packaging for safe transport.

Cardboard Boxes: Lightweight and cost-effective solutions.

Foam Padding: Added protection to prevent damage during transit.

Waterproof Packaging: Ensures protection from moisture and environmental factors.

Customized Packaging: Tailored solutions to meet specific customer requirements.

Logistics:

Sea Freight: Economical for large shipments.

Air Freight: Fast and efficient for urgent deliveries.

Land Transport: Reliable for regional shipments.

Multimodal Transport: Combining various modes for optimal delivery.

Courier Services: Quick and convenient for smaller packages.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Rich Experience: Over a decade of experience in non-ferrous metal production.

Advanced Technology: Utilization of cutting-edge manufacturing processes and equipment.

Custom Solutions: Comprehensive OEM/ODM services to meet specific customer needs.

Global Reach: Established long-term partnerships with clients in multiple countries.

Quality Assurance: Stringent quality control measures to ensure top-notch products.

|

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer extensive OEM and ODM services, allowing our clients to customize products according to their specific requirements. From initial design to final production, we work closely with our customers to deliver tailored solutions that enhance their operational efficiency and performance.

|

|

FAQ

What is the minimum order quantity (MOQ)?

The MOQ varies depending on the product specifications and customer requirements. Please contact us for more details.

Can you provide samples?

Yes, we can provide samples for testing and evaluation. Contact us to learn more.

What is your delivery time?

Delivery times depend on order size and specifications, typically ranging from 2 to 6 weeks.

Do you offer technical support?

Yes, we provide comprehensive technical support and assistance to ensure optimal product performance.

How do you ensure product quality?

We adhere to strict quality control procedures and conduct thorough inspections at every stage of production.

Contact us

Ready to enhance your operations with high-quality thoriated tungsten rod? Contact Shaanxi Peakrise Metal Co., Ltd. today! Our team is here to provide you with the best solutions tailored to your needs. Email us at info@peakrisemetal.com or visit our website for more information. Let's work together to achieve excellence in your industry.