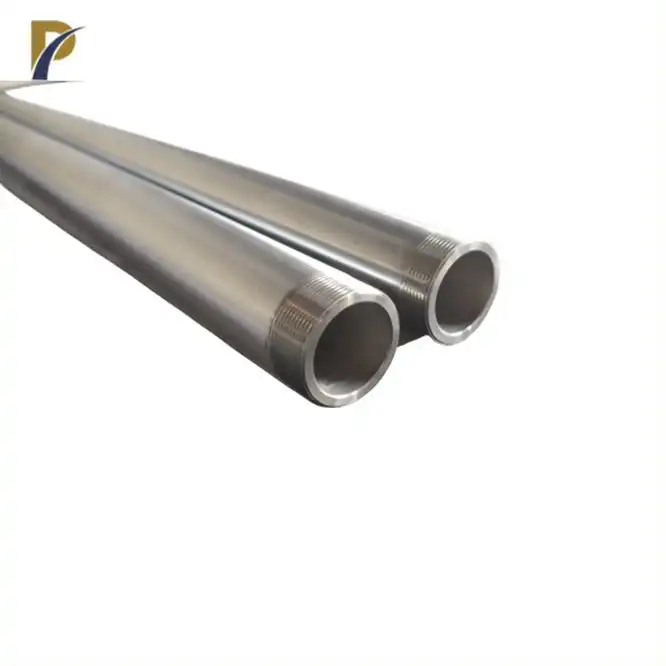

high temperature furnace tungsten crucible

Material: Pure Tungsten

Density: 17.8 G/cm3~19.3 G/cm3

Purity: 99.95%

Diameter: 30~500mm

Thickness:2~30mm

Height:<1000mm

Roughness:<1.6

Process method: Machining, sintering, welding

Application: vacuum coating industry, sintering furnace sintering, vacuum annealing industry.

PRODUCT DESCRIPTION

High Temperature Furnace Tungsten Crucible Introduction

Shaanxi Peakrise Metal Co., Ltd. proudly presents our high temperature furnace tungsten crucible, an industry-leading product designed to withstand extreme thermal environments. Our tungsten crucibles are renowned for their exceptional performance in high-temperature applications, thanks to tungsten's superior melting point, excellent thermal conductivity, and remarkable resistance to corrosion and wear.

Product Parameters

| Parameter | Value |

|---|---|

| Purity | ≥ 99.95% |

| Density | 19.3 g/cm³ |

| Melting Point | 3422°C (6192°F) |

| Working Temperature | ≤ 2800°C (5072°F) |

| Thermal Conductivity | 173 W/m·K at 300K |

| Electrical Resistivity | 5.5 µΩ·cm at 20°C |

| Dimension Range | Value |

|---|---|

| Diameter | 10-500 mm |

| Height | 10-600 mm |

| Wall Thickness | 1-10 mm |

| Surface Roughness | Ra ≤ 1.6 μm |

| Tolerance | ±0.05 mm |

| Mechanical Properties | Value |

|---|---|

| Tensile Strength | 700-900 MPa |

| Elongation | 10-20% |

| Hardness | ≥ 200 HV |

| Modulus of Elasticity | 410 GPa |

| Fracture Toughness | 8-10 MPa·√m |

|

|

Physical and Chemical Properties

High temperature furnace tungsten crucible is characterized by its extremely high melting point, which makes it suitable for high-temperature furnace applications. It has excellent thermal and electrical conductivity, allowing efficient heat distribution and energy transfer. Tungsten is highly resistant to corrosion and oxidation, even at elevated temperatures, ensuring longevity and reliability in demanding environments.

|

|

High Temperature Furnace Tungsten Crucible Functions

- High Melting Point: high temperature furnace tungsten crucible can withstand temperatures up to 3422°C, making them ideal for high-temperature furnaces.

- Excellent Thermal Conductivity: Efficient heat distribution ensures uniform temperature profiles and energy efficiency.

- Corrosion and Wear Resistance: Prolonged lifespan even under harsh chemical and physical conditions.

- Dimensional Stability: Maintains structural integrity at high temperatures, ensuring consistent performance.

- High Purity: Minimizes contamination in sensitive applications, ensuring product purity and quality.

Product Applications

- Aerospace Industry: Used in the production of high-temperature components and coatings, crucial for spacecraft and aircraft engines.

- Electronics Manufacturing: Essential for the production of semiconductors and electronic components, ensuring high precision and reliability.

- Chemical Processing: Employed in reactors and furnaces for high-purity chemical synthesis and processing.

- Metal Casting and Melting: Ideal for melting high-purity metals and alloys, ensuring minimal contamination.

- Defense Applications: Used in the production of defense-related components that require high-temperature resistance and durability.

|

|

Production Process and Manufacturing Techniques

- Material Selection: High-purity high temperature furnace tungsten crucible is selected and inspected for quality.

- Powder Metallurgy: Tungsten powder is pressed and sintered to form a solid billet.

- Machining: The billet is precisely machined to the desired dimensions using advanced CNC equipment.

- Inspection: Each crucible undergoes rigorous quality control tests to ensure compliance with specifications.

- Finishing: Surface treatments and polishing are applied to achieve the required surface roughness and dimensional accuracy.

- Packaging: Finished crucibles are carefully packaged to prevent damage during transportation.

|

|

|

Our Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. boasts state-of-the-art manufacturing facilities equipped with cutting-edge technology. Our High-Temperature Tungsten Crucible for Induction capabilities include intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, and plasma electron beam melting furnaces. Our comprehensive range of equipment allows us to produce high-quality tungsten crucibles and other non-ferrous metal products with precision and efficiency. Our commitment to research and development, coupled with stringent quality control measures, ensures that our products meet the highest industry standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

- Wooden Box Packaging: Provides robust protection against physical damage during transportation.

- Carton Packaging: Suitable for smaller or less fragile items, ensuring safe delivery.

- Foam Filling Packaging: Prevents movement and absorbs shocks, safeguarding delicate components.

- Waterproof and Moisture-Proof Packaging: Protects against environmental factors during transit.

- Custom Packaging: Tailored solutions to meet specific customer requirements, ensuring optimal protection.

- Compliance with International Standards: All packaging adheres to international shipping and safety regulations.

Logistics Options

- Sea Freight: Cost-effective for large shipments with flexible delivery schedules.

- Air Freight: Faster delivery for time-sensitive shipments, ensuring quick turnaround.

- Land Transport: Reliable and efficient for regional deliveries.

- Multimodal Transport: Combining different transport modes for optimized logistics solutions.

- Courier Services: Ideal for small, urgent deliveries with real-time tracking and fast service.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Expertise and Experience: Over a decade of experience in non-ferrous metal production, ensuring high-quality products.

- Comprehensive Product Range: A wide variety of non-ferrous metal products, including alloys and custom solutions.

- Global Reach: Established relationships with customers worldwide, ensuring reliable supply and support.

- Advanced Manufacturing Facilities: State-of-the-art equipment and processes for precise and efficient production.

- Quality Assurance: Rigorous quality control measures to ensure product reliability and performance.

- Customer-Centric Approach: Dedicated to meeting customer needs with tailored solutions and exceptional service.

- Innovation and R&D: Continuous investment in research and development to stay at the forefront of industry advancements.

- Sustainable Practices: Commitment to environmentally friendly production methods and sustainability.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM and ODM services, providing customized tungsten crucible solutions to meet specific customer requirements. Our experienced team works closely with clients to design and manufacture products that match their unique needs, ensuring optimal performance and satisfaction.

|

|

Frequently Asked Questions (FAQ)

- What is the maximum operating temperature for your tungsten crucibles?

- Our tungsten crucibles can operate at temperatures up to 2800°C (5072°F).

- Can you provide custom dimensions for tungsten crucibles?

- Yes, we offer OEM services and can manufacture crucibles to your specific dimensions.

- What is the lead time for a typical order?

- Lead times vary based on order size and specifications, but we strive to deliver within 4-6 weeks.

- Do you offer technical support for your products?

- Yes, our team provides comprehensive technical support and guidance for the use and maintenance of our products.

- How do you ensure the quality of your tungsten crucibles?

- We implement stringent quality control measures, including material inspection, dimensional verification, and performance testing.

Contact us

Ready to enhance your high-temperature applications with our Tungsten Induction Crucible? Contact Shaanxi Peakrise Metal Co., Ltd. today to discuss your requirements and discover how our expertise can benefit your operations. Reach out to us at info@peakrisemetal.com and join the ranks of satisfied customers worldwide. Let's collaborate to achieve excellence in your industry!