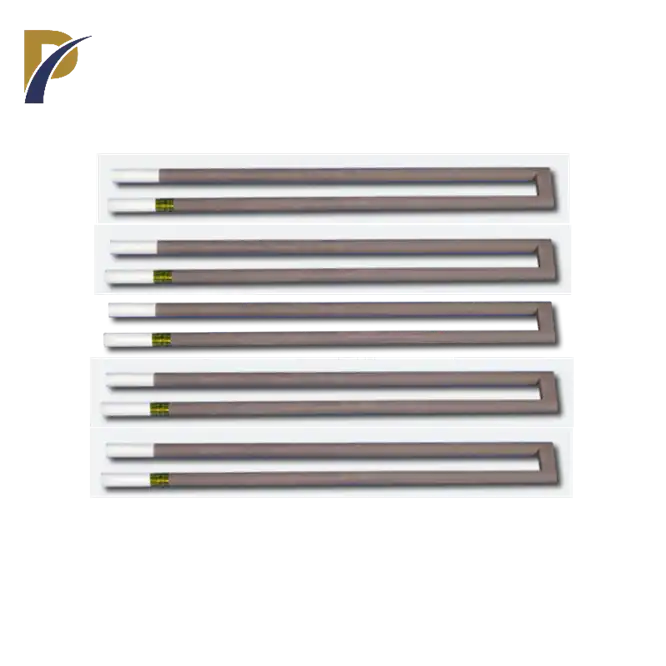

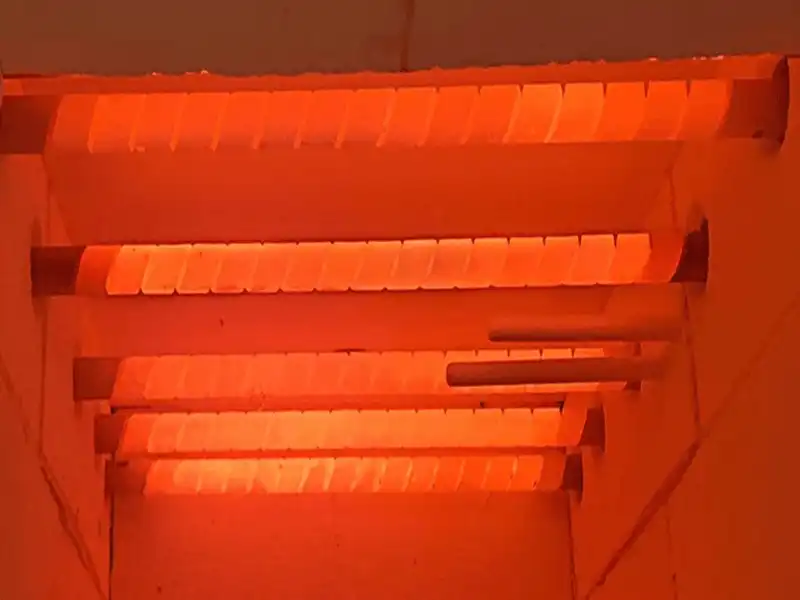

electric furnace sic heating element

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

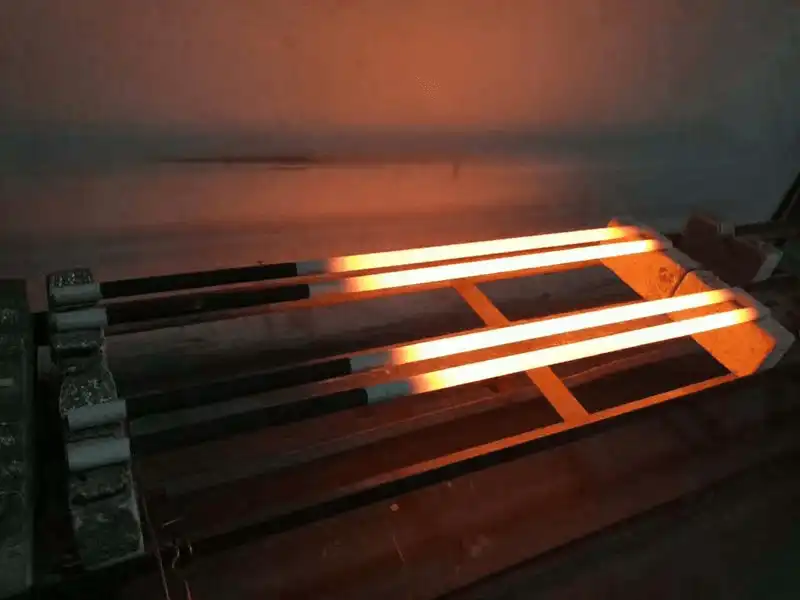

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Electric Furnace Sic Heating Element Introduction

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of electric furnace SiC heating elements. The products are crucial components in electric furnaces due to their high-temperature stability, excellent thermal conductivity, and long service life. These elements are commonly used in various industrial heating applications, such as metal melting, heat treatment, ceramics sintering, and laboratory furnaces.

Our electric furnace sic heating element is designed to deliver outstanding performance, even in the most demanding environments. At Shaanxi Peakrise Metal Co., Ltd., we leverage our extensive experience and advanced manufacturing techniques to produce the products that meet the highest industry standards. Our products are engineered for reliability and efficiency, ensuring consistent heating performance and reduced maintenance costs for our clients.

Product Specifications

| Parameter | Value |

|---|---|

| Maximum Temperature | 1,600°C |

| Density | 2.6 g/cm³ |

| Electrical Resistivity | 0.1-10 Ωcm |

| Parameter | Value |

|---|---|

| Thermal Conductivity | 120 W/m·K |

| Modulus of Rupture | 250 MPa |

| Diameter | 10-60 mm |

| Parameter | Value |

|---|---|

| Length | 300-3000 mm |

| Power Rating | 0.5-50 kW |

| Operating Voltage | 110-480 V |

Physical and Chemical Properties

- High thermal conductivity: Ensures efficient heat transfer and uniform temperature distribution.

- Excellent thermal shock resistance: Can withstand rapid temperature changes without damage.

- High mechanical strength: Durable under extreme conditions and mechanical stress.

- Oxidation resistance: Maintains performance even in oxidizing environments.

- Low thermal expansion coefficient: Minimizes thermal distortion and ensures dimensional stability.

|

|

Electric Furnace Sic Heating Element Features

- High Efficiency: Electric Furnace Sic Heating Elements provide rapid heating with low energy consumption, making them cost-effective.

- Durability: Long service life due to high resistance to oxidation and chemical wear.

- Uniform Heating: Ensures consistent temperature distribution across the heating area.

- Customizable: Available in various sizes and shapes to meet specific application requirements.

- Easy Installation: Simple to integrate into existing furnace systems.

Product Applications

- Metal Melting: Used in furnaces for melting ferrous and non-ferrous metals, providing uniform heating and efficient melting processes.

- Heat Treatment: Ideal for heat-treating processes like annealing, tempering, and hardening of metals, ensuring precise temperature control.

- Ceramic Sintering: Used in the sintering of ceramics, ensuring uniform heat distribution for high-quality ceramic products.

- Laboratory Furnaces: Common in laboratory settings for various high-temperature experiments and processes.

- Glass Processing: Used in the manufacture and processing of glass products, providing consistent and controlled heating.

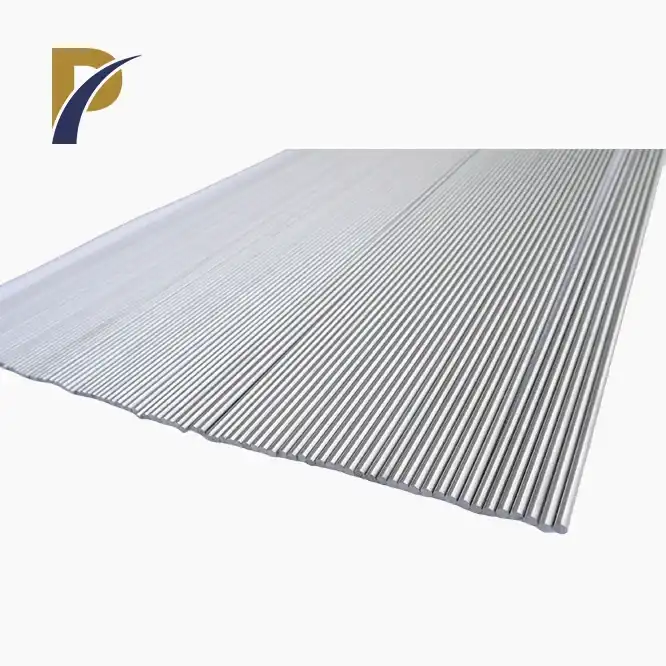

Manufacturing Process

- Raw Material Selection: The products are chosen for their purity and performance.

- Mixing and Molding: Powders are mixed with binders and formed into the desired shapes through molding processes.

- Sintering: The products are sintered at high temperatures to achieve the required mechanical and thermal properties.

- Machining: Sintered elements are machined to precise dimensions and tolerances.

- Quality Control: Each element undergoes rigorous testing to ensure it meets industry standards.

|

|

|

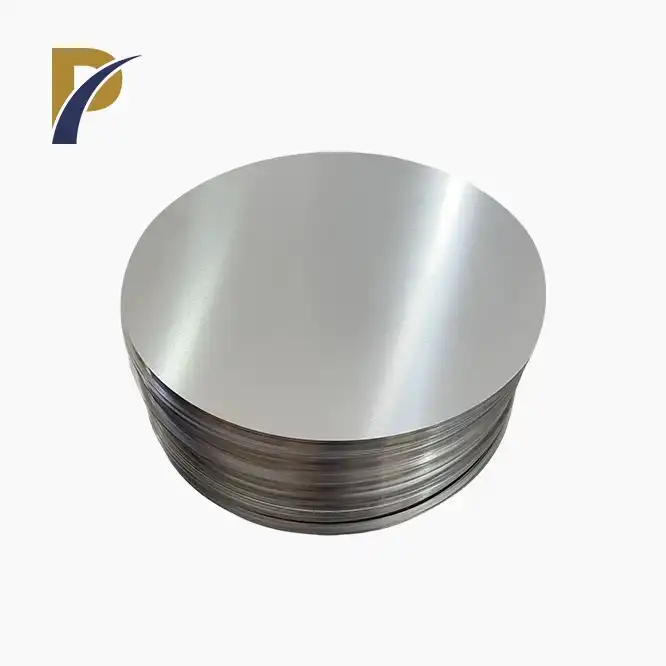

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. has a rich experience in producing non-ferrous and refractory metals. Our main products include tungsten-copper alloy, molybdenum-copper alloy, tungsten-molybdenum alloy, and more. We have been focusing on foreign trade since 2010, providing high-quality products to international markets. Our company integrates manufacturing, R&D, product testing, and inventory management, ensuring top-quality products and services. Our products are exported to countries like Taiwan, Ukraine, South Korea, the USA, Australia, Germany, and Iran, receiving high recognition and evaluations from our customers.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Box Packaging: For maximum protection during transportation.

- Cardboard Packaging: Suitable for smaller, lighter items.

- Foam Fill Packaging: The products are cushioned and protected from shocks.

- Waterproof and Moisture-Proof Packaging: Maintains product integrity during transit.

- Custom Packaging: Tailored to specific customer requirements.

- International Standard Packaging: Complies with global shipping standards.

Shipping Methods

- Sea Freight: Economical for large and heavy shipments.

- Air Freight: Fast and efficient for urgent deliveries.

- Land Transport: Reliable for regional deliveries.

- Multimodal Transport: Combines different transport modes for optimal efficiency.

- Courier Services: Ideal for small, urgent shipments.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Extensive Experience: Over a decade of experience in non-ferrous metal production and export.

- Comprehensive Product Range: Offering over 100 types of non-ferrous metal products.

- Quality Assurance: Rigorous quality control processes ensuring top-quality products.

- Global Reach: Exporting to multiple countries with established customer relationships.

- Advanced Equipment: Equipped with state-of-the-art production and testing facilities.

- Custom Solutions: Providing OEM/ODM services to meet specific customer needs.

- Customer-Centric Approach: Focused on delivering high-quality products and services.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services, allowing customers to customize products to their specific requirements. We support custom designs, specifications, and packaging, ensuring that our products perfectly match our customers' needs.

|

|

FAQ

- What is the maximum operating temperature of SiC heating elements?

- Our electric furnace sic heating element can operate at temperatures up to 1,600°C.

- How do I select the right size and power rating for my application?

- Our technical team can assist you in choosing the appropriate size and power rating based on your specific requirements.

- What are the benefits of using SiC heating elements over other types?

- The products offer high thermal conductivity, excellent durability, and uniform heating, making them ideal for various high-temperature applications.

- Can you provide custom sizes and shapes for SiC heating elements?

- Yes, we offer customizable solutions to meet your specific needs.

- How do you ensure the quality of your SiC heating elements?

- Each element undergoes rigorous testing and quality control processes to ensure it meets industry standards.

Contact us

Are you looking for reliable and high-quality electric furnace sic heating elements for your electric furnace applications? Shaanxi Peakrise Metal Co., Ltd. is your trusted partner. With extensive experience, advanced manufacturing capabilities, and a commitment to quality, we provide the best solutions for your heating needs. Contact us today at info@peakrisemetal.com and let us help you achieve optimal performance in your operations. We look forward to working with you!