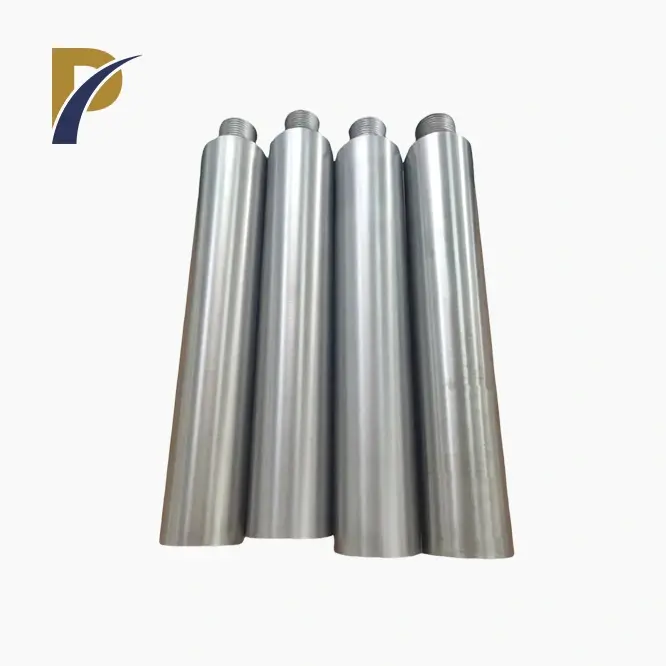

sic rod heater element

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

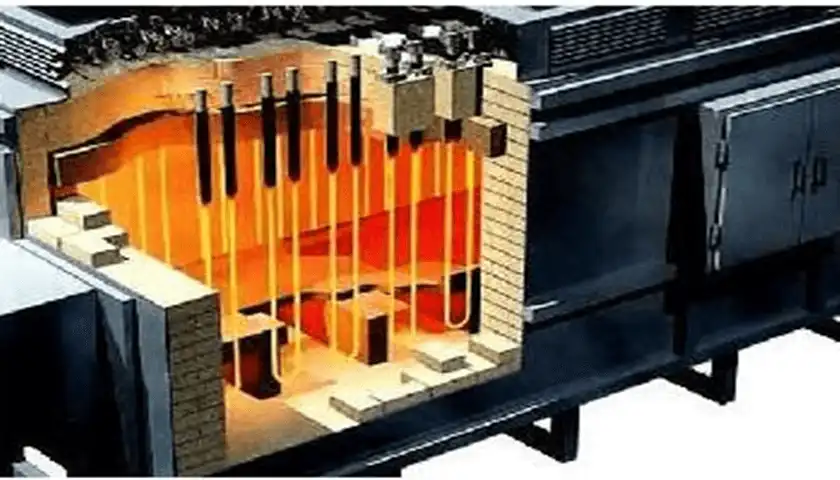

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Sic Rod Heater Element Product Introduction

In high-temperature industrial applications, a crucial component is the silicon carbide (SiC) rod heater element. sic rod heater element are a necessity in furnaces, kilns, and other high-temperature processing equipment due to their exceptional electrical conductivity and thermal resistance. At Shaanxi Peakrise Metal Co., Ltd., we work in assembling great SiC bar radiator components that meet the severe necessities of current modern applications.

Our SiC rod heater elements deliver exceptional performance and dependability because of our commitment to quality, innovation, and expertise in the production of non-ferrous metals and refractory materials. With long periods of involvement with the business, Shaanxi Peakrise Metal Co., Ltd. has set up a good foundation for itself as a confided in provider of SiC bar radiator components, taking care of a worldwide market and giving fitted answers for meet different client needs.

|

|

|

Product Specifications

| Parameter | Value |

|---|---|

| Diameter | 8mm - 54mm |

| Length | 300mm - 1800mm |

| Maximum Operating Temperature | 1600°C |

| Resistance Tolerance | ±20% |

| Density | 3.1g/cm³ |

| Electrical Properties | Value |

|---|---|

| Resistivity at 1000°C | 0.15 - 0.35Ω·cm |

| Voltage | 60V - 110V |

| Power Rating | 1kW - 40kW |

| Maximum Current | 100A |

| Insulation Resistance | >100MΩ |

| Mechanical Properties | Value |

|---|---|

| Flexural Strength | 30 - 50MPa |

| Compressive Strength | 300 - 400MPa |

| Thermal Expansion Coefficient | 4.7 x 10⁻⁶ /°C |

| Thermal Conductivity | 120 - 170W/m·K |

| Hardness | 9.5 (Mohs scale) |

Physical and Chemical Properties

- High Warm Conductivity: ensures the effective distribution of heat.

- Excellent conductivity of electricity: suitable for use with a lot of power.

- High Hardness and Strength: robust and resistant to wear.

- Oxidation Obstruction: Drags out assistance life in high-temperature conditions.

- Protection from Corrosion: endures hostile chemical environments.

|

|

Product Functions

- Operation at High Temperatures: Equipped for working at temperatures up to 1600°C, making it ideal for use in high-temperature heaters and ovens.

- Effective Heat Dispersion: The high warm conductivity guarantees uniform intensity dissemination, working on the proficiency of warming cycles.

- Durability: SiC Heating Element have a long service life, even in demanding applications, thanks to their high strength and hardness.

- Energy conservation: Good electrical conductivity saves money over time because it uses less energy.

- Resistance to Oxidation and Corrosion: SiC rod heater elements are suitable for use in harsh industrial environments, where other materials might fail, thanks to these properties.

Product Applications

- Kilns and industrial furnaces: sic rod heater elements are fundamental in enterprises like ceramics, glass, and metallurgy for high-temperature handling.

- Heat Treatment: used in processes like annealing and sintering that require uniform heating and precise temperature control.

- Chemical Treatment: suitable for chemically corrosive environments, ensuring long-term dependability.

- Semiconductor Assembling: crucial for processes that require temperature stability and high purity.

- Equipment for the Lab: Utilized in high-temperature lab heaters for innovative work purposes.

|

|

Manufacturing Process and Production Workflow

- Selection of Raw Materials: High-virtue silicon carbide is chosen to guarantee ideal execution.

- Blending and Shaping: The unrefined substances are blended and shaped into bars of the ideal aspects.

- Sintering: To obtain the required mechanical and physical properties, the formed rods are sintered at high temperatures.

- Machining and Wrapping up: The SiC Heating Elements are machined to exact particulars and completed to guarantee smooth surfaces and precise aspects.

- Control of Quality: Each rod is rigorously tested and inspected to make sure it meets the requirements.

- Packaging: The completed items are painstakingly pressed to forestall harm during transportation.

|

|

|

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is a seasoned manufacturer of non-ferrous metals like tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. We have developed into a comprehensive non-ferrous metal production company that integrates manufacturing, material research, product testing, stock inventory, and international trade with over a decade of experience. Our goods are sold all over the world, including to Taiwan, South Korea, Ukraine, the United States, Australia, Germany, Iran, and other nations. We have earned high recognition and praise from our clients thanks to our long-term cooperative relationships.

Vacuum annealing furnaces, intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, vacuum annealing furnaces, various rolling mills, wire drawing machines, plasma welding rooms, lathes, milling machines, sawing machines, drilling machines, shears, stamping equipment, cutting equipment, grinders, straightening machines, and CNC machines are just a few of the advanced pieces of machinery that can be found in our manufacturing

Bundling

Wooden Cartons: Secure and solid bundling to forestall harm during transport.

Container Boxes: Convenient for smaller shipments and lightweight.

Froth Cushioning: Gives extra security to forestall breakage.

Packaging that is impervious to water and moisture: ensures that the sic rod heater element is intact and free of corrosion.

Individualized Packaging: tailored solutions to meet the specific needs of the customer.

Compliance with International Standards: Bundling fulfills worldwide delivery guidelines.

Coordinated factors

Ocean Cargo: a good deal for big shipments.

Airship cargo: Rapid and dependable for last-minute orders.

Transport by Land: Adaptable and effective for local deliveries

Transport by Multiple Modes: Consolidates different transportation modes for ideal operations arrangements.

Service for Couriers: Quick and advantageous for more modest bundles.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Us?

Our Extensive Experience: North of 10 years of ability in delivering and sending out non-ferrous metal items.

Complete Selection of Products: Over 100 distinct products that meet a wide range of industrial requirements.

Quality Control: Severe quality control measures guarantee the best expectations.

Advanced Technology: modern manufacturing facilities for precise and effective production.

Global Reach: Items traded to various nations with laid out long haul associations.

A focus on the customer: solutions and services tailored to meet the specific needs of each client.

Advancement and Improvement: Nonstop interest in Research and development for item advancement and improvement.

Team of Professionals: Experienced experts devoted to offering superb assistance and backing.

|

|

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer extensive OEM and ODM administrations to meet your particular requirements. Our group of specialists can work with you to plan and fabricate SiC bar radiator components that meet your accurate details, guaranteeing ideal execution and similarity with your current frameworks. We are here to provide custom services that meet your needs, whether you need custom dimensions, special properties, or packaging solutions.

|

|

Frequently Asked Questions (FAQ)

-

What is the maximum operating temperature of your SiC rod heater elements?

- Our SiC rod heater elements can operate at temperatures up to 1600°C.

-

Can you provide custom dimensions for SiC rod heater elements?

- Yes, we offer OEM and ODM services to manufacture SiC rod heater elements in custom dimensions.

-

What are the packaging options available?

- We offer wooden crates, carton boxes, foam padding, waterproof and moisture-proof packaging, and customized packaging solutions.

-

How do you ensure the quality of your products?

- We have stringent quality control measures in place, including raw material inspection, in-process testing, and final product inspection.

-

What are your shipping options?

- We provide various shipping options, including sea freight, air freight, land transport, multimodal transport, and courier services.

Contact us

Is it true that you are searching for great sic rod heater element for your modern applications? Shaanxi Peakrise Metal Co., Ltd. is the only place you need to go. Our knowledgeable staff is ready to meet your specific requirements and create bespoke solutions. For more information about how our SiC rod heater elements can help you achieve optimal performance, please get in touch with us right away at info@peakrisemetal.com. Join us and discover the difference in service, dependability, and quality.

YOU MAY LIKE

-

VIEW MOREsic heating elements

VIEW MOREsic heating elements -

VIEW MOREelectric furnace sic heating element

VIEW MOREelectric furnace sic heating element -

VIEW MORElanthanated molybdenum rod

VIEW MORElanthanated molybdenum rod -

VIEW MOREmolybdenum wire drawing

VIEW MOREmolybdenum wire drawing -

VIEW MOREpure tantalum sheet/plate

VIEW MOREpure tantalum sheet/plate -

VIEW MOREmetal molybdenum grinding plate

VIEW MOREmetal molybdenum grinding plate -

VIEW MOREtitanium tig welding rod

VIEW MOREtitanium tig welding rod -

VIEW MORE50 diameter molybdenum elecrtode

VIEW MORE50 diameter molybdenum elecrtode