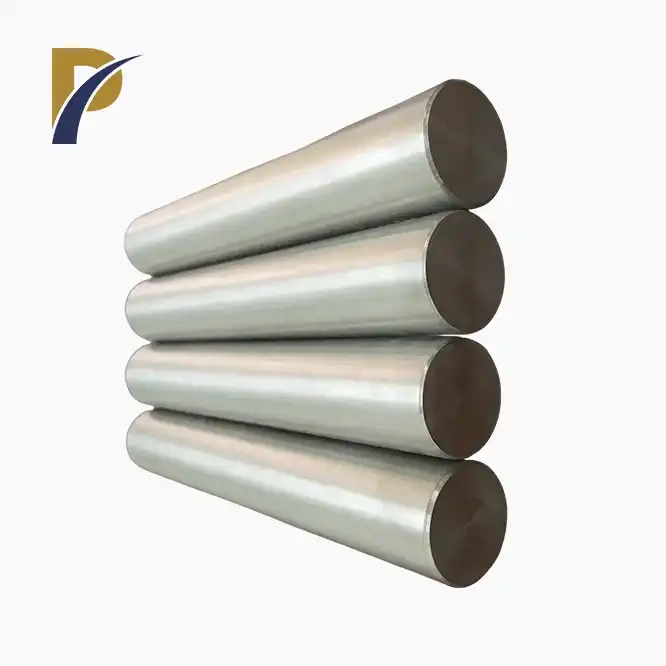

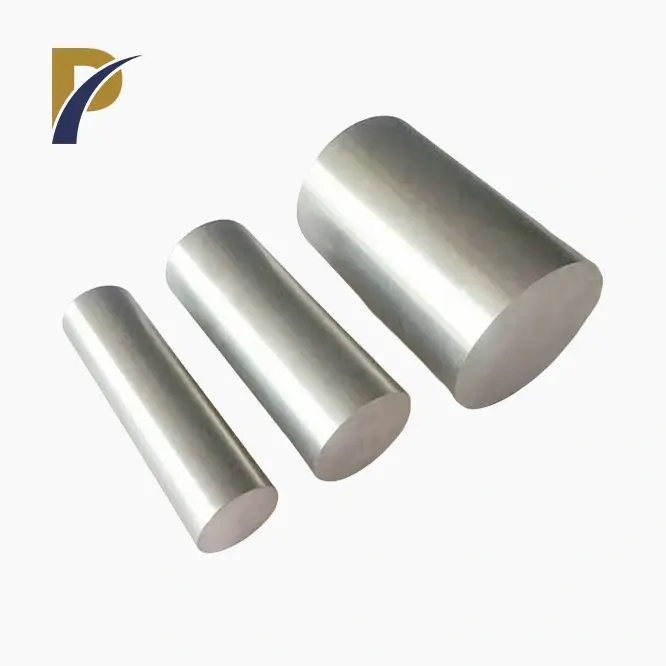

tantalum alloy rod

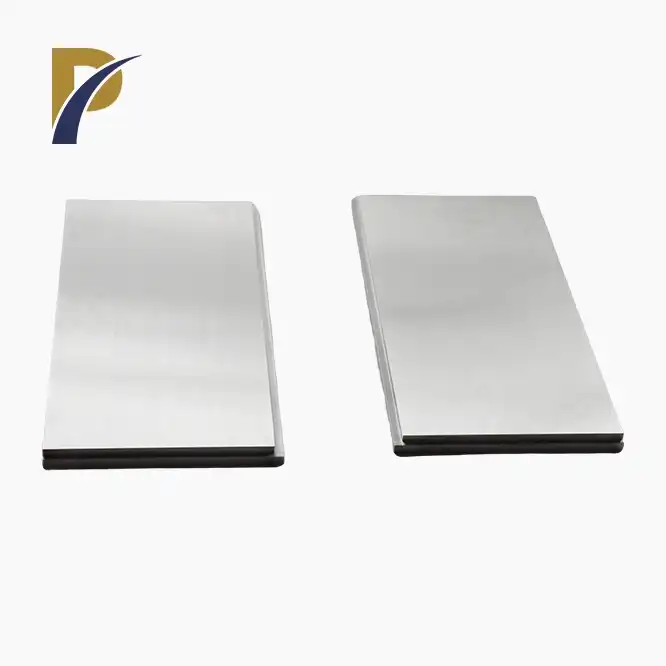

Material: Tantalum & Tantalum Alloy

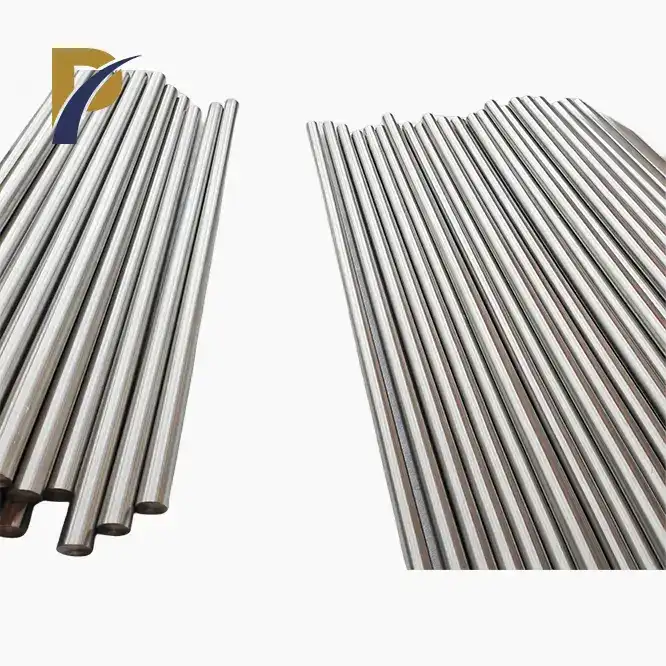

Size: ¢3~¢120mm

Melting Point: 2980℃

Shape: Rod/Bar

Grade:Ta1,Ta2,RO5200,RO5400,RO5252,RO5255,TaNb3

Standard: ASTM B365

Surface Treatment: Polishing

PRODUCT DESCRIPTION

Tantalum Alloy Rod Introduction

At Shaanxi Peakrise Metal Co., Ltd, we specialize in producing high-quality tantalum alloy rods designed to meet the demanding requirements of various industrial applications. Our products are renowned for their exceptional properties, including high melting points, excellent corrosion resistance, and superior mechanical strength. These features make them ideal for use in challenging environments where traditional materials might fail.

Product Parameters

Basic Specifications

| Diameter (mm) | Length (mm) | Alloy Composition (%) | Density (g/cm³) |

|---|---|---|---|

| 1.0 | 1000 | Ta-5W | 16.6 |

| 5.0 | 1500 | Ta-10W | 16.7 |

| 10.0 | 2000 | Ta-20W | 16.8 |

Mechanical Properties

| Property | Value (Ta-5W) | Value (Ta-10W) | Value (Ta-20W) |

|---|---|---|---|

| Tensile Strength (MPa) | 350 | 400 | 450 |

| Yield Strength (MPa) | 150 | 200 | 250 |

| Elongation (%) | 10 | 12 | 8 |

Thermal Properties

| Property | Value (Ta-5W) | Value (Ta-10W) | Value (Ta-20W) |

|---|---|---|---|

| Melting Point (°C) | 2996 | 3000 | 3050 |

| Thermal Conductivity (W/m·K) | 54 | 55 | 56 |

| Coefficient of Thermal Expansion (x10⁻⁶/K) | 6.2 | 6.1 | 6.0 |

|

|

Physical and Chemical Properties

Its exhibit exceptional physical and chemical properties, including:

High Melting Point: Tantalum alloys can withstand extremely high temperatures, making them suitable for high-temperature applications.

Corrosion Resistance: Pure tantalum sheet is highly resistant to corrosion by acids and other harsh chemicals, ensuring long-lasting performance.

Ductility: The alloy maintains good ductility even at high temperatures, allowing for various processing and manufacturing techniques.

|

|

Tantalum Alloy Rod Functions

High-Temperature Stability: Ideal for applications involving high temperatures, such as aerospace and defense industries.

Chemical Resistance: Perfect for use in chemical processing equipment due to its resistance to acids and corrosive environments.

Wear Resistance: Excellent choice for components subjected to high wear and tear.

Tantalum Alloy Rod Applications

Aerospace Industry: tantalum alloy rod is used in components for aircraft and spacecraft that must perform reliably under extreme conditions.

Electronics Manufacturing: Employed in the production of high-precision electronic components and devices.

Chemical Processing: Suitable for manufacturing equipment used in handling and processing corrosive chemicals.

|

|

Manufacturing Process

Material Selection: We begin with high-purity tantalum and alloying elements.

Melting and Alloying: Using advanced vacuum arc melting furnaces, we produce the tantalum alloy rod.

Forging and Rolling: The alloy is forged and rolled into rods of various sizes.

Heat Treatment: We conduct heat treatment to enhance the material's properties.

Inspection and Quality Control: Each rod undergoes rigorous testing to ensure compliance with our quality standards.

|

|

|

About Our Factory

Shaanxi Peakrise Metal Co., Ltd is a leading manufacturer of tantalum and other refractory metals. With over a decade of experience, we have developed a comprehensive production process that integrates material research, development, testing, and inventory management. Our factory is equipped with state-of-the-art machinery, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, and precision cutting tools.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

Packaging:

Wooden Crates: For secure and sturdy packaging during transport.

Cardboard Boxes: Used for smaller quantities.

Foam Padding: Ensures protection against shocks and vibrations.

Waterproof Wrapping: Provides additional protection against moisture.

Custom Packaging: Available upon request to meet specific needs.

Logistics:

Sea Freight: Cost-effective for large orders.

Air Freight: Fast delivery for urgent shipments.

Land Transport: Suitable for regional distribution.

Multimodal Transport: Combines different transport methods for efficiency.

Courier Services: For small or urgent deliveries.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Extensive Experience: Over ten years in the non-ferrous metal industry.

Quality Assurance: Rigorous testing and quality control processes.

Comprehensive Production: Advanced equipment and skilled personnel.

Global Reach: High-temperature pure tantalum sheet exported to numerous countries with a strong international presence.

Customer Focus: Tailored solutions and excellent customer service.

|

OEM Services

We offer OEM and ODM services to meet custom requirements. Our team works closely with clients to design and manufacture products that meet specific application needs.

|

|

Frequently Asked Questions

What is the lead time for ordering its?

Typical lead time is 4-6 weeks, depending on the order size and customization.

Can you provide custom sizes for products?

Yes, we offer custom dimensions and alloy compositions.

What are the payment terms?

Payment terms include advance payment or letter of credit.

Do you offer technical support for product selection?

Yes, our technical team provides support to help choose the right product.

What are the shipping options available?

We offer sea, air, land, and courier shipping options.

Contact Us

For more information or to place an order, please reach out to us at Shaanxi Peakrise Metal Co., Ltd. We look forward to collaborating with you to provide the best tantalum alloy rods for your needs.

Email: info@peakrisemetal.com