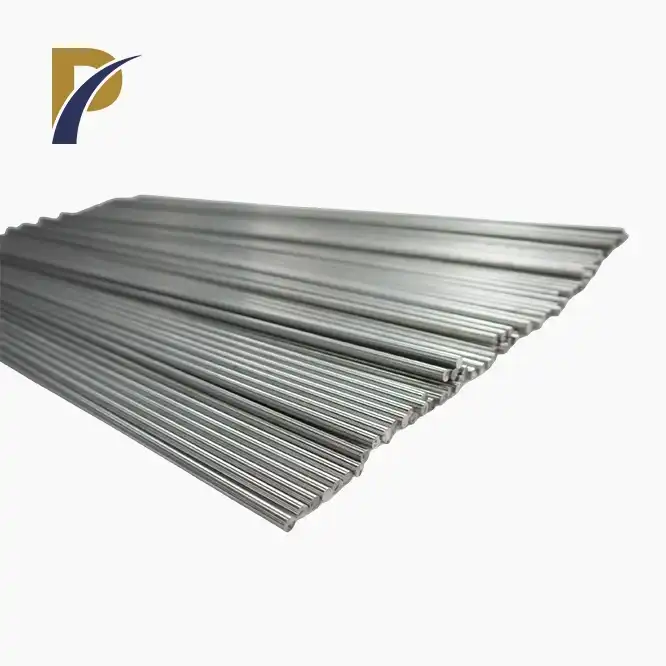

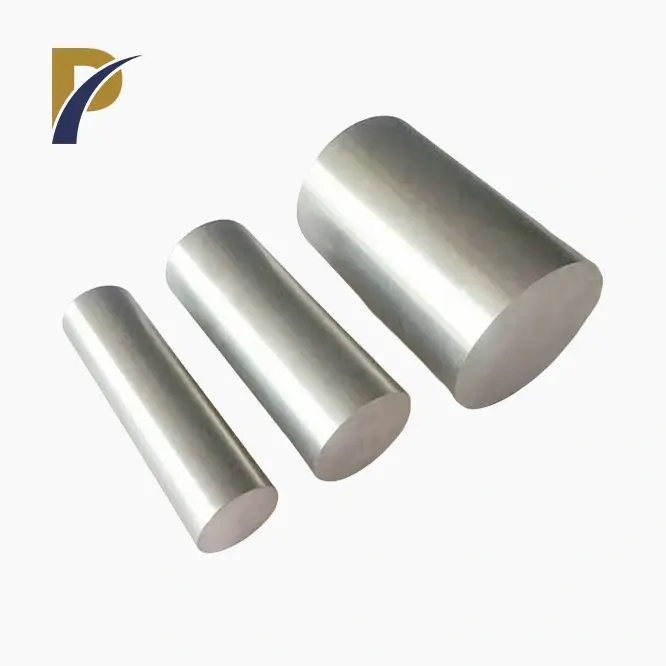

tungsten rods

Length: <2500mm

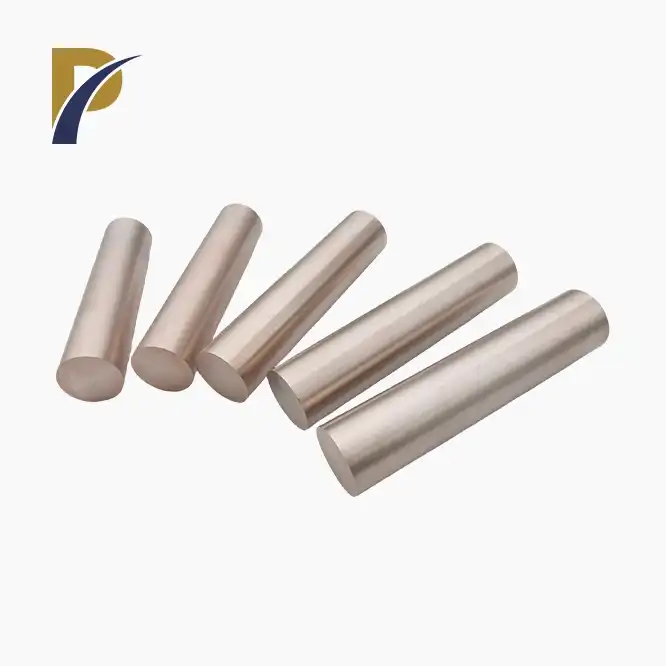

Material: Pure Tungsten

Purity: 99.95%

Density: 19.3 G/cm3

Surface: Polished

Grade: W1,WAL1,WAL2

Melting Point: 3422°C

Tolerance: +/-0.03 mm

Application: Electric light source and electric vacuum parts, used as high temperature heating element and high temperature structural parts.

PRODUCT DESCRIPTION

Tungsten Rods Introduction

Tungsten rods are essential components in various high-performance applications due to their remarkable properties. They are essential in manufacturing, aerospace, electronics, medical, and other fields due to their exceptional hardness, high melting point, and excellent electrical and thermal conductivity. Shaanxi Peakrise Metal Co., Ltd. is a chief provider of great items, offering many details to meet the different necessities of our worldwide customers.

Product Parameters

| Property | Value |

|---|---|

| Tungsten Content (%) | ≥ 99.95 |

| Density (g/cm³) | 19.3 |

| Melting Point (°C) | 3,422 |

| Tensile Strength (MPa) | 700-1,000 |

| Hardness (HV) | 350-500 |

| Electrical Resistivity (μΩ·cm) | 5.5-5.8 |

| Thermal Conductivity (W/m·K) | 170-180 |

| Coefficient of Thermal Expansion (10^-6/°C) | 4.5 |

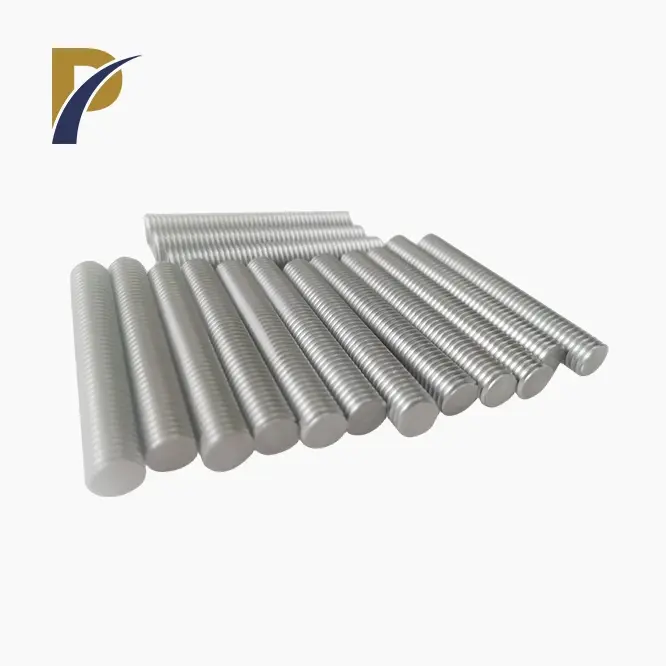

| Diameter (mm) | Length (mm) | Tolerance (mm) |

|---|---|---|

| 2 | 500 | ±0.02 |

| 5 | 1000 | ±0.05 |

| 10 | 2000 | ±0.1 |

| Mechanical Property | Value |

|---|---|

| Elastic Modulus (GPa) | 410 |

| Poisson's Ratio | 0.28 |

| Specific Heat (J/kg·K) | 134 |

|

|

Physical and Chemical Properties

Tungsten rods are characterized by the following properties:

High Melting Point: One of the highest among all elements, making it suitable for high-temperature applications.

Exceptional Hardness: Provides excellent wear resistance and durability.

High Density: Ensures significant mass in compact forms, ideal for various industrial applications.

Thermal and Electrical Conductivity: Excellent conductors of heat and electricity, making them ideal for electronic applications.

Corrosion Resistance: Resists oxidation and corrosion, ensuring long-term performance in challenging environments.

|

|

Tungsten Rods Functions

High Temperature Resistance:

Tungsten rods are suitable for use in environments with extreme heat, such as in aerospace and manufacturing industries.

Exceptional Hardness and Strength:

Ensures durability and long life in applications that experience high wear and mechanical stress.

High Density:

Provides significant mass for applications requiring balance and stability, such as in counterweights.

Excellent Thermal and Electrical Conductivity:

Ideal for use in electronic components and heat sinks due to the Tungsten TIG Rod's ability to efficiently transfer heat and electricity.

Corrosion Resistance:

Enhances longevity and reliability in harsh chemical environments.

Product Applications

Aerospace Industry:

Used in high-temperature components such as rocket nozzles and heat shields due to its high melting point and strength.

Electronics Industry:

Ideal for electrical contacts, filaments, and heat sinks because of its excellent electrical and thermal conductivity.

Medical Field:

Utilized in radiation shielding and medical imaging equipment due to its density and radiation absorption capabilities.

Industrial Manufacturing:

Employed in machining tools and wear-resistant parts because of their hardness and durability.

Defense Applications:

Used in the manufacture of kinetic energy penetrators and armor-piercing projectiles due to its density and strength.

|

|

Manufacturing Process

Powder Metallurgy:

High-purity tungsten powder is pressed into a compact form and then sintered at high temperatures to create a solid rod.

Hot Rolling:

The sintered rods are hot-rolled to refine the grain structure and improve mechanical properties.

Precision Machining:

The rods are then machined to exact dimensions and tolerances, ensuring they meet stringent specifications.

Quality Control:

Each rod undergoes rigorous inspection and testing to ensure it meets the highest quality standards before shipment.

|

|

|

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is a well-known manufacturer of non-ferrous metals that focuses on making nickel alloys, titanium, zirconium, tungsten, molybdenum, tantalum, niobium, and molybdenum alloys. Our broad item range incorporates north of 100 unique things, custom fitted to meet the particular necessities of our clients around the world. We've been focusing on exporting high-quality non-ferrous metal products since 2010 and have built strong relationships with customers in Taiwan, Ukraine, South Korea, the US, Australia, Germany, Iran, and other nations. Our commitment to quality and consumer loyalty has gained notoriety for greatness in the business.

Intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, vacuum annealing furnaces, rolling mills, wire drawing machines, plasma welding rooms, lathes, milling machines, sawing machines, drilling machines, shears, stamping equipment, cutting equipment, grinders, straightening machines, CNC machines, and a variety of other equipment are among the cutting-edge features of our cutting-edge production facilities. We are able to consistently provide our customers with high-quality goods and services thanks to this cutting-edge equipment.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

Packaging Options:

- Wooden crate packaging

- Carton packaging

- Foam-filled packaging

- Waterproof and moisture-proof packaging

- Custom packaging

- International standard packaging

Logistics Options:

- Sea freight

- Air freight

- Land transport

- Multimodal transport

- Express delivery services

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Extensive Experience:

Over a decade of expertise in the production and supply of non-ferrous metals.

High-Quality Products:

Commitment to delivering products that meet the highest quality standards.

Advanced Technology:

State-of-the-art manufacturing facilities and equipment.

Global Reach:

Established export network and long-term relationships with international clients.

Customer-Centric Approach:

Focus on customer satisfaction and tailored solutions to meet specific needs.

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services, providing customized solutions to meet the unique requirements of our clients. Our team of experts works closely with customers to design and manufacture products that align with their specifications, ensuring high-quality and reliable performance.

|

|

FAQ

What is the typical composition of the rods?

High-Purity Tungsten TIG Rod typically consists of ≥ 99.95% pure tungsten.

What are the primary applications of products?

Common applications include aerospace components, electronic contacts, medical radiation shielding, industrial machining tools, and defense products.

How does tungsten perform in high-temperature environments?

Tungsten has one of the highest melting points among all elements, making it ideal for high-temperature applications.

Can you provide custom sizes and shapes for the products?

Yes, we offer OEM/ODM services and can customize products to meet specific client requirements.

What are the shipping options for international orders?

We offer various logistics options, including sea freight, air freight, land transport, multimodal transport, and express delivery services.

Contact us

We invite global buyers to partner with Shaanxi Peakrise Metal Co., Ltd. for high-quality tungsten rods and other non-ferrous metal products. Our commitment to excellence and customer satisfaction ensures that you receive the best products and services. For more information or to place an order, please contact us at info@peakrisemetal.com. We look forward to working with you and meeting your needs with our top-tier products and solutions.