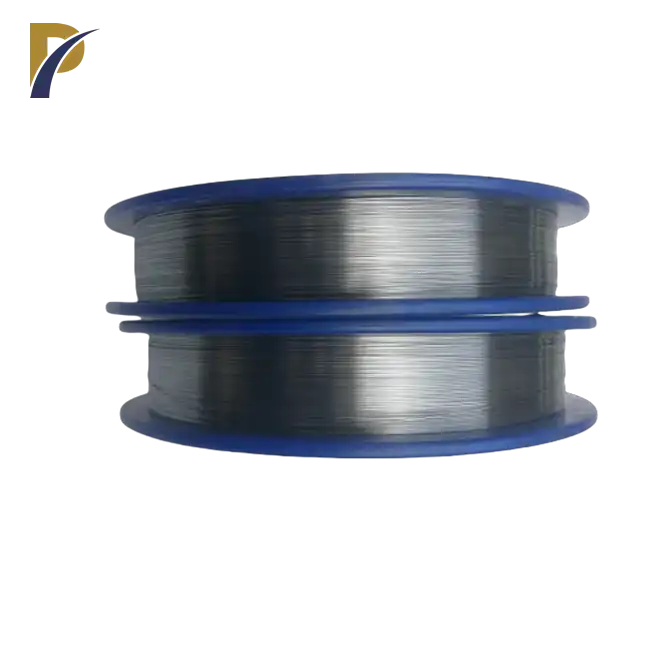

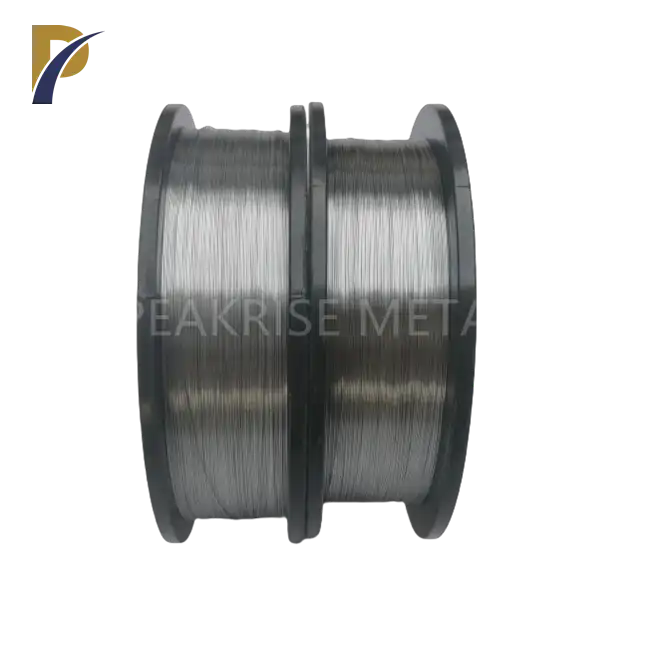

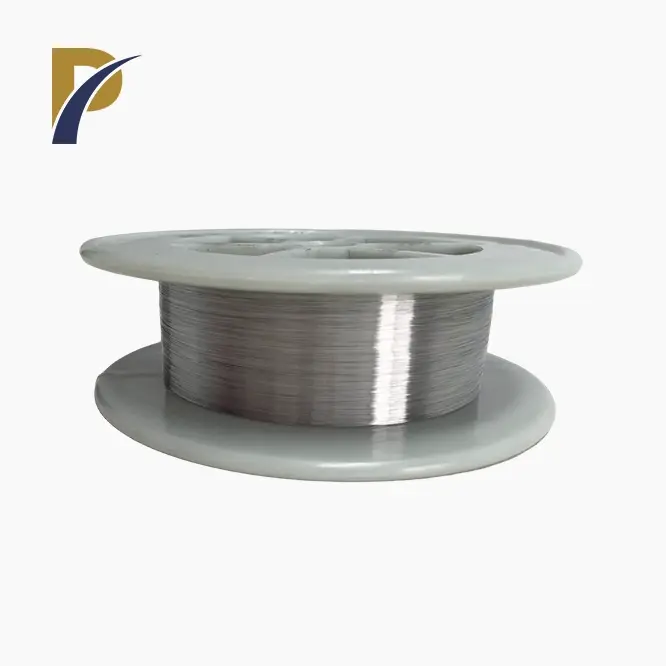

molybdenum wires

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Molybdenum Wires Introduction

We are a leading manufacturer of high-quality molybdenum wires. Our wires are made from pure molybdenum, offering excellent properties for various industrial applications. We produce wires in a range of diameters and lengths to meet specific customer needs. Our commitment to quality and customer satisfaction makes us a preferred supplier for businesses worldwide. We provide consistent quality, reliable delivery, and competitive pricing.

Product Specifications

| Property | Value |

|---|---|

| Diameter Range | 0.02 mm - 3.0 mm |

| Purity | 99.95% min |

| Tensile Strength | 600 - 1000 MPa |

| Elongation | 3% - 5% |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Surface Condition | Clean, free of defects |

| Electrical Conductivity | 31.2 μΩ·cm |

| Thermal Conductivity | 138 W/m·K |

|

|

Physical and Chemical Properties

Products exhibit remarkable resistance to corrosion and oxidation, ensuring longevity and reliability in extreme environments. They are characterized by high thermal stability and low coefficient of thermal expansion, making them ideal for applications requiring consistent performance under challenging conditions.

Molybdenum wires are renowned for their exceptional physical and chemical properties that make them suitable for a variety of high-performance applications. Molybdenum, with an atomic number of 42 and the symbol Mo, is a transition metal characterized by its high melting point, which is among the highest of all readily available metals, second only to tungsten and tantalum 1. This property is particularly beneficial for applications that require materials to withstand extreme temperatures, such as in high-temperature furnaces and incandescent lamp filaments.

High-Temperature Molybdenum Wires also have a low thermal expansion and high heat conductivity, making them suitable for use in electrically-heated glass furnaces and as electrodes 3. Additionally, molybdenum sulfide, a compound of molybdenum, is used as a high-temperature lubricant due to its ability to perform well under conditions where oils would decompose

|

|

Molybdenum Wires Features

- High Temperature Resistance: molybdenum wires maintains strength and integrity at temperatures exceeding 2000°C.

- Superior Electrical Conductivity: Ensures efficient electrical transmission in specialized applications.

- Excellent Machinability: Allows for precise shaping and customization.

- Low Thermal Expansion: Minimizes deformation under thermal stress.

- High Purity: Meets stringent industry standards for reliability and performance consistency.

Product Applications

- Heating Elements: Used in high-temperature furnaces and electrical discharge machining (EDM).

- Wire EDM Cutting: Provides precise cutting in manufacturing processes.

- Glass Industry: Supports glass-to-metal sealing processes.

- Aerospace and Defense: Critical in missile and aircraft components.

- Electronics: Essential for semiconductor manufacturing.

|

|

Production Process and Technology

At Shaanxi Peakrise Metal Co., Ltd., molybdenum wires are manufactured using advanced processes including vacuum annealing, wire drawing, and precision machining. Our state-of-the-art facilities ensure strict adherence to quality standards, resulting in superior products trusted worldwide.

|

|

|

Our Manufacturing Facility

Equipped with cutting-edge technology such as vacuum arc melting furnaces, laser cutters, and CNC machines, our facility enables precise control over production processes. We emphasize continuous innovation and quality improvement to meet diverse customer needs.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Packaging: We offer wooden crates, cardboard boxes, and custom packaging solutions that meet international standards for protection against moisture and damage.

- Logistics: We provide sea freight, air freight, land transportation, multimodal transport, and expedited shipping services to ensure prompt delivery worldwide.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Shaanxi Peakrise Metal Co., Ltd. stands out due to:

- Extensive Industry Experience: Over a decade of expertise in non-ferrous metal production.

- Global Reach: Trusted supplier to clients in Taiwan, Ukraine, the USA, and beyond.

- Customization Capabilities: Tailored solutions to meet specific customer requirements.

- Commitment to Quality: Rigorous quality control processes ensuring superior products.

- Customer Focus: Dedicated to building long-term partnerships based on trust and reliability.

|

|

OEM Services

We offer comprehensive OEM services, collaborating closely with clients to develop customized product solutions that meet exact specifications and application requirements.

Frequently Asked Questions (FAQs)

-

What is the maximum operating temperature of products?

- products can withstand temperatures up to 2620°C without significant degradation.

-

Are products suitable for vacuum applications?

- Yes, their low outgassing characteristics make them ideal for vacuum environments.

-

Can you provide products with specific surface finishes?

- Absolutely, we offer various surface treatments tailored to application needs.

-

Do you offer certifications for your products?

- Yes, we provide certificates of compliance and material test reports upon request.

-

What is the typical lead time for orders?

- Lead times vary based on order volume and customization requirements. Contact us for detailed information.

|

|

Contact us

Contact Us Today! Explore the superior quality and reliability of our molybdenum wires. Partner with Shaanxi Peakrise Metal Co., Ltd. for your industrial metal needs. Reach out to us at info@peakrisemetal.com to discuss how we can support your projects globally.

YOU MAY LIKE

-

VIEW MOREmolybdenum wire drawing

VIEW MOREmolybdenum wire drawing -

VIEW MOREmolybdenum heater wire

VIEW MOREmolybdenum heater wire -

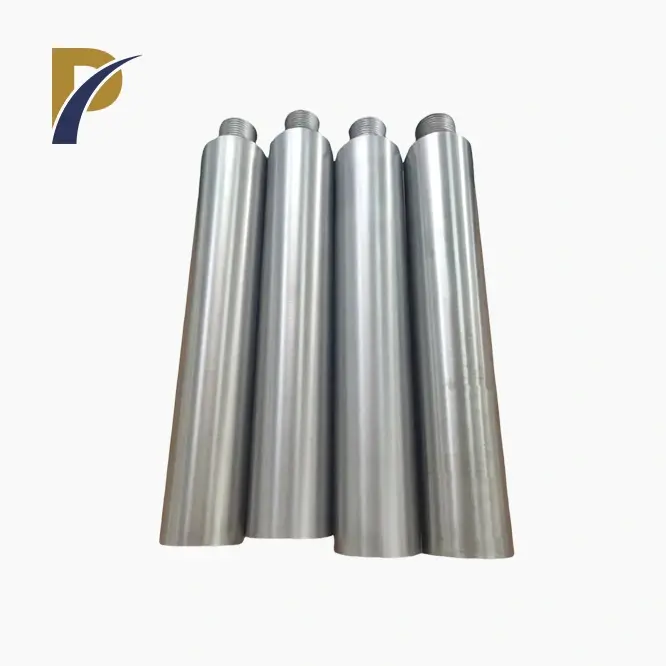

VIEW MORE50 diameter molybdenum elecrtode

VIEW MORE50 diameter molybdenum elecrtode -

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MOREzirconium 702 crucible

VIEW MOREzirconium 702 crucible -

VIEW MOREcustomized tantalum sputtering target

VIEW MOREcustomized tantalum sputtering target -

VIEW MORErolling molybdenum plate

VIEW MORErolling molybdenum plate -

VIEW MOREmolybdenum sintering boats

VIEW MOREmolybdenum sintering boats