tungsten electrodes

Material: Pure Tungsten

Purity: 99.95%

Diameter: 0.1~10mm

Length: 20~200mm

Surface: Polished

Melting Point : 3422℃

Application: Argon Arc Welding,TIG Welding,plasma Cutting,High Frequency Surgical Ablation Electrodes

PRODUCT DESCRIPTION

Tungsten electrodes Product Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of high-quality tungsten electrodes. Armed with a vast array of years of expertise in the non-ferrous metal sector, our company stands as a beacon of professionalism, specializing in crafting products that not only meet but exceed the pinnacle of performance and reliability standards.

Product Parameters

| Parameter | Details |

|---|---|

| Material | Pure Tungsten (W) or Tungsten Alloys |

| Purity | Pure Tungsten: ≥ 99.95%, Alloy: Customizable |

| Density | 19.3 g/cm³ (Pure Tungsten) |

| Melting Point | 3422°C (6192°F) |

| Electrical Conductivity | High electrical conductivity |

| Thermal Conductivity | 173 W/m·K |

| Diameter | Customizable (e.g., 1.0mm, 1.6mm, 2.4mm, 3.2mm) |

| Length | Standard lengths: 150mm, 175mm, 178mm, Custom lengths available |

| Surface Finish | Ground, Polished, or Oxidized |

| Tip Type | Pointed, Rounded, or Customized |

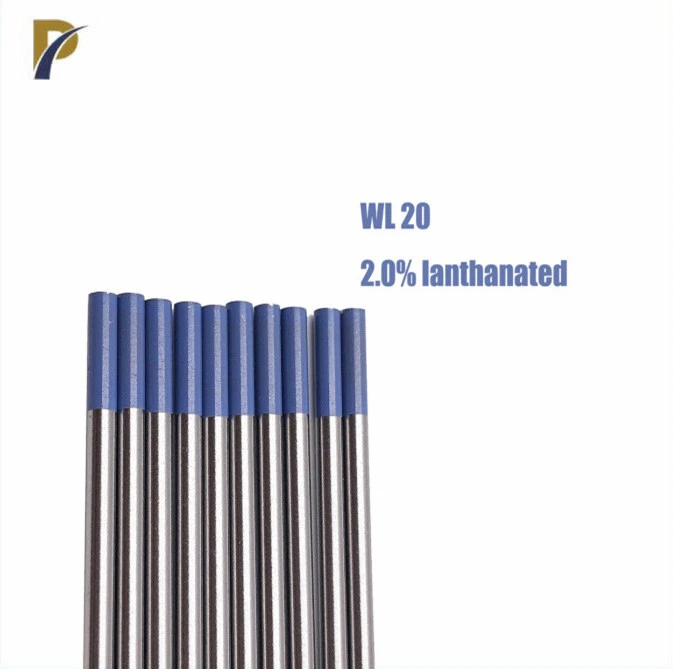

| Electrode Type | Pure Tungsten, Thoriated (WT20), Ceriated (WC20), Lanthanated (WL20), Zirconiated (WZ8) |

| Arc Stability | Excellent arc stability in AC/DC welding |

| Hardness | 350 HV (Vickers Hardness) |

| Applications | TIG (GTAW) Welding, Plasma Welding, Electrochemical machining, Electrical discharge machining (EDM) |

| Oxidation Resistance | High resistance to oxidation at elevated temperatures |

| Packaging | Packed in plastic tubes or boxes with protective end caps |

| Customization | Available for specific alloy compositions, lengths, and tips |

|

|

|

|

Product Applications

Tungsten electrodes are essential components in various industrial applications due to their high melting point, excellent electrical conductivity, and remarkable durability. Their primary uses include:

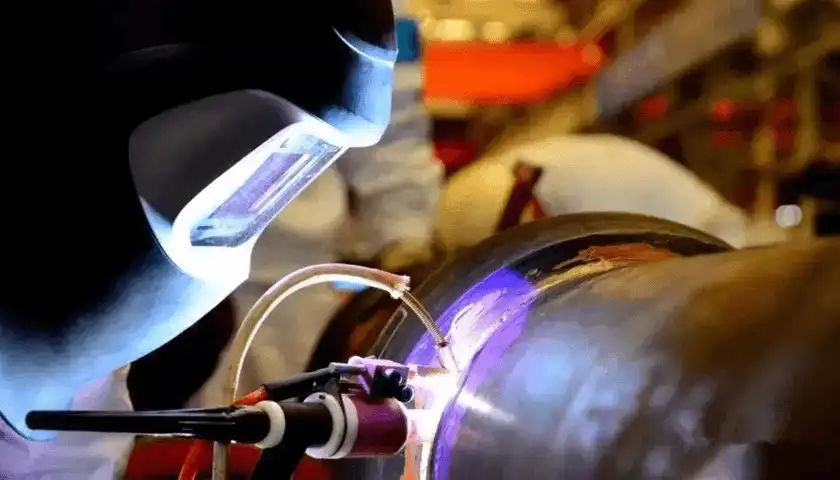

TIG (GTAW) Welding: Tungsten electrodes are widely used in Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW). They provide a stable arc, allowing for precise and clean welds in materials such as stainless steel, aluminum, and titanium. Different types of tungsten electrode (e.g., pure, thoriated, ceriated, lanthanated, and zirconiated) are selected based on the specific welding requirements.

Plasma Welding and Cutting: Tungsten electrodes are also utilized in plasma welding and cutting processes, where they serve as the cathode to produce a high-temperature plasma arc. This arc is capable of cutting through various metals with precision and efficiency.

Electrochemical Machining (ECM): In electrochemical machining, tungsten are used as tools to remove metal from workpieces with high precision. Their resistance to wear and corrosion makes them ideal for this non-contact machining process, often applied in the aerospace and medical device industries.

Electrical Discharge Machining (EDM): Tungsten are used in EDM for machining hard metals and alloys. The electrodes help create intricate shapes and fine details by discharging electrical sparks to erode the material.

High-Temperature Applications: Due to their ability to withstand extremely high temperatures without deformation, tungsten are used in various high-temperature applications, such as in the aerospace industry for rocket engine components and in the electronics industry for high-power semiconductors.

Lighting and Electronics: Tungsten electrodes are used in lighting applications, including in gas discharge lamps and fluorescent lamps, where they help maintain a stable electrical arc. They are also used in electronics for manufacturing components like vacuum tubes and x-ray tubes.

|

|

Production Process

At Shaanxi Peakrise Metal Co., Ltd., our tungsten electrodes are manufactured using advanced processes including vacuum annealing and precision grinding to meet exacting specifications.

|

|

|

Our Factory

Equipped with cutting-edge facilities, including advanced vacuum arc melting furnaces and precision CNC machinery, we meticulously ensure quality at every pivotal stage of the production process. These state-of-the-art tools enable us to maintain stringent control over material purity, dimensional accuracy, and surface finish, ensuring that every product meets or exceeds industry standards. Our commitment to leveraging the latest technology ensures a seamless, efficient, and highly precise manufacturing experience, thereby delivering unparalleled quality to our clients at every turn.

Outfitted with cutting-edge technologies, including sophisticated vacuum arc melting furnaces and precision-driven CNC machinery, our company meticulously guarantees quality excellence at every pivotal juncture of the production process. This formidable combination of technological prowess and manufacturing might underscores our unwavering dedication to crafting products that embody the pinnacle of industry standards, a testament to our relentless pursuit of innovation and perfection.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging&Logistics

We offer flexible shipping options:

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. supports customized manufacturing Tungsten Electrodes' processes to meet unique customer demands.

|

|

Frequently Asked Questions (FAQ)

What is the typical shelf life of Pure Tungsten Electrodes?

Our electrodes have an indefinite shelf life if stored properly.

Can Tungsten Electrode be used for both AC and DC welding?

Yes, they are versatile and suitable for both types of welding currents.

Do you offer bulk discounts for large orders?

Yes, we provide competitive pricing based on order volumes.

Are your products compliant with international safety standards?

Absolutely, all our Tungsten Electrode meet stringent quality and safety regulations.

How can I place an order for custom specifications?

Please contact our sales team at info@peakrisemetal.com for personalized assistance.

Contact us

Contact us today to discuss how Shaanxi Peakrise Metal Co., Ltd. can fulfill your Pure Tungsten Electrodes requirements. Email us at info@peakrisemetal.com for inquiries or to place an order.