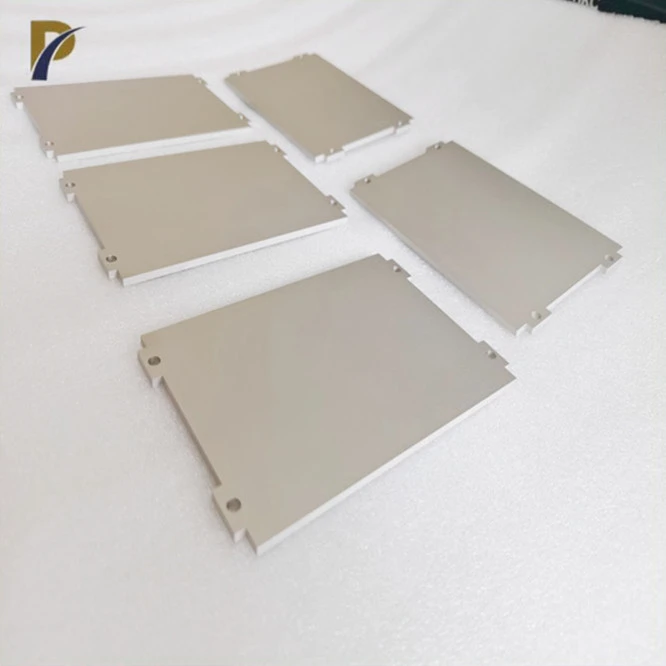

molybdenum copper alloy heat sink

Thickness: 0.5~20mm

Width: 50~100mm

Length: 100~200mm

Density: 9.64~9.98g/cm3

Thermal Conductivity: 160~280 W/M·K

Conductivity: 0.034~0.05 μΩm

Plating: Nickel Or Silver

Shape: sheet,plate

Application: machinery, electricity, electronics, electric vehicles, metallurgy and other industries.

PRODUCT DESCRIPTION

Product Introduction:molybdenum copper alloy heat sink

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of advanced molybdenum copper alloy heat sinks. As a leading producer in the field of non-ferrous metals, we specialize in providing high-quality alloys tailored for heat dissipation applications. Our products combine the excellent thermal conductivity of copper with the robustness of molybdenum, making them ideal for demanding thermal management solutions in various industries.

Product Specifications

| Property | Value |

|---|---|

| Copper Content | 60-90% |

| Molybdenum Content | 10-40% |

| Density | 9.8 - 10.2 g/cm³ |

| Thermal Conductivity | 140-190 W/m·K |

| Coefficient of Thermal Expansion | 7.3-9.0 × 10^-6 /K |

|

|

Physical and Chemical Properties

Our Copper Molybdenum Heat Sink are famous for their remarkable warm conductivity, negligible warm extension, and sublime machinability. They are ideal for applications that require precise thermal management and efficient heat dissipation because of these properties.

Our heat sinks are built to withstand harsh operating conditions and have strong resistance to oxidation and corrosion, ensuring long-term performance and reliability. Whether in aviation, hardware, or media communications, where warm administration is basic, our Molybdenum Copper Heat Sink give a solid arrangement.

|

|

Molybdenum Copper Alloy Heat Sink Features

- High Thermal Conductivity: Efficiently transfers heat away from sensitive components.

- Low Thermal Expansion: Minimizes the risk of thermal stress and cracking.

- Corrosion Resistance: Ensures durability in challenging environments.

- Customizable Shapes and Sizes: Tailored to meet specific customer requirements.

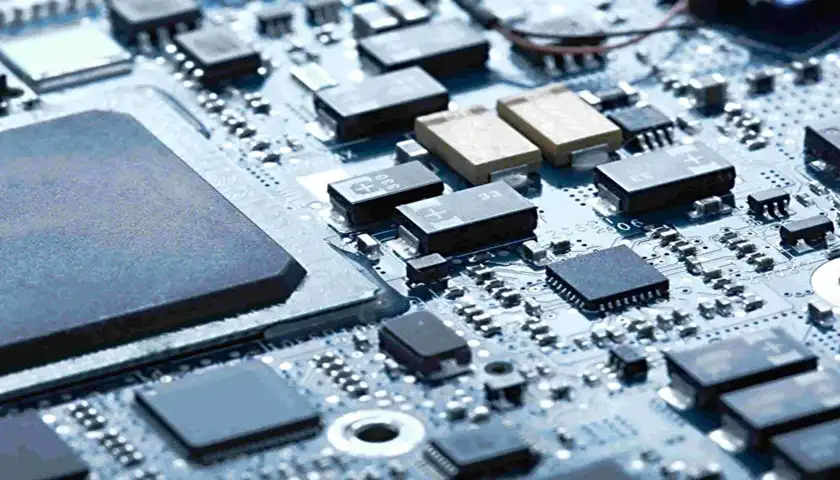

Applications

Our molybdenum copper alloy heat sinks find diverse applications:

- Electronics: Optoelectronic devices, power modules, LED assemblies.

- Aerospace: Satellite components, thermal shields.

- Medical: Laser systems, high-power electronic equipment.

- Industrial: Semiconductor processing, high-frequency communication devices.

|

|

Production Process

Our state-of-the-art manufacturing facilities at Shaanxi Peakrise Metal Co., Ltd. are outfitted with cutting-edge technology, such as vacuum arc melting furnaces, intermediate frequency sintering furnaces, and precision machining equipment. These high level capacities permit us to deliver many top notch items custom-made to meet the demanding prerequisites of our worldwide customer base.

Because they provide precise control over the conditions for heating and sintering, our intermediate frequency sintering furnaces are an essential part of our production process. This guarantees consistency in material properties and improves the presentation attributes of our items, for example, tungsten amalgams and tantalum parts.

|

|

|

Why Choose Us?

- Extensive Industry Experience: Over a decade of excellence in non-ferrous metal production.

- Global Reach: Established partnerships across Taiwan, Ukraine, South Korea, USA, and more.

- Customization Capabilities: Dedicated to meeting unique client requirements with precision.

- Quality Assurance: Commitment to delivering superior products through continuous R&D and stringent quality controls.

|

OEM Services

We offer comprehensive OEM services, collaborating closely with clients to develop customized solutions that meet exacting standards and specifications.

|

|

FAQ

-

What are the typical sizes available for molybdenum copper alloy heat sink?

- Sizes range from small components to large-scale assemblies, tailored to application needs.

-

How can molybdenum copper alloy benefit electronic applications?

- It enhances thermal management in high-power devices, prolonging operational lifespan.

-

What certifications do your products hold?

- Our alloys meet ISO 9001 standards for quality management.

-

Can you provide material traceability documentation?

- Yes, we ensure full traceability of materials used in our alloys.

-

What is the typical lead time for orders?

- Lead times vary based on order size and customization requirements.

Packaging

- Wooden Crates: For robust protection during long-distance transportation.

- Cardboard Boxes: Cost-effective packaging for smaller orders.

- Customized Packaging: Tailored to specific product dimensions and shipping requirements.

Logistics

- Sea Freight: Economical for large shipments.

- Air Freight: Rapid delivery for urgent orders.

- Land Transportation: Efficient for regional distribution.

- Multimodal Transport: Integrated solutions for complex logistical needs.

- Express Services: Quick turnaround for small, time-sensitive shipments.

|

|

|

|

|

|

|

|

|

|

Contact Us

Ready to enhance your thermal management solutions? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com to discuss your requirements and explore how our molybdenum copper alloy heat sinks can benefit your projects.