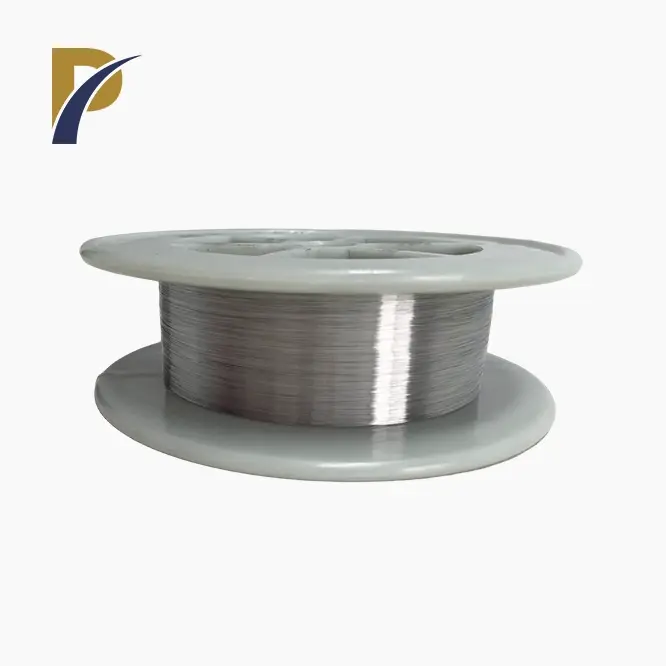

molybdenum heater wire

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Molybdenum Heater Wire Product Introduction

Introducing our premium molybdenum heater wire, an innovative solution for demanding heating applications. Molybdenum, an obstinate metal prestigious for its high dissolving point and superb electrical conductivity, shapes the center of these wires.Intended for outstanding strength and protection from outrageous temperatures, our product guarantees solid and effective intensity age in a large number of modern settings.

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of product, committed to providing high-quality products that meet the stringent demands of global customers. With years of experience in the production and processing of non-ferrous metals, we have established a reputation for excellence in both product quality and customer service. Our product is manufactured using advanced technologies and stringent quality control measures to ensure optimal performance and reliability in every application.

Product Specifications

| Parameter | Specification |

|---|---|

| Material Composition | ≥99.95% Molybdenum |

| Density | 10.2 g/cm³ |

| Melting Point | 2,623 °C |

| Tensile Strength | 700-800 MPa |

| Diameter Range | 0.1 mm to 3 mm |

| Operating Temperature | Up to 1,800 °C |

| Electrical Resistivity | 5.34 x 10⁻⁸ Ω·m |

|

|

Physical and Chemical Properties

Product is characterized by its high melting point, excellent thermal conductivity, low coefficient of thermal expansion, and good electrical conductivity. These properties make it suitable for high-temperature environments and applications where thermal and electrical stability are crucial.

- Melting Point: 2,623 °C

- Thermal Conductivity: 138 W/m·K

- Coefficient of Thermal Expansion: 4.8 x 10⁻⁶ /K

- Electrical Conductivity: 19.3 MS/m

|

|

Product Functions

- High-Temperature Performance: product maintains structural integrity and performance at temperatures up to 1,800 °C, making it ideal for high-temperature heating elements.

- Corrosion Resistance: It exhibits excellent resistance to oxidation and corrosion in harsh environments, ensuring long-term reliability.

- Thermal Efficiency: The superior thermal conductivity of molybdenum ensures efficient heat transfer, reducing energy consumption in heating applications.

- Durability: High tensile strength and resilience make it suitable for demanding industrial applications where mechanical stress is a factor.

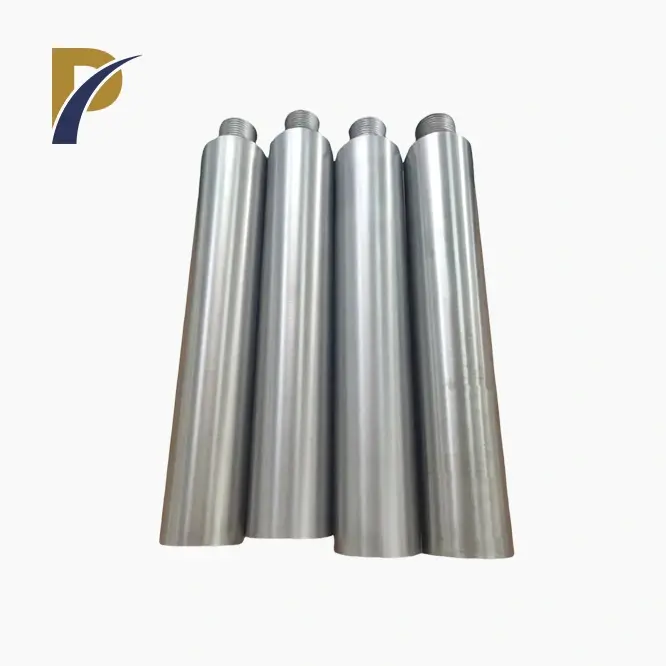

Product Applications

- Industrial Furnaces: Used as heating elements in vacuum and hydrogen furnaces due to its ability to withstand extreme temperatures.

- Aerospace: Integral in the manufacture of high-temperature components and heating elements in spacecraft and aircraft.

- Electronics: Essential for high-temperature electrical contacts and components in electronic devices.

- Glass Manufacturing: Used in the production of high-quality glass due to its high melting point and stability at elevated temperatures.

|

|

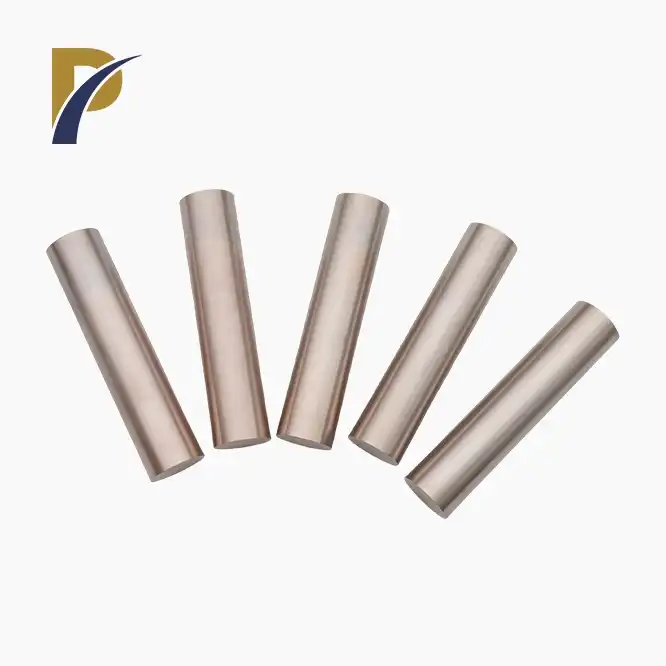

Manufacturing Process and Production Flow

The production of molybdenum heater wire involves several key steps to ensure the highest quality and performance:

- Material Selection: High-purity molybdenum raw materials are carefully selected.

- Melting and Alloying: The raw material is melted in a vacuum arc furnace to achieve the desired composition.

- Casting and Forming: The molten molybdenum is cast into ingots and then hot-rolled into rods.

- Drawing and Annealing: The rods are cold-drawn into wires of the required diameter, followed by annealing to relieve stress.

- Finishing and Inspection: The wires are polished, cut to size, and subjected to rigorous quality inspections to ensure compliance with specifications.

|

|

|

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is a carefully prepared producer gaining practical experience in the production of tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel non-ferrous metal products.

Our broad product range incorporates tungsten-copper compound, molybdenum-copper composite, tungsten-molybdenum combination, high-thickness tungsten amalgam, tantalum composite, niobium combination, and titanium amalgam.

Starting around 2010, we have zeroed in on unfamiliar exchange, providing high-quality non-ferrous metal products to the worldwide market.

Our products are sent out to Taiwan, Ukraine, South Korea, the US, Australia, Germany, Iran, and different nations, laying out long haul helpful associations with our clients. Recognized for our commitment to quality, we have earned high praise from customers worldwide. Our advanced production equipment includes intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, and more, enabling us to deliver superior products consistently.

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging:

- Wooden Crate Packaging: Ensures safe transportation of heavy and large High-Temperature Molybdenum Heater Wire.

- Carton Packaging: Suitable for smaller, lightweight wires, providing protection during transit.

- Foam-Filled Packaging: Protects against mechanical damage and shock during shipping.

- Waterproof and Moisture-Proof Packaging: Essential for preventing corrosion and maintaining product integrity.

- Custom Packaging: Tailored solutions to meet specific customer requirements.

- International Standard Packaging: Complies with global shipping standards to ensure hassle-free delivery.

Logistics:

- Sea Freight: Economical option for large shipments.

- Air Freight: Fast and reliable for urgent deliveries.

- Land Transport: Efficient for regional and cross-border shipping.

- Multimodal Transport: Combines various methods to optimize delivery time and cost.

- Courier Services: Ideal for small parcels and samples, providing quick door-to-door service.

|

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Rich Experience: Over a decade of expertise in producing and exporting high-quality non-ferrous metals.

- Comprehensive Capabilities: From manufacturing to research and development, product testing, and inventory management.

- Advanced Equipment: State-of-the-art production facilities ensuring precision and quality.

- Global Reach: Established partnerships and a robust export network across multiple countries.

- Customer-Centric Approach: Dedicated to providing exceptional service and tailored solutions to meet client needs.

- High-Quality Standards: Commitment to delivering products that meet the highest industry standards.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. supports comprehensive OEM/ODM services, allowing customers to customize products according to their specifications. Our capabilities include design, development, and manufacturing tailored to meet specific requirements, ensuring optimal performance and satisfaction.

|

|

Frequently Asked Questions (FAQ)

-

What is the purity level of your product?

- Our product has a purity level of ≥99.95%, ensuring high performance and reliability.

-

Can you provide custom sizes for product?

- Yes, we offer custom sizes to meet the specific needs of our customers.

-

What are the delivery times for bulk orders?

- Delivery times vary depending on the order size and specifications, but we strive to deliver all orders promptly and efficiently.

-

How do you ensure the quality of your products?

- We employ rigorous quality control measures, including comprehensive testing and inspection at each stage of production.

-

Do you offer technical support for product applications?

- Yes, we provide technical support and guidance to help customers optimize the use of our products in their applications.

Contact Us

For high-quality molybdenum heater wire and exceptional service, choose Shaanxi Peakrise Metal Co., Ltd. We invite global buyers to collaborate with us and experience the superior performance of our products. Contact us today at info@peakrisemetal.com to discuss your requirements and explore how we can support your business.