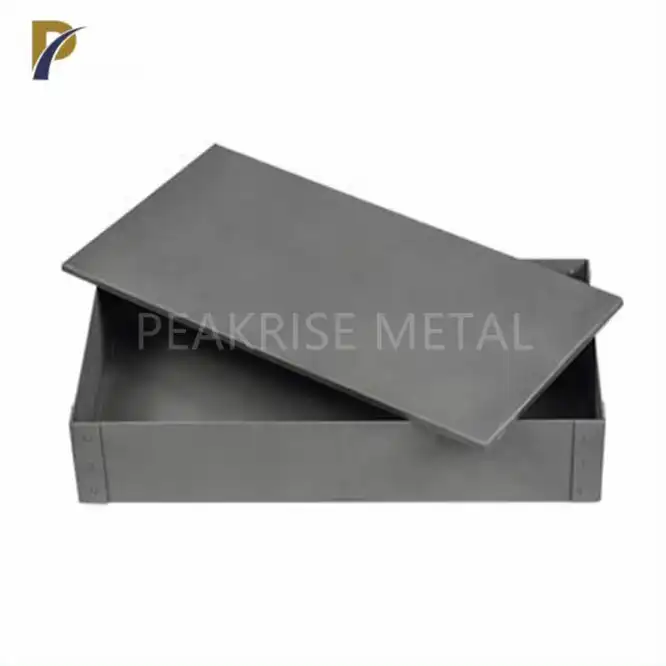

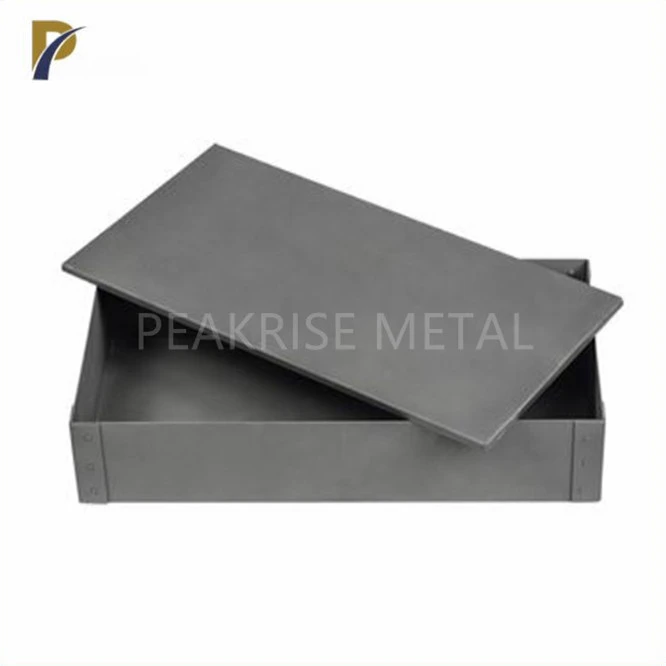

tungsten sintering boat

Purity: 99.95%

Density: 19.3 G/cm3

Thermal Expansion Coefficient: 4.5×10^-6/℃

Surface:Alkaline Washing,Polished

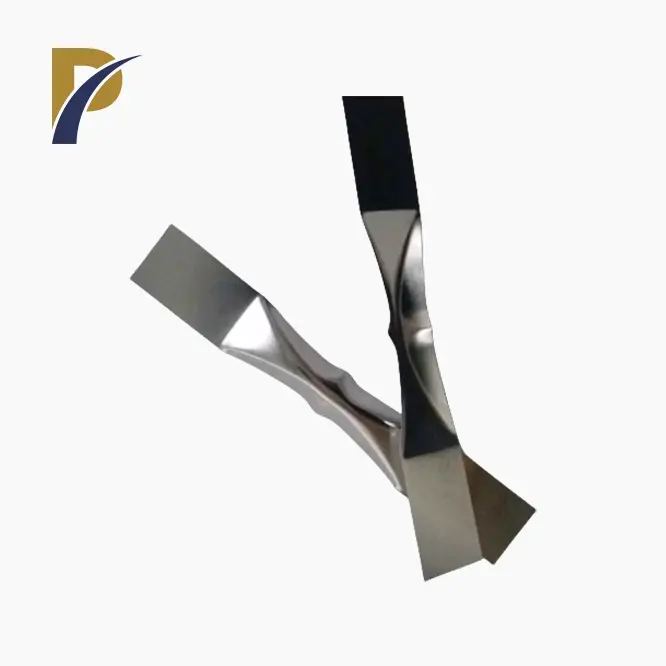

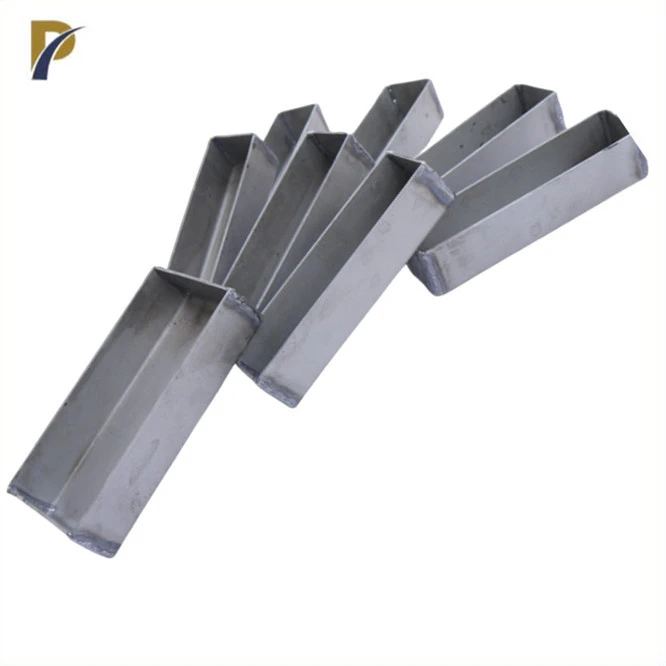

Process Method:Welding,riveting,folding,stamping

Use Temperature: 2200℃~2800℃

PRODUCT DESCRIPTION

Tungsten Sintering Boat Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your reliable partner for premium tungsten sintering boats. As a distinguished leader in the non-ferrous metal sector, we are committed to delivering durable, precision-engineered tungsten that exceed the expectations of cutting-edge industrial applications. Our unwavering dedication to innovation and quality ensures that our customers receive the best solutions for their specific needs, enhancing their manufacturing processes and driving efficiency.

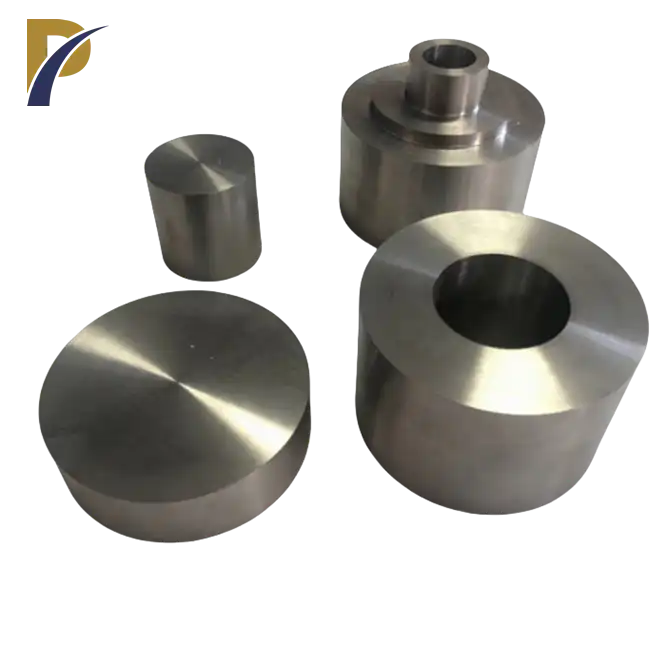

Product Specifications

| Parameter | Description |

|---|---|

| Material | Tungsten (W) |

| Purity | ≥ 99.95% |

| Density | 19.3 g/cm³ |

| Melting Point | 3,422°C |

| Dimensions | Customizable (Length × Width × Height) |

| Typical Dimensions | 150 mm × 30 mm × 10 mm (customizable) |

| Operating Temperature | Up to 2,800°C |

| Thermal Conductivity | 173 W/m·K (at 20°C) |

| Electrical Resistivity | 5.5 μΩ·cm |

| Coefficient of Thermal Expansion | 4.5 × 10⁻⁶ /K (20°C - 1,600°C) |

| Surface Condition | Machined, Ground, or Polished |

| Mechanical Properties | High strength and ductility at elevated temperatures |

| Tensile Strength | 500 - 700 MPa |

| Manufacturing Process | Powder metallurgy and sintering |

| Corrosion Resistance | Excellent resistance to most acids and alkalis |

| Packaging | Vacuum-sealed or as per customer request |

| Applications | High-temperature sintering, metal processing, etc. |

|

|

Physical and Chemical Properties

Our Seamless Tantalum Pipe Tube are renowned for their exceptional thermal stability, high density, and remarkable resistance to corrosion and thermal shock. These superior attributes render them perfectly suited for managing high-temperature processes with unwavering precision and reliability. Engineered with meticulous attention to detail, our boats are designed to withstand the rigors of demanding applications, ensuring consistent performance and longevity. By leveraging the latest technology and manufacturing techniques, we guarantee that our products meet the highest standards of durability and efficiency, thus providing our clients with a competitive edge in their respective industries.

|

|

Tungsten Sintering Boat Features

- High purity tungsten sintering boat ensures minimal contamination.

- Excellent thermal and electrical conductivity properties.

- Precision-engineered for dimensional accuracy and durability.

- Resistant to oxidation and chemical degradation.

- Designed to withstand extreme temperatures without deformation.

Tungsten Sintering Boat Applications

- Semiconductor manufacturing: Used in the production of silicon wafers.

- Thermal evaporation processes: Essential for thin film deposition.

- Metallurgical applications: Crucial for high-temperature material processing.

- Research and development: Facilitates experimentation in controlled environments.

|

|

Manufacturing Process

Our tungsten sintering boats are meticulously crafted using state-of-the-art techniques such as vacuum sintering and precision machining, which are pivotal in achieving the highest standards of product integrity. Each and every product is meticulously subjected to a stringent quality control process, ensuring that they consistently deliver exceptional performance and unparalleled reliability in the most demanding applications. By adhering to these rigorous standards, we guarantee that our products will meet and often exceed the expectations of our clients, providing them with a dependable tool for their high-temperature processing needs. This commitment to excellence in both manufacturing and quality assurance is what sets us apart in the non-ferrous metal industry.

|

|

|

Why Choose Us

- Expertise: Over a decade of experience in non-ferrous metal production.

- Quality Assurance: ISO-certified processes guarantee superior products.

- Customization: OEM and ODM services available to meet specific client needs.

- Global Reach: Extensive export experience with a strong presence in international markets.

- Customer Focus: Dedicated to providing exceptional service and support.

|

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer comprehensive OEM services, collaborating closely with clients to develop customized tungsten solutions that meet unique specifications and performance requirements.

|

|

FAQ

- What is the maximum temperature resistance of your products?

- Our boats can withstand temperatures up to 2800°C.

- Do you provide customized sizes and shapes?

- Yes, we specialize in tailor-made products to fit specific application needs.

- Are your products suitable for use in vacuum environments?

- Absolutely, our Tantalum Seamless Tube are vacuum-compatible.

- How do you ensure product quality?

- We implement stringent quality control measures at every stage of production.

- What are your lead times for bulk orders?

- Lead times vary based on order size and customization requirements; contact us for details.

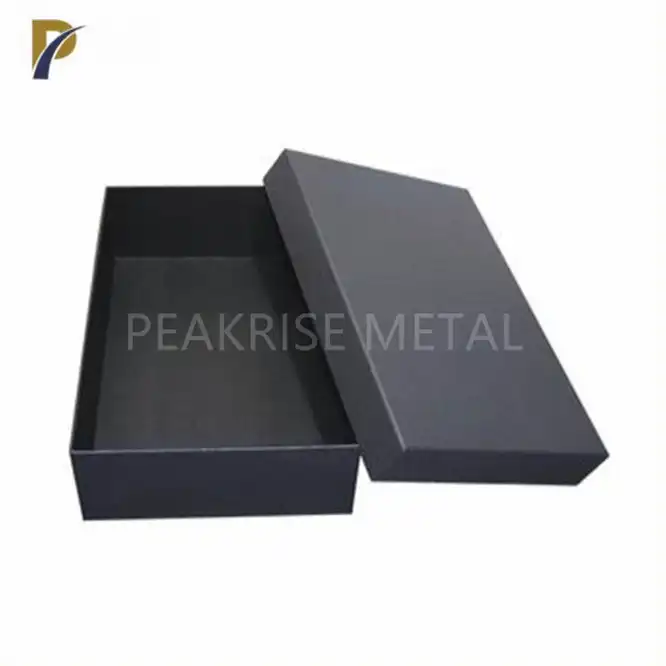

Packaging

Our products are carefully packaged to ensure safe transit:

- Wooden crates for large shipments.

- Cardboard boxes for smaller orders.

- Foam padding to prevent damage during handling.

- Waterproof and moisture-resistant packaging.

- Custom packaging available upon request, meeting international standards.

Logistics

We offer flexible shipping options:

- Sea freight for economical large-scale transportation.

- Air freight for time-sensitive deliveries.

- Land transportation and multimodal solutions.

- Expedited courier services for urgent shipments.

|

|

|

|

|

|

|

|

|

|

Contact Us

Ready to elevate your industrial processes with our premium tungsten sintering boats? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com. Our team is committed to meeting your tungsten product needs with excellence.