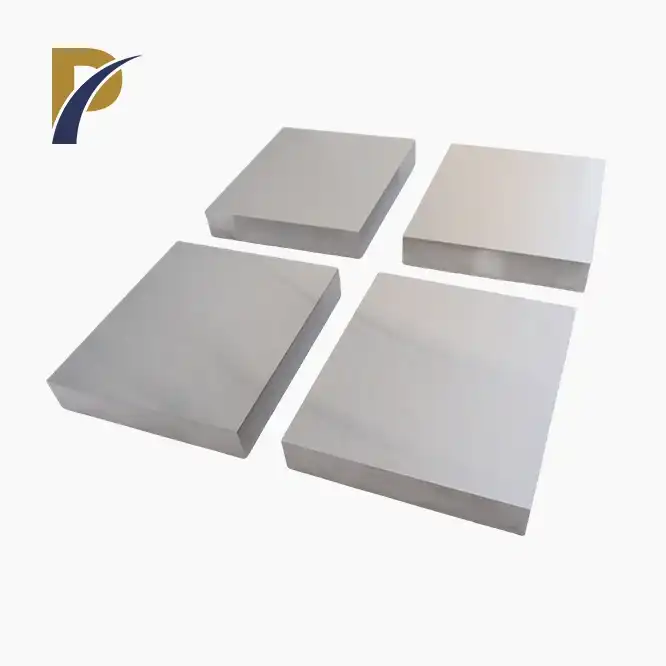

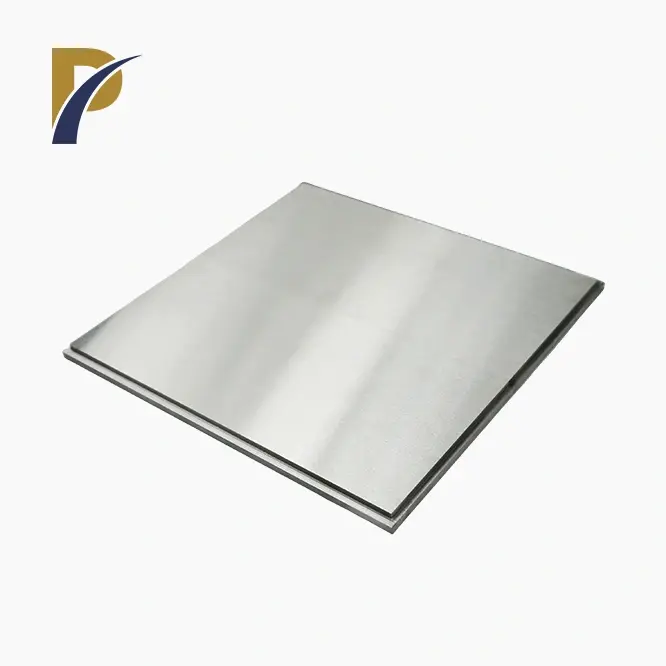

tungsten and molybdenum alloy plate

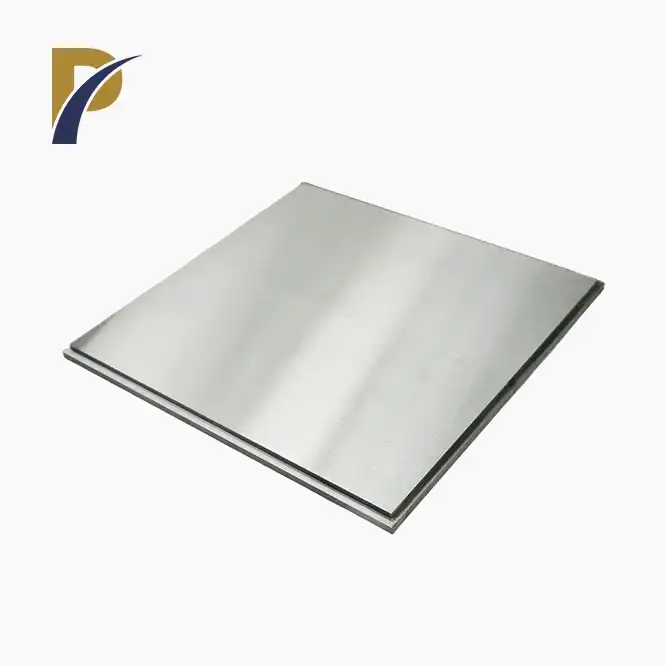

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Tickness: 0.3-25mm

Width: 50-600mm

Length: <2500mm

Shape: Plate,Custom Parts

Advantage: High Strength

Standard: ASTM B386

Surface: Polished, Alkaline, Washing Sandblasting

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction: tungsten and molybdenum alloy plate

Shaanxi Peakrise Metal Co., Ltd. gladly presents our top notch tungsten and molybdenum alloy plate, intended for applications requiring prevalent strength, warm obstruction, and dependability. Consolidating the momentous properties of tungsten and molybdenum, these alloy plates offer an uncommon harmony between strength and sturdiness, making them ideal for different demanding enterprises.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Tungsten-Molybdenum Alloy |

| Tungsten Content | 90% |

| Molybdenum Content | 10% |

| Density | 19.3 g/cm³ |

| Melting Point | 2900°C |

| Thermal Conductivity | 155 W/m·K |

| Tensile Strength | 550 MPa |

| Hardness | 250 HV |

| Young's Modulus | 410 GPa |

| Thickness Range | 1 mm to 100 mm |

| Plate Size | Customizable |

|

|

Physical and Chemical Properties

Density: 19.3 g/cm³

Melting Point: 2900°C

Thermal Conductivity: 155 W/m·K

Tensile Strength: 550 MPa

Hardness: 250 HV

Young's Modulus: 410 GPa

|

|

Tungsten and Molybdenum Alloy Plate Functions

Exceptional High-Temperature Resistance: The alloy's melting point of 2900°C ensures it performs reliably in high-temperature environments, maintaining structural integrity and performance.

High Mechanical Strength: With a tensile strength of 550 MPa, the plates exhibit excellent resistance to deformation and wear, making them suitable for high-stress applications.

Effective Thermal Conductivity: The alloy's thermal conductivity of 155 W/m·K facilitates efficient heat dissipation, which is critical for components in high-temperature processes.

Superior Hardness: The hardness rating of 250 HV contributes to the material's durability, making it resistant to abrasion and surface wear.

Product Applications

Aerospace Industry: Tungsten-molybdenum alloy plates are used in critical aerospace components, such as heat shields, rocket nozzles, and other high-temperature applications where material reliability is essential.

Electronics Manufacturing: The alloy plates are employed in electronic devices as sputtering targets, heat sinks, and other components that require excellent thermal and mechanical properties.

Industrial Equipment: The plates find applications in high-temperature furnaces, cutting tools, and other machinery that operates under extreme conditions.

Research and Development: These alloy plates are utilized in experimental setups and high-precision applications where their unique properties can be fully leveraged.

|

|

Production Process

Material Preparation: Tungsten and molybdenum powders are mixed in precise proportions according to the desired alloy composition.

Alloying: The mixture is processed in a vacuum furnace at high temperatures to create a homogeneous alloy.

Plate Formation: The alloy is then rolled or pressed into plates of various thicknesses and sizes.

Machining and Finishing: Plates are machined to meet specific dimensions and surface finish requirements.

Quality Assurance: Each plate undergoes rigorous testing and inspection to ensure it meets the highest standards of quality and performance.

|

|

|

Company Overview

Shaanxi Peakrise Metal Co., Ltd. is a main maker of non-ferrous metals and alloys, with broad mastery in tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Starting around 2010, we have zeroed in on expanding our commodity business, giving top notch metal items to worldwide business sectors. Our best in class creation offices and obligation to greatness have laid out us as a confided in provider in the business.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

Wooden Crates: Ideal for large and heavy plates, ensuring secure transport.

Cardboard Boxes: Suitable for smaller quantities, offering protection and ease of handling.

Custom Packaging: Tailored solutions based on customer requirements.

International Standards: All packaging complies with global shipping and handling standards.

Logistics

Sea Freight: Economical option for bulk orders and international shipping.

Air Freight: Fast delivery for urgent orders and high-value items.

Land Transport: Efficient for regional distribution and short distances.

Multimodal Transport: Combines different transport methods for optimized logistics.

Courier Services: Expedited shipping for smaller or urgent deliveries.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Expertise and Experience: Over a decade of experience in producing and supplying high-quality non-ferrous metals.

State-of-the-Art Facilities: Advanced production technology ensuring precise and efficient manufacturing.

Global Reach: Established relationships with customers worldwide and a reputation for reliability.

Comprehensive Quality Control: Rigorous testing and quality assurance processes to meet the highest standards.

Customer-Centric Approach: Flexible solutions and dedicated support to meet diverse customer needs.

|

|

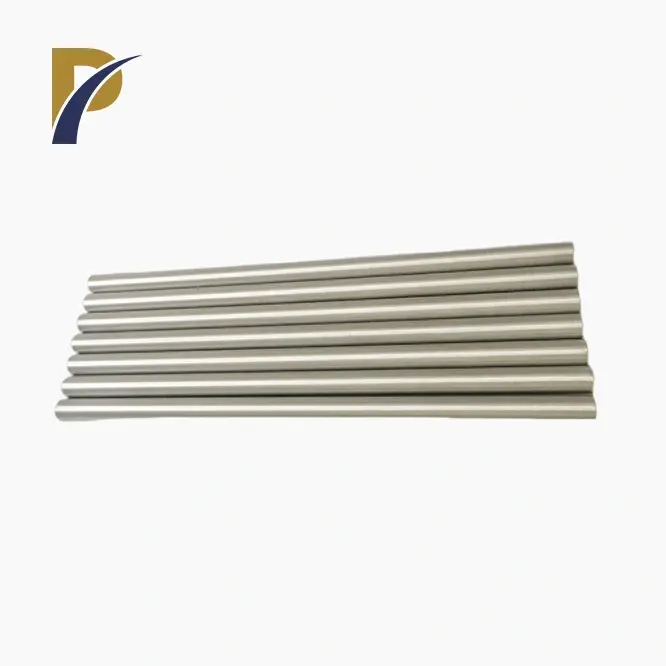

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers exhaustive OEM and ODM administrations, taking into consideration modified creation of tungsten and molybdenum alloy plate. Our group works intimately with clients to meet explicit necessities and convey custom fitted arrangements that upgrade execution and fulfill industry guidelines.

|

|

FAQ

What is tungsten and molybdenum alloy plate? Tungsten and molybdenum alloy plates are high-performance materials made from a blend of tungsten and molybdenum, designed for applications requiring high strength, thermal resistance, and durability.

What are the typical uses of tungsten-molybdenum alloy plates? These plates are used in aerospace, electronics, industrial equipment, and research applications where high-temperature resistance and mechanical strength are needed.

What thicknesses and sizes are available? Our plates are available in a range of thicknesses from 1 mm to 100 mm and can be customized to specific sizes based on customer requirements.

Can I get customized plates for specific applications? Yes, we offer OEM and ODM services to produce customized plates tailored to your specific needs and application requirements.

Contact Us

For premium tungsten and molybdenum alloy plate and unparalleled service, reach out to Shaanxi Peakrise Metal Co., Ltd. We are committed to providing high-quality materials and solutions tailored to your needs. Contact us today at info@peakrisemetal.com to discuss your requirements and place your order.