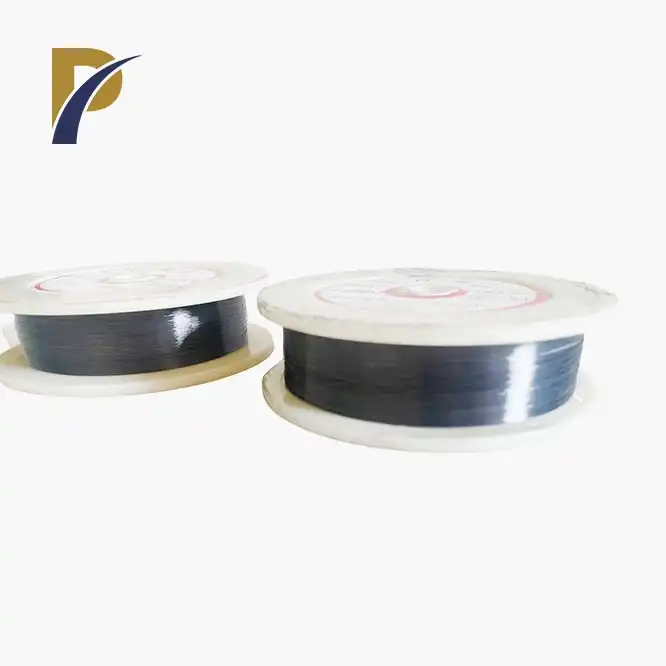

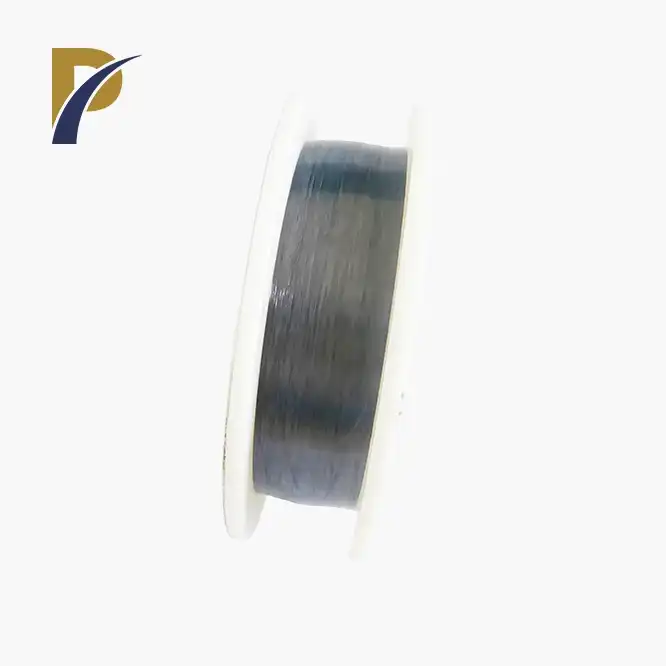

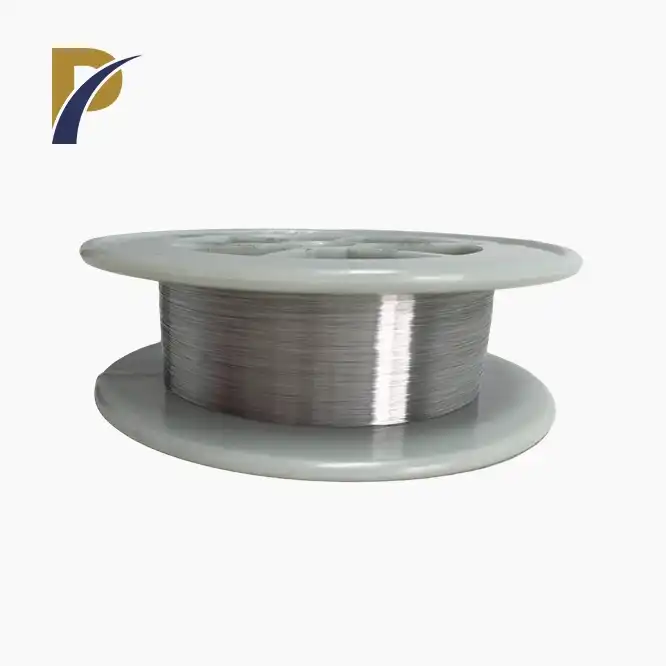

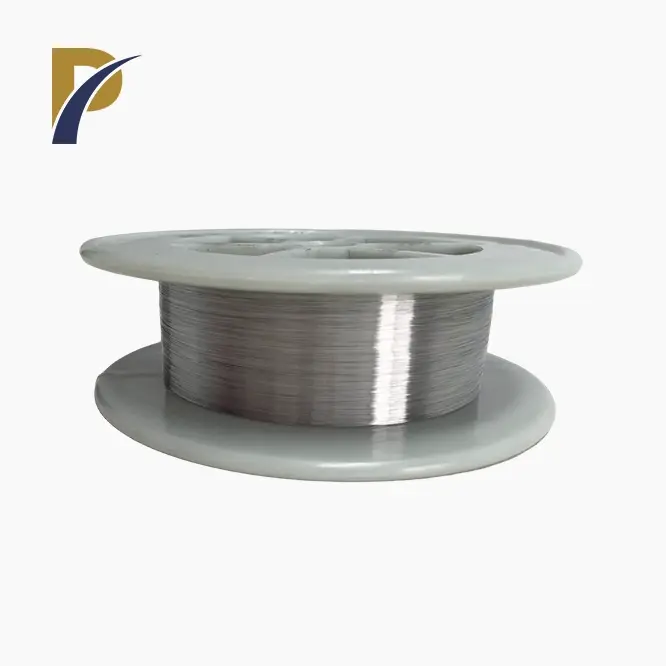

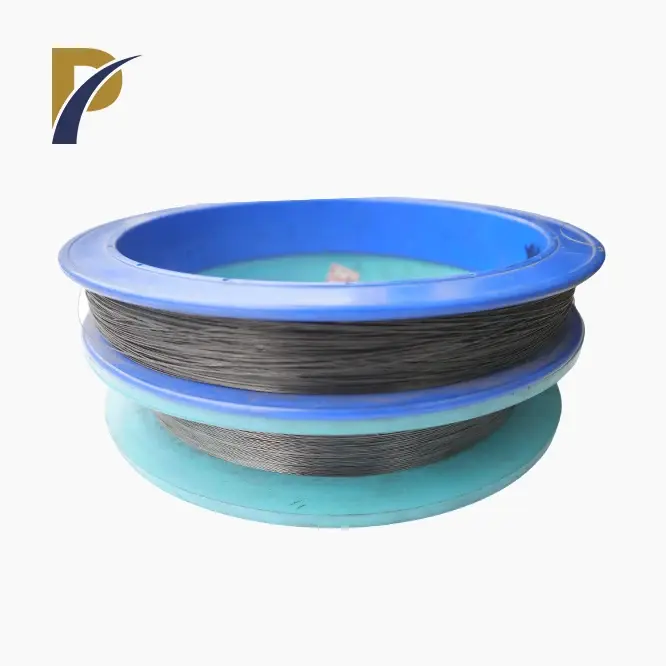

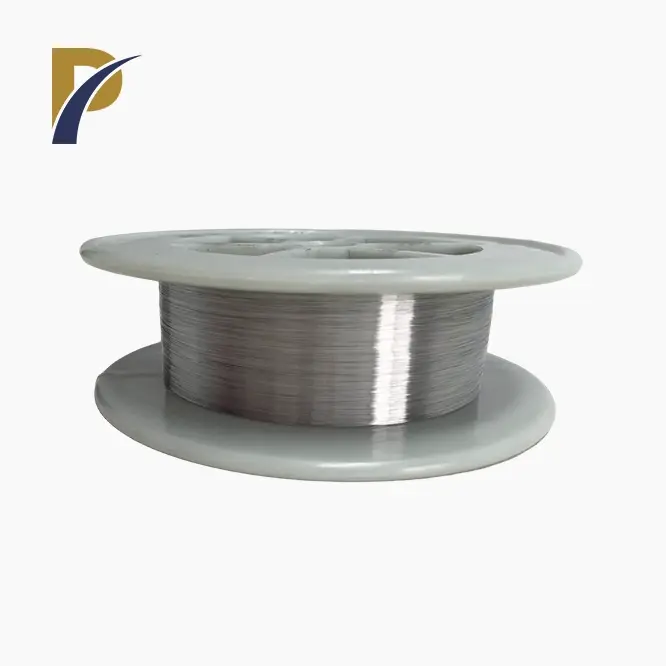

pure tungsten wire

Material: Pure Tungsten

Purity: >99.95%

Melting Point : 3410℃

Tensile Strength: ≥980MPa

Elongation: ≥3.5%

Density: 19.3 G/cm3

Surface: Bright,Black

Diameter: 0.265mm,0.3mm,0.15mm,0.2mm Etc.

Application: Photoelectric Industry

PRODUCT DESCRIPTION

Pure Tungsten Wire Introduction

Shaanxi Peakrise Metal Co., Ltd. is a main provider of pure tungsten wire, offering high-quality items to address the issues of different businesses around the world. Tungsten wire, known for its outstanding properties, is a basic part in various high-temperature applications because of its momentous dissolving point, strength, and warm conductivity. As a devoted provider, we guarantee that our tungsten wire fulfills the highest guidelines of value and execution, going with it an optimal decision for requesting modern applications.

Product Specifications

Physical Properties

| Property | Value |

|---|---|

| Purity | 99.95% |

| Density | 19.3 g/cm³ |

| Melting Point | 3422°C |

| Boiling Point | 5930°C |

| Thermal Conductivity | 173 W/m·K |

| Electrical Resistivity | 5.65 µΩ·cm |

| Tensile Strength | 1510 MPa |

Dimensional Specifications

| Diameter (mm) | Tolerance (mm) | Length (m) |

|---|---|---|

| 0.10 | ±0.005 | Up to 200 |

| 0.20 | ±0.010 | Up to 200 |

| 0.30 | ±0.015 | Up to 200 |

Mechanical Properties

| Property | Value |

|---|---|

| Elastic Modulus | 400 GPa |

| Poisson's Ratio | 0.28 |

| Hardness | 350 HV |

| Yield Strength | 800 MPa |

|

|

Physical and Chemical Properties

Our tungsten wire is renowned for its exceptional physical and chemical properties, making it indispensable in various high-performance applications. Its high melting point of 3422°C ensures stability at extreme temperatures. Tungsten's density of 19.3 g/cm³ provides significant strength and durability. The wire's thermal conductivity of 173 W/m·K and electrical resistivity of 5.65 µΩ·cm highlight its efficient heat and electrical conduction capabilities.

|

|

Product Functions

- High-Temperature Stability: Pure tungsten wire retains its mechanical properties at elevated temperatures, making it ideal for use in high-temperature environments such as furnaces and aerospace applications.

- Durability and Strength: With its high tensile strength and density, tungsten wire is incredibly durable and can withstand harsh conditions, ensuring long-lasting performance.

- Excellent Thermal Conductivity: Tungsten wire efficiently conducts heat, making it suitable for applications requiring rapid heat dissipation.

- Superior Electrical Conductivity: Its low electrical resistivity makes tungsten wire perfect for use in electronic components and electrical contacts.

- Corrosion Resistance: Tungsten wire exhibits excellent resistance to corrosion, enhancing its longevity and reliability in various industrial settings.

Product Applications

- Lighting Industry: pure tungsten wire is extensively used in incandescent light bulbs and halogen lamps due to its ability to withstand high temperatures and emit bright light.

- Electronics: The superior electrical conductivity of tungsten wire makes it ideal for use in electronic devices, including semiconductors and integrated circuits.

- Aerospace: Tungsten wire's high melting point and strength make it essential for aerospace components that must endure extreme conditions.

- Medical Equipment: Tungsten wire is utilized in medical devices, such as X-ray tubes and radiation shields, owing to its high density and radiation absorption capabilities.

- Industrial Heating: Tungsten wire is employed in industrial furnaces and high-temperature processing equipment due to its stability at elevated temperatures.

|

|

Manufacturing Process and Production Flow

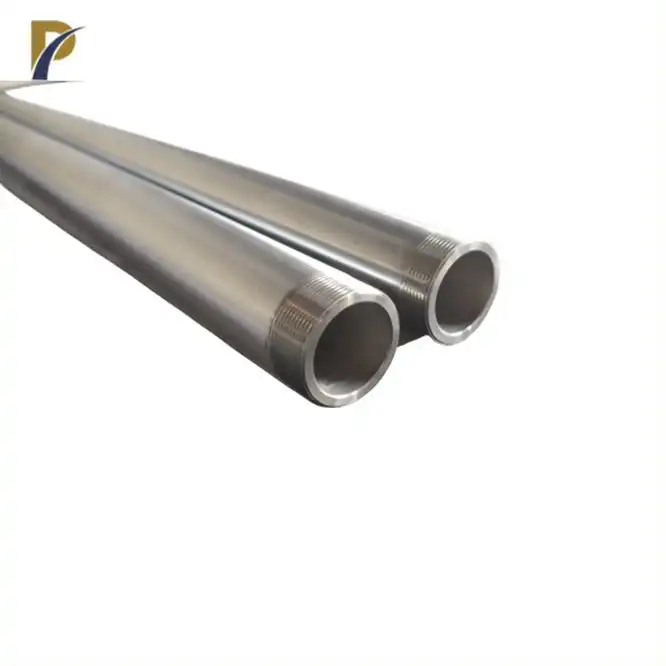

At Shaanxi Peakrise Metal Co., Ltd., our Pure Tungsten Tube is manufactured through a meticulous process that ensures superior quality and consistency. The production flow includes:

- Raw Material Selection: We start with high-purity tungsten powder, carefully selected to meet our stringent standards.

- Powder Processing: The tungsten powder is pressed and sintered to form billets, which are then subjected to rolling and forging to achieve the desired dimensions.

- Wire Drawing: The billets are drawn into fine wires using advanced wire drawing machines, ensuring precise diameter and uniformity.

- Annealing: The drawn wires undergo a vacuum annealing process to enhance their mechanical properties and relieve internal stresses.

- Quality Control: Rigorous testing and inspection are conducted at every stage of production to ensure that our tungsten wire meets the highest quality standards.

- Packaging: The finished wires are carefully packaged to prevent damage during transportation and storage.

|

|

|

Factory Overview

Shaanxi Peakrise Metal Co., Ltd. boasts a state-of-the-art manufacturing facility equipped with advanced machinery and technology. Our factory features intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, vacuum annealing furnaces, and various rolling mills and wire drawing machines. Our commitment to innovation and quality is reflected in our investment in cutting-edge equipment and continuous improvement of our production processes.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging

- Wooden Box Packaging: Provides robust protection during transit.

- Carton Packaging: Suitable for smaller quantities and lighter shipments.

- Foam Filling Packaging: Ensures cushioning and protection from impact.

- Waterproof and Moisture-Proof Packaging: Prevents damage from moisture and environmental factors.

- Custom Packaging: Tailored to meet specific customer requirements.

- International Standard Packaging: Complies with global shipping standards.

Logistics

- Sea Freight: Cost-effective solution for large and heavy shipments.

- Air Freight: Fast and reliable for urgent and high-value consignments.

- Land Transport: Flexible and efficient for regional deliveries.

- Multimodal Transport: Combines various transportation modes for optimal efficiency.

- Courier Services: Suitable for small packages and expedited deliveries.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Extensive Experience: Over a decade of expertise in non-ferrous metal production.

- High-Quality Products: Commitment to delivering products that meet the highest industry standards.

- Comprehensive Services: From manufacturing to material research and development, product testing, and stock inventory.

- Global Reach: Products exported to numerous countries with established long-term cooperative relationships.

- State-of-the-Art Equipment: Advanced machinery and technology for superior product quality.

- Customer-Centric Approach: Focus on providing high-quality products and services tailored to customer needs.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM and ODM services to meet the specific needs of our clients. Our experienced team works closely with customers to develop customized solutions, from product design and development to manufacturing and packaging. We support various custom processing services, ensuring that our pure tungsten wire meets the unique requirements of each application.

|

|

FAQ

-

What is the purity of your tungsten wire?

- Our High-Strength Tungsten Tube has a purity of 99.95%, ensuring high performance and reliability.

-

Can you provide custom sizes and lengths?

- Yes, we offer customized sizes and lengths to meet your specific requirements.

-

What are the packaging options for tungsten wire?

- We offer various packaging options, including wooden boxes, cartons, foam filling, waterproof packaging, and custom packaging.

-

How do you ensure the quality of your pure tungsten wire?

- We conduct rigorous quality control at every stage of production, including raw material selection, wire drawing, annealing, and final inspection.

-

What are your shipping options?

- We provide sea freight, air freight, land transport, multimodal transport, and courier services to meet your delivery needs.

Contact us

Are you looking for a reliable supplier of tungsten wire? Look no further than Shaanxi Peakrise Metal Co., Ltd. We are dedicated to providing high-quality pure tungsten wire and exceptional customer service. Contact us today to discuss your requirements and find out how we can meet your needs. Email us at info@peakrisemetal.com. We look forward to collaborating with you!