tungsten molybdenum alloy

W Content: 50% (wt%)

Mo Content: 50% (wt%)

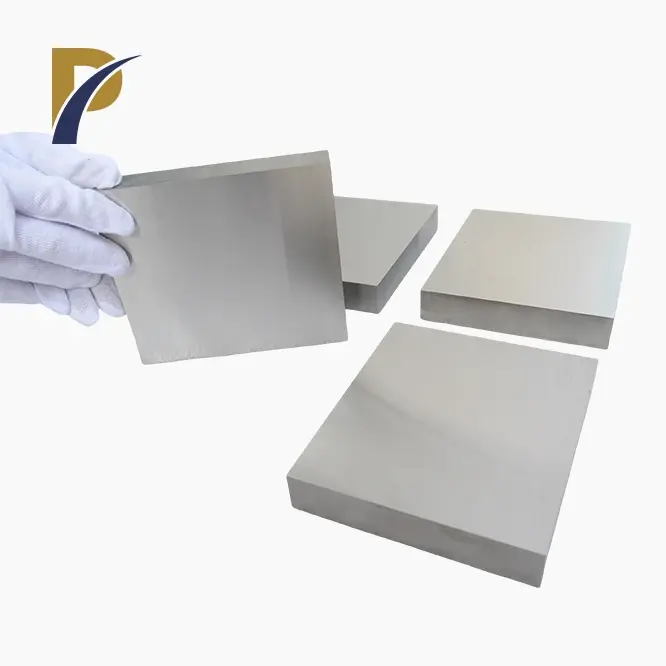

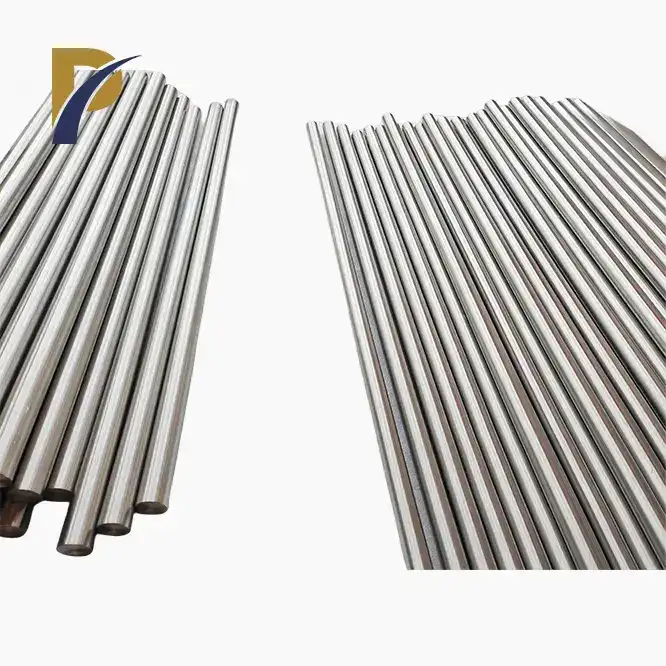

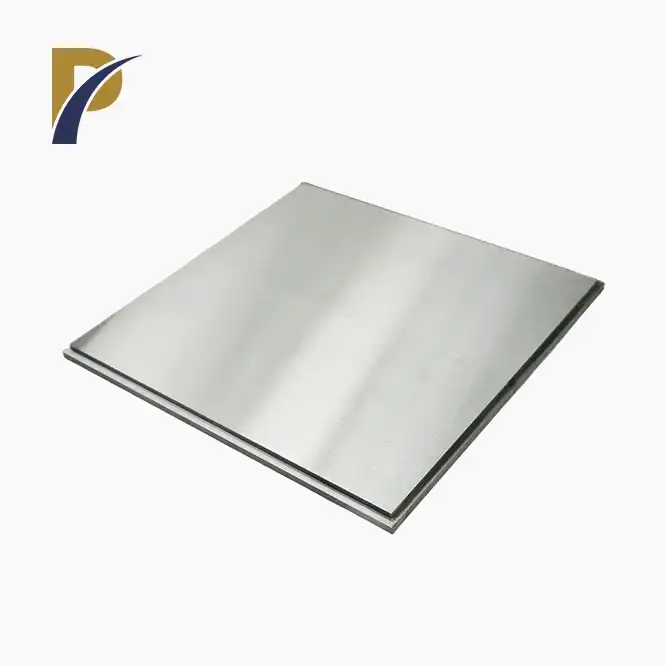

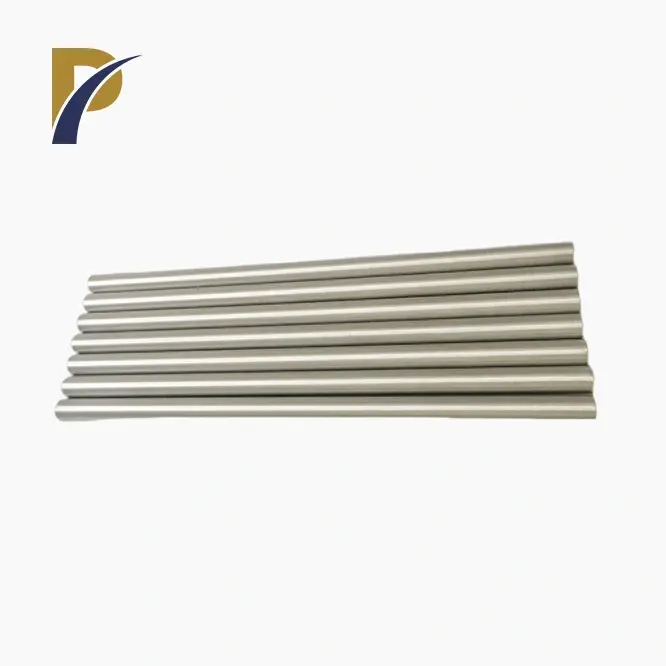

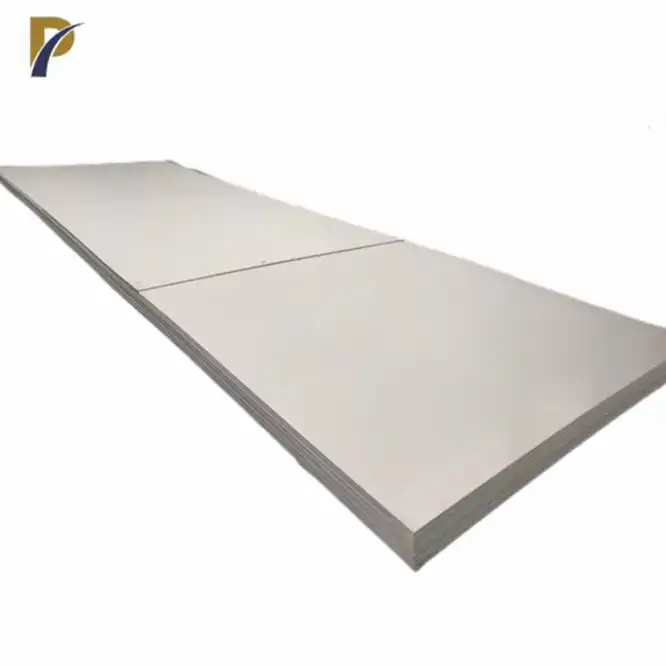

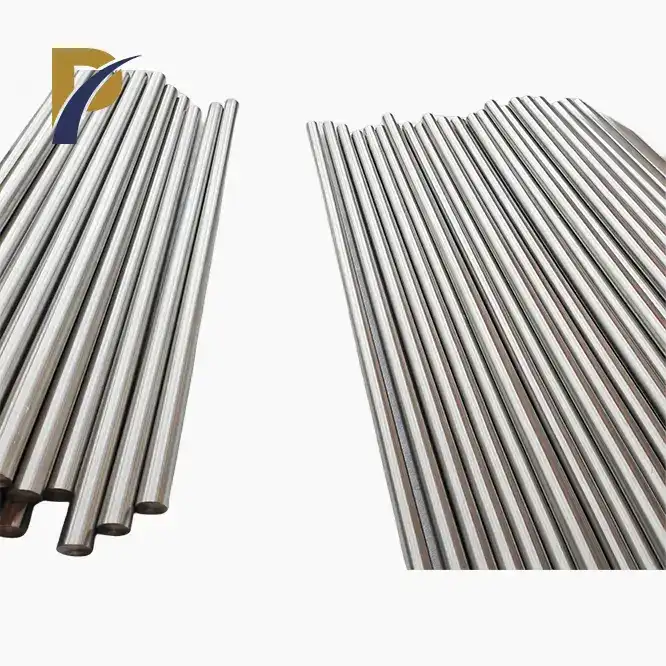

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction:tungsten molybdenum alloy

At Shaanxi Peakrise Metal Co., Ltd., we are focused on conveying top-quality tungsten-molybdenum alloy items that satisfy the most elevated industry guidelines. Our products joins the extraordinary properties of tungsten and molybdenum to make a material with unmatched execution in outrageous circumstances. This alloy is explicitly designed to give improved strength, sturdiness, and warm security, settling on it a favored decision for different cutting edge applications.

Molybdenum Tungsten Alloy, which ordinarily comprises of 90% tungsten and 10% molybdenum, is famous for its amazing high-temperature opposition and mechanical properties. The alloy succeeds in conditions that request vigor and dependability, like aviation, hardware, and modern cycles. As a main provider, Peakrise Metal guarantees that every item is produced with accuracy and care, offering our clients a reliable answer for their most difficult applications.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Tungsten-Molybdenum Alloy |

| Tungsten Content | 90% |

| Molybdenum Content | 10% |

| Density | 19.3 g/cm³ |

| Melting Point | 2900°C |

| Thermal Conductivity | 155 W/m·K |

| Tensile Strength | 550 MPa |

| Hardness | 250 HV |

| Young's Modulus | 410 GPa |

|

|

|

Physical and Chemical Properties

Density: 19.3 g/cm³

Melting Point: 2900°C

Thermal Conductivity: 155 W/m·K

Tensile Strength: 550 MPa

Hardness: 250 HV

Young's Modulus: 410 GPa

These properties ensure that the product is ideal for applications requiring superior strength and resistance to extreme temperatures.

|

|

Tungsten Molybdenum Alloy Functions

High-Temperature Resistance: The alloy maintains its strength and structural integrity even at temperatures up to 2900°C, making it suitable for high-temperature environments.

Enhanced Mechanical Strength: With a tensile strength of 550 MPa, the alloy offers exceptional durability and resistance to deformation under stress.

Excellent Thermal Conductivity: The high thermal conductivity (155 W/m·K) allows for efficient heat transfer, which is crucial in many industrial processes.

Superior Hardness: The tungsten molybdenum alloy’s hardness of 250 HV contributes to its resistance to wear and abrasion, ensuring longevity in demanding applications.

Product Applications

Aerospace Industry: It is used in components such as rocket nozzles, heat shields, and high-performance bearings, where high-temperature and high-stress conditions are common.

Electronics Manufacturing: The alloy’s thermal and mechanical properties make it ideal for use in sputtering targets, filament supports, and other components in electronic devices.

Industrial Equipment: The alloy is employed in high-temperature furnaces, cutting tools, and other equipment that require materials with exceptional strength and heat resistance.

Research and Development: Its performance under extreme conditions makes tungsten-molybdenum alloy a valuable material for experimental setups and high-precision applications.

|

|

Production Process

Material Preparation: Tungsten and molybdenum powders are mixed in precise proportions.

Alloying: The mixture is subjected to high temperatures in a vacuum furnace to form a homogeneous alloy.

Machining: The Molybdenum Tungsten Alloy is processed into the desired shape using advanced machining techniques.

Quality Control: Each product undergoes rigorous testing to ensure it meets the required specifications and performance standards.

|

|

|

Company Overview

Shaanxi Peakrise Metal Co., Ltd. is a recognized maker of non-ferrous metals and alloys with broad involvement with tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Starting around 2010, we have zeroed in on sending out top notch metal items to global business sectors, laying down a good foundation for ourselves as a main provider in the business. Our cutting edge offices are outfitted with cutting edge creation innovation, empowering us to convey items that satisfy the most noteworthy guidelines of value and execution.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

Wooden Crates: Secure and durable packaging for heavy and large orders.

Cardboard Boxes: Ideal for smaller quantities, offering lightweight protection.

Foam Padding: Additional cushioning to prevent damage during transit.

Waterproof and Moisture-Proof Packaging: Protects against environmental factors.

Custom Packaging: Tailored solutions based on customer needs.

International Standards: All packaging complies with global shipping requirements.

Logistics

Sea Freight: Cost-effective option for large volumes and long-distance shipping.

Air Freight: Fast delivery for urgent or high-value orders.

Land Transport: Efficient for regional distribution.

Multimodal Transport: Combines different transport methods for optimized logistics.

Courier Services: Expedited shipping for smaller or urgent deliveries.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Experienced Team: Over a decade of experience in producing and supplying non-ferrous metal products.

Quality Assurance: Advanced technology and stringent quality control processes.

Global Reach: Established relationships with clients across various countries.

State-of-the-Art Facilities: Cutting-edge equipment for precise and efficient manufacturing.

Customer Focused: Customizable solutions and dedicated customer support.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers thorough OEM and ODM administrations, permitting clients to modify items to their particular requirements. We give fitted answers for meet definite details and prerequisites, guaranteeing the greatest and execution.

|

|

FAQ

What is tungsten-molybdenum alloy? Tungsten-molybdenum alloy is a high-performance material combining tungsten and molybdenum to offer superior strength, thermal stability, and mechanical properties.

What are the typical applications of this alloy? The tungsten molybdenum alloy is used in aerospace, electronics, industrial equipment, and research applications where high temperature and stress resistance are required.

What is the melting point of tungsten-molybdenum alloy? The alloy has a melting point of 2900°C, making it suitable for extremely high-temperature environments.

Can the alloy be customized for specific applications? Yes, we offer OEM and ODM services to customize the alloy according to your specific needs and requirements.

How do you ensure the quality of your products? We use advanced manufacturing technology and conduct rigorous quality control to ensure all products meet high standards of performance and reliability.

Contact Us

For premium tungsten-molybdenum alloy products and exceptional service, reach out to Shaanxi Peakrise Metal Co., Ltd. We are here to meet your high-performance material needs and provide tailored solutions for your industry. Contact us at info@peakrisemetal.com to discuss your requirements and place your order.