tungsten nickel copper alloy

Material:Tungsten Nickel Copper Alloy

Grade:90W,92.5W,95W,97W

Elongation:≥2%

Density:16.8~18.85g.cm3

Size: According To Customer Drawing

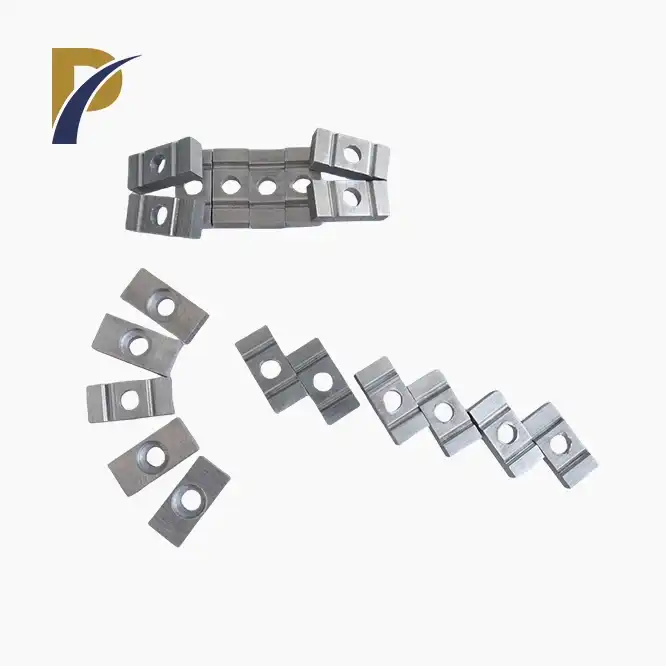

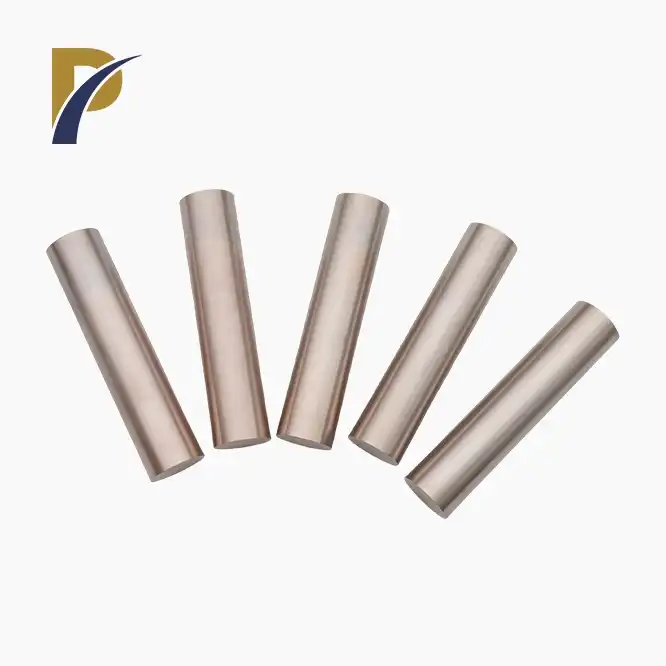

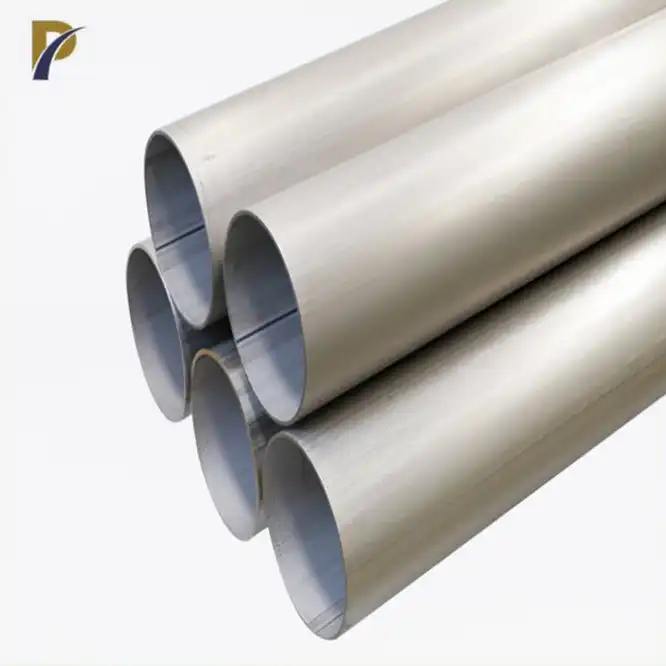

Shape: Rod,Plate,and processed parts

Application: Automotive Industry,Aerospace Industry,Medical Equipment,Sports equipment.

PRODUCT DESCRIPTION

Tungsten Nickel Copper Alloy Introduction

Tungsten Nickel Copper Alloy is a high-density, non-magnetic material with good strength, corrosion resistance, and electrical conductivity.

Shaanxi Peakrise Metal Co., Ltd. is a top provider of tungsten nickel copper alloy, known for our expertise and dedication to quality. We use cutting-edge technology and considerable industry knowledge to create alloys that meet the highest standards, responding to the different demands of our worldwide customers.Product Parameters

| Property | Value |

|---|---|

| Tungsten Content (%) | 90-97 |

| Nickel Content (%) | 3-7 |

| Copper Content (%) | 0.5-3 |

| Density (g/cm³) | 17.0-18.5 |

| Electrical Conductivity (% IACS) | 15-30 |

| Thermal Conductivity (W/m·K) | 150-200 |

| Hardness (HB) | 250-300 |

| Tensile Strength (MPa) | 600-800 |

| Melting Point (°C) | 2,600-3,400 |

| Coefficient of Thermal Expansion (10^-6/°C) | 5-7 |

|

|

Physical and Chemical Properties

It is characterized by:

High Density: The tungsten nickel copper alloy's density ranges from 17.0 to 18.5 g/cm³, providing excellent stability and resistance to deformation.

Thermal Conductivity: With thermal conductivity between 150 and 200 W/m·K, it effectively dissipates heat.

Electrical Conductivity:

The alloy retains good electrical conductivity, between 15 and 30% IACS, making it suitable for electrical applications.Hardness: It features a hardness range of 250 to 300 HB, ensuring durability and wear resistance.

High Melting Point: The alloy has a melting point between 2,600 and 3,400°C, enabling performance at high temperatures.

|

|

Product Functions

High Density:

The high density of it provides stability and minimizes vibration, crucial for precision applications.

Corrosion Resistance:

The tungsten nickel copper alloy's excellent resistance to corrosion extends the lifespan of components in challenging environments.

Thermal stability is the ability to withstand extreme temperatures without degradation, making it appropriate for high-temperature applications

Electric Conductivity:It efficiently conducts electricity, making it suitable for electrical and electronic applications.

Eechanical Strength:

The alloy's high tensile strength ensures durability and reliability in demanding conditions.

Product Applications

Aerospace Components:

Used in aircraft for components that need to be strong, stable, and resistant to harsh temperatures.

Radiation Shielding:

The high density of it makes it suitable for shielding against radiation in medical and industrial applications.

Industrial Machinery:

Employed in manufacturing equipment subject to wear and tear, providing durability and reliability.

Electrical contacts have strong conductivity and arc resistance, making them ideal for high-voltage and high-current applications.

Heat Sinks:

Effective in dissipating heat in electronic devices, ensuring optimal performance and longevity.

|

|

Production Method

Blending Powder:

To get the right composition, high-purity tungsten, nickel, and copper powders are precisely measured and combined.

Compaction:

The powder mixture is compacted under high pressure to form a solid green compact.

Sintering:

The compact is sintered at high temperatures in a controlled atmosphere, bonding the particles and forming a dense material.

Infiltration:

The sintered part may undergo copper infiltration to enhance its properties and ensure uniform distribution of materials.

Machining:

The final product is machined to precise dimensions and specifications, ensuring it meets the required standards.

|

|

|

Overview of the Company

Shaanxi Peakrise Metal Co., Ltd. is a prominent manufacturer and supplier of nonferrous metal alloys, such as nickel, titanium, zirconium, zinc, tantalum, niobium, and tungsten.

Our tungsten nickel copper alloy range includes over 100 distinct goods, each of which is customized to the specific needs of our global clients.Since 2010, we have been exporting high-quality nonferrous metal products and have established strong relationships with customers in Taiwan, the United States, Australia, Germany, Iran, the Ukraine, South Korea, and other countries.

Our goods are renowned for their dependability and excellent quality.

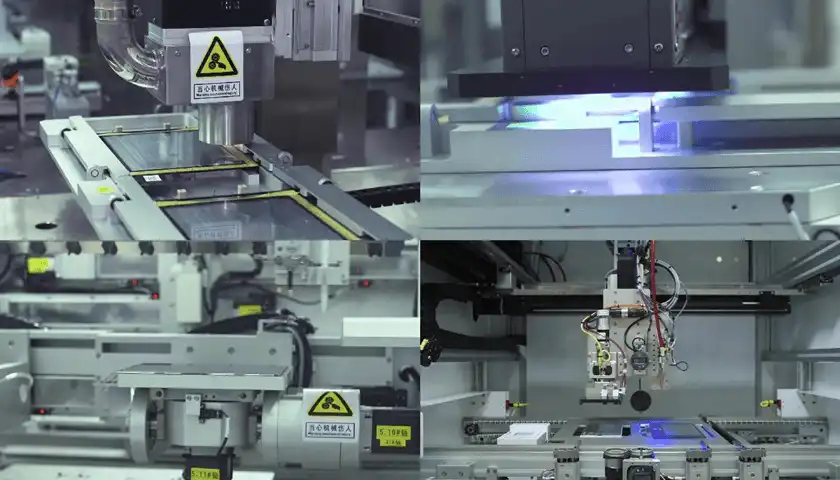

In addition to vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, vacuum annealing furnaces, rolling mills, wire drawing machines, plasma welding rooms, lathes, milling, sawing, drilling, shears, stamping and cutting equipment, grinders, straightening, CNC machines, and other advanced production equipment, we have a wide range of these machines.This makes it possible for us to continuously provide top-notch goods and services.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

Packaging Options:

Wooden crate packing.Carton packing

Foam-filled packaging

Waterproof and moisture-proof packing.

Custom packaging

International standard packaging

Logistics Options:

Sea Freight

Air Freight

Land transportation

Multimodal transportation

Express delivery services.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Detailed Knowledge: Ten years plus of experience in the manufacturing and distribution of non-ferrous metals.

Superior Goods:

dedication to providing goods that satisfy the highest standards of quality.

Cutting-edge Technology:

cutting-edge production facilities and machinery.

Global Reach:

Established export network and long-term relationships with international clients.

Customer-Centric Approach:

Focus on customer satisfaction and tailored solutions to meet specific needs.

|

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services, providing customized solutions to meet the unique requirements of our clients.

To ensure high-quality and dependable performance, our expert team collaborates directly with clients to design and manufacture products that suit their specifications.

|

|

Frequently Asked Questions (FAQ)

What's the usual composition of products?

They are generally composed of 90-97% tungsten, 3-7% nickel, and 0.5-3% copper, depending on the required characteristics.

What are the primary applications of products?

Common applications include aerospace components, radiation shielding, industrial machinery, electrical contacts, and heat sinks.

How does products perform in high-temperature environments?

It exhibits excellent thermal stability, making it suitable for use in extreme temperatures.

Can you provide custom sizes and shapes for the products?

Yes, we offer OEM/ODM services and can customize products to meet specific client requirements.

What are shipping alternatives for foreign orders?We provide a variety of logistical alternatives, including sea freight, air freight, land transport, multimodal transport, and rapid delivery.

Contact us

We urge international buyers to collaborate with Shaanxi Peakrise Metal Co., Ltd. on high-quality tungsten nickel copper alloys and other nonferrous metal goods.

Our commitment to quality and customer satisfaction ensures that you receive the best products and services.

For further information or to make an order, please contact info@peakrisemetal.com.We look forward to working with you and meeting your needs with our high-quality products and solutions.