molybdenum in x ray tube

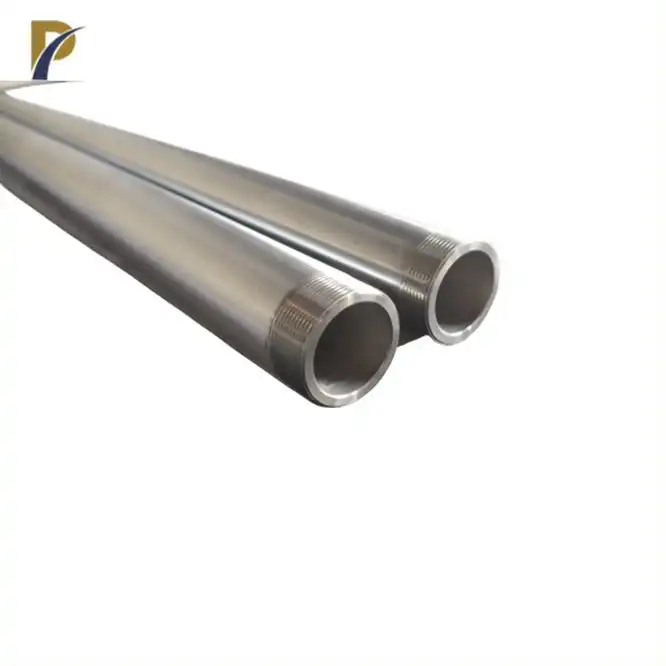

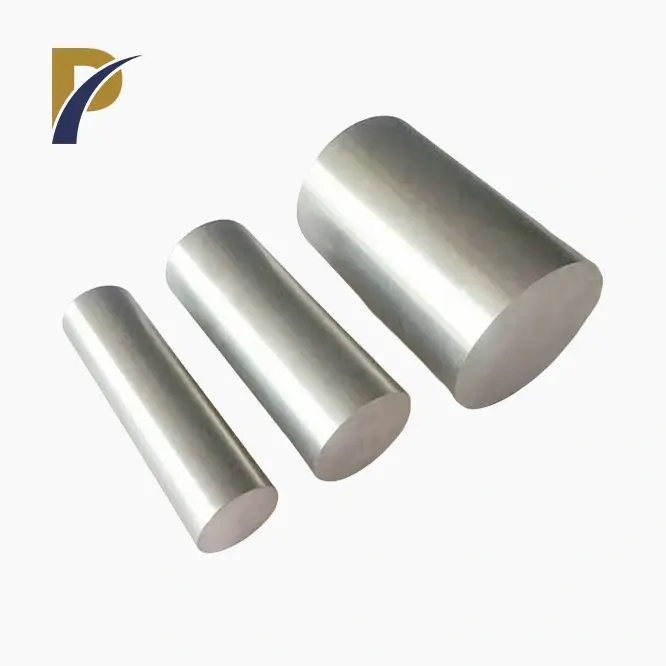

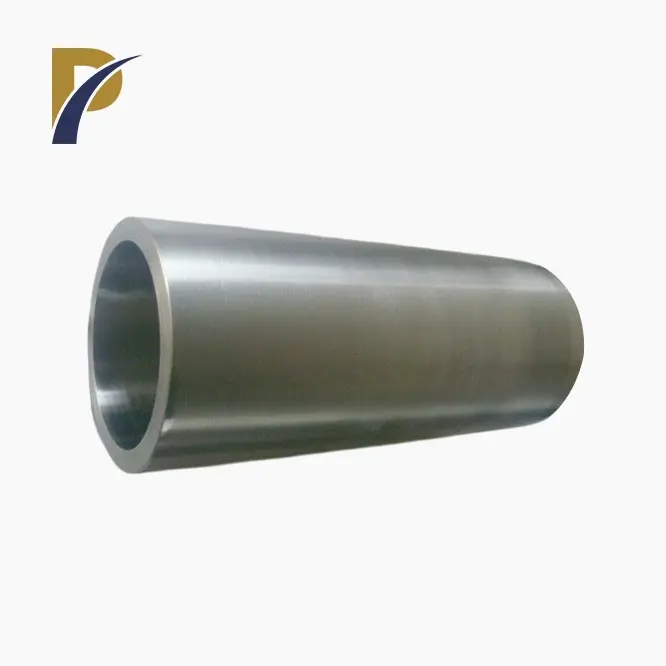

Material: Molybdenum And Molybdenum Alloy

Purity: 99.95%

Density: 10.2g/cm3

Out Diameter: ≤250mm

Wall Thickness: 3~25mm

Length: ≤2700mm

Surface: Bright Advantage: Excellent electrical conductivity,Excellent thermal conductivity Application: electric vacuum industry,TFT-LCD industry.

PRODUCT DESCRIPTION

Molybdenum In X Ray Tube Product Introduction

Molybdenum in x ray tube, where its high melting point and excellent thermal conductivity ensure reliable performance under extreme conditions. Shaanxi Peakrise Metal Co., Ltd. specializes in supplying high-quality molybdenum products tailored for X-ray tube applications, meeting stringent industry standards for efficiency and durability.

Product Specifications

| Property | Value |

|---|---|

| Purity | 99.95% |

| Density | 10.2 g/cm³ |

| Melting Point | 2,623°C |

| Thermal Conductivity | 138 W/m·K |

|

|

Physical and Chemical Properties

Molybdenum exhibits remarkable mechanical strength and stability at high temperatures, crucial for the sustained operation of Molybdenum X-Ray Tube in medical and industrial applications. Its resistance to corrosion ensures longevity and reliability in demanding environments.

|

|

Product Features

- High Thermal Conductivity: Efficient heat dissipation improves tube longevity.

- Excellent Mechanical Strength: Withstands mechanical stress and vibration.

- Corrosion Resistance: Ensures durability in various operating conditions.

- Precision Machining: Allows intricate designs for optimal tube performance.

Product Applications

- Medical Imaging: Essential component in medical X-ray machines.

- Industrial Non-Destructive Testing: Ensures accurate flaw detection.

- Research and Development: Supports advancements in scientific instrumentation.

|

|

Manufacturing Process

In our manufacturing process, we utilize cutting-edge facilities that are specifically tailored to meet the rigorous demands of producing molybdenum in x ray tube applications. At the core of our operations are vacuum arc melting furnaces, which play a pivotal role in ensuring the purity and quality of our materials. These furnaces create a controlled environment devoid of contaminants by melting molybdenum within a vacuum chamber. This process prevents oxidation and maintains the integrity of the material's chemical composition, resulting in high-purity molybdenum ingots and components.

Our precision machining equipment further enhances our manufacturing capabilities. This includes CNC machining centers, grinding machines, and specialized tools designed for molybdenum processing. These tools enable us to achieve precise dimensions, tight tolerances, and smooth surface finishes essential for the performance and longevity of X-ray tube components.

Throughout our manufacturing process, quality control is paramount. We employ rigorous testing and inspection protocols to ensure that each molybdenum product meets the highest industry standards for X-ray tube applications. This includes testing for dimensional accuracy, material purity, mechanical properties, and resistance to thermal stress.

By leveraging these advanced technologies and meticulous processes, we uphold our commitment to delivering molybdenum products of exceptional quality and reliability. Our dedication to innovation and quality assurance enables us to meet the specialized needs of our customers in the medical, industrial, and scientific sectors who rely on precise and durable materials for their X-ray tube applications.

|

|

|

Why Choose Us

Shaanxi Peakrise Metal Co., Ltd. distinguishes itself with:

- Extensive Industry Experience: Over a decade of expertise in non-ferrous metal production.

- Advanced Manufacturing Capabilities: State-of-the-art equipment for precise and reliable production.

- Global Reach: Trusted partnerships across Taiwan, Ukraine, USA, and beyond.

- Customization Services: Tailored solutions to meet specific client requirements.

|

OEM Services

We offer comprehensive OEM/ODM services, collaborating closely with clients to develop customized molybdenum in x ray tube solutions that meet exact specifications.

|

|

FAQs

-

What is the purity level of your molybdenum in x ray tube?

- Our Molybdenum X-Ray Tube purity is consistently 99.95%.

-

Can you customize molybdenum shapes for specific applications?

- Yes, we provide tailored machining solutions for diverse industry needs.

-

How do you ensure product quality?

- Rigorous quality control measures and in-house testing facilities validate product excellence.

-

What industries do you primarily serve?

- We cater to medical, industrial, and scientific sectors requiring high-performance molybdenum components.

-

Do you provide international shipping?

- Yes, we offer global logistics solutions including sea, air, and courier services.

Packaging and Logistics

Packaging:

- Wooden crates, cardboard boxes, foam-filled packaging, waterproof custom solutions.

Logistics:

- Sea freight, air freight, land transportation, multimodal transport, expedited delivery services.

|

|

|

|

|

|

|

|

|

|

Contact Us

For inquiries about our molybdenum in x ray tube, please contact us at info@peakrisemetal.com. Partner with Shaanxi Peakrise Metal Co., Ltd. for reliable molybdenum solutions tailored to your needs.