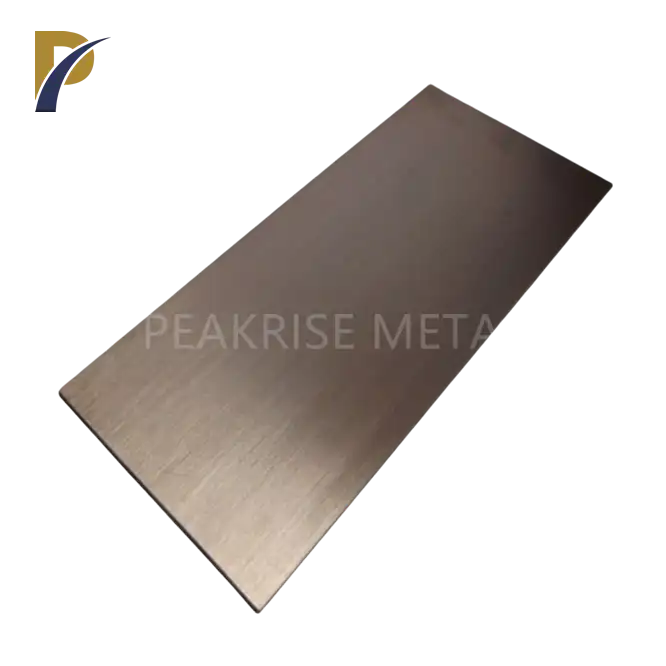

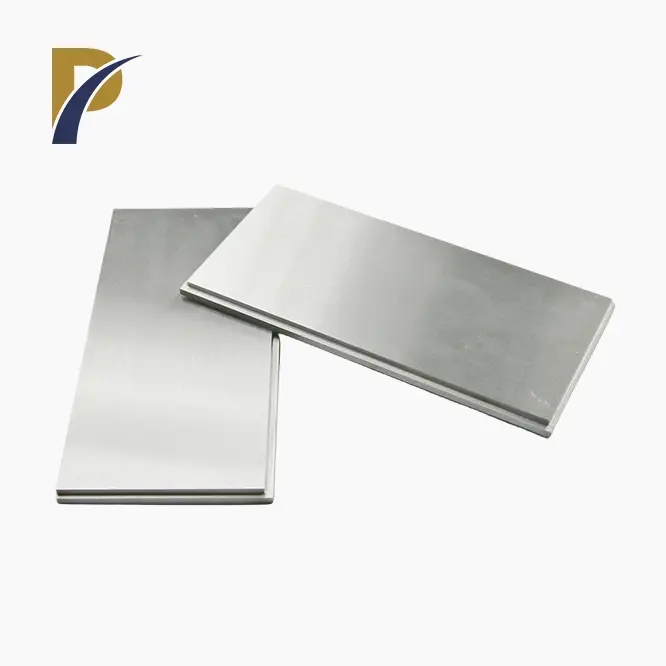

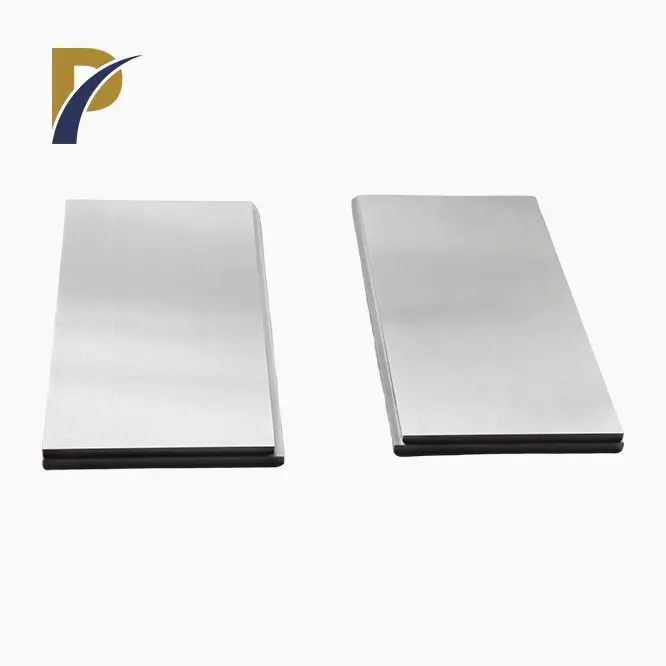

copper tungsten plate

Sheet Material: Tungsten Copper Alloy

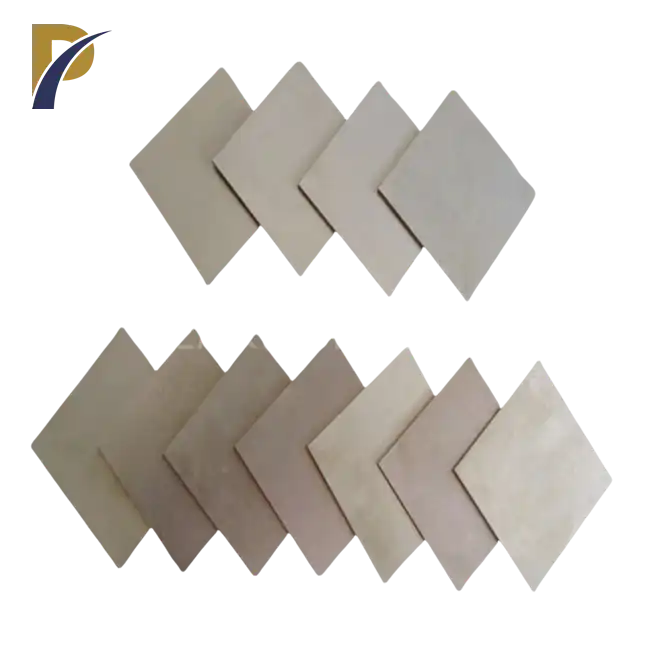

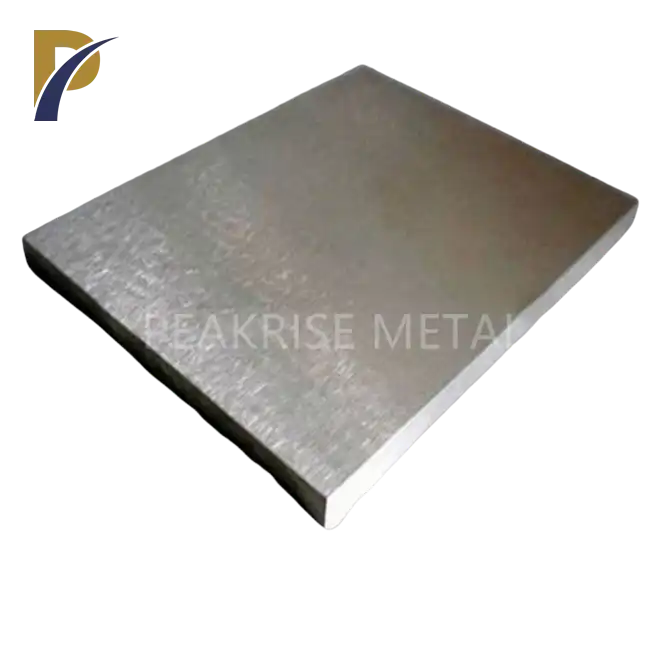

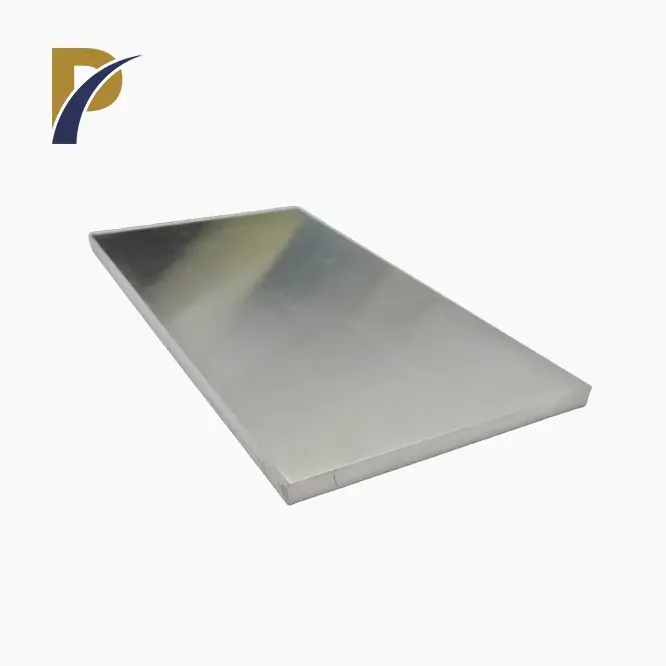

Shape: Plate

Thickness: 2~50mm

Width: 100~200mm

Length: 100~300mm

MOQ: 1pc

Export Port: Any Port In China

PRODUCT DESCRIPTION

copper tungsten plate Introduction:

We manufacture high-quality copper tungsten plates (CuW) using advanced powder metallurgy techniques. Our plates offer a unique combination of excellent electrical and thermal conductivity, high strength, and exceptional wear resistance. We produce CuW plates with varying copper and tungsten ratios to meet specific application requirements. Our plates are available in a range of sizes and thicknesses, and we can also provide custom solutions based on your specifications.

Product Parameters

General Specifications

| Property | Value |

|---|---|

| Thickness Range | 1 mm - 50 mm |

| Width Range | 10 mm - 500 mm |

| Length Range | 100 mm - 2000 mm |

| Density | 15.6 g/cm³ |

| Melting Point | 3000°C |

| Hardness | 2000 HV |

Chemical Composition

| Element | Content (%) |

|---|---|

| Copper (Cu) | 10 - 30 |

| Tungsten (W) | 70 - 90 |

| Iron (Fe) | ≤0.5 |

| Nickel (Ni) | ≤0.1 |

| Other Impurities | ≤0.2 |

Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength | 400 MPa |

| Tensile Strength | 500 MPa |

| Elongation | 1.5% |

| Thermal Conductivity | 150 W/m·K |

| Electrical Resistivity | 10 μΩ·cm |

|

|

Physical and Chemical Properties

Our copper tungsten plate exhibit several advantageous physical and chemical properties:

High Thermal Conductivity: Excellent heat dissipation makes them ideal for high-temperature applications.

High Electrical Conductivity: Suitable for electrical contacts and components.

Wear Resistance: Combines the hardness of tungsten with the ductility of copper to resist wear and abrasion.

Thermal Stability: Maintains performance in high-temperature environments.

|

|

Product Functions

Heat Dissipation: Our copper tungsten plate are excellent at transferring and dissipating heat, making them suitable for use in high-temperature environments.

Electrical Conductivity: The high electrical conductivity of copper combined with tungsten's durability ensures reliable performance in electrical applications.

Wear Resistance: The hardness of tungsten enhances the wear resistance of the plates, extending their lifespan in abrasive environments.

Thermal Stability: They maintain structural integrity and performance under extreme thermal conditions.

Product Applications

Aerospace Industry: Used in rocket nozzles and other high-temperature components where both high thermal conductivity and wear resistance are crucial.

Electronics: Ideal for electrical contacts, heat sinks, and other components that require high thermal and electrical conductivity.

Manufacturing: Utilized in high-wear applications such as machining and welding due to their superior hardness and durability.

Medical Devices: Applied in medical equipment where heat and electrical conductivity are essential for proper functioning.

|

|

Manufacturing Process and Production Flow

Powder Metallurgy: The process begins with mixing copper and tungsten powders, which are then compressed into desired shapes.

Sintering: The compressed shapes are sintered in a high-temperature furnace to form solid copper tungsten plate.

Machining: The sintered plates are cut, milled, and finished to precise specifications.

Inspection: Rigorous quality control ensures that each plate meets our high standards for physical and chemical properties.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates advanced production facilities, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, and precision machining equipment. Our factory is equipped with the latest technology to ensure that every one is manufactured to the highest standards of quality and precision.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

Wooden Crates: Provides robust protection for the plates during transportation.

Carton Boxes: Suitable for smaller quantities and easier handling.

Foam Padding: Prevents damage during shipping by cushioning the plates.

Waterproof Packaging: Ensures protection against moisture.

Custom Packaging: Tailored to specific customer requirements and international standards.

Logistics

Sea Freight: Cost-effective for large shipments and international orders.

Air Freight: Faster delivery for urgent orders.

Land Transport: Reliable for regional deliveries.

Multimodal Transport: Combines various methods for efficient delivery.

Express Courier: For expedited and time-sensitive shipments.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Extensive Experience: Over a decade of expertise in the non-ferrous metal industry.

Advanced Technology: Utilization of cutting-edge equipment and manufacturing processes.

Global Reach: Products exported to major markets worldwide, including the US, Europe, and Asia.

High-Quality Standards: Commitment to delivering products that meet the highest industry standards.

Customer-Centric Approach: Dedicated to providing excellent service and tailored solutions.

|

|

OEM/ODM Services

We offer comprehensive OEM and ODM services to meet specific requirements for High-Temperature Tungsten Plate. Our team works closely with clients to provide customized solutions that fit their unique needs.

|

|

FAQs

What thickness options are available for our products?

We offer plates ranging from 1 mm to 50 mm in thickness.

Can you provide custom sizes and shapes?

Yes, we can customize sizes and shapes according to your specifications.

What is the typical lead time for orders?

Lead time varies depending on order size and customization, generally ranging from 2 to 4 weeks.

How are the products packaged?

Our plates are packaged in wooden crates, carton boxes, with foam padding and waterproof materials to ensure safe delivery.

Do you provide samples for evaluation?

Yes, we offer samples for assessment before placing a full order.

Contact us

For more information about our copper tungsten plate or to discuss your specific needs, please contact us at info@peakrisemetal.com. Our team is here to assist you and provide the best solutions for your requirements. Partner with Shaanxi Peakrise Metal Co., Ltd. for high-quality tungsten plates and exceptional service.