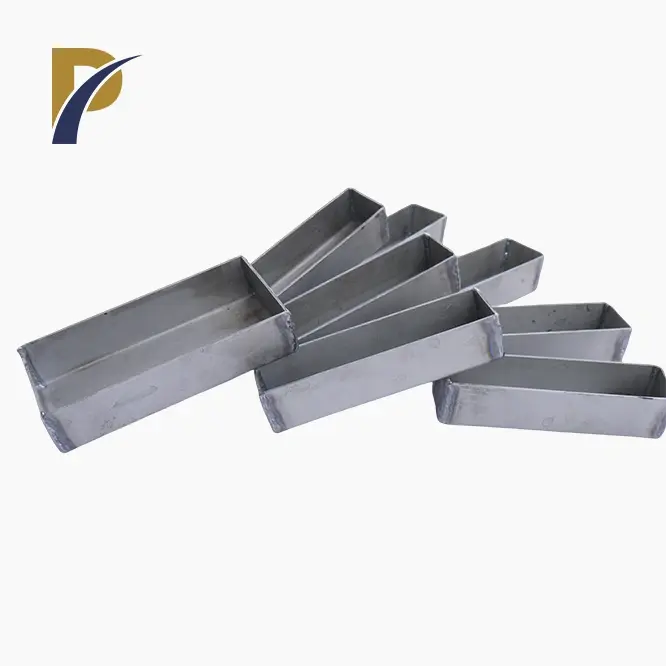

molybdenum lanthanum furnace boats

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

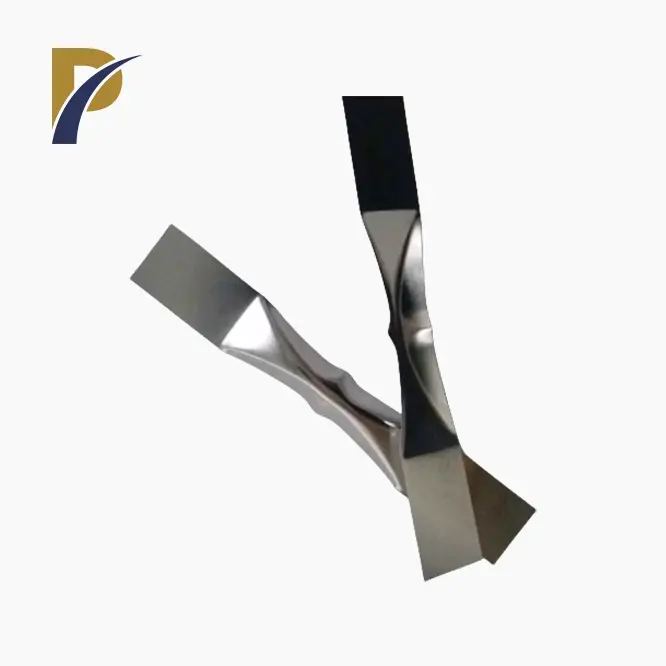

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Molybdenum Lanthanum Furnace Boats Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is a premier supplier of high-quality molybdenum lanthanum furnace boats. These boats are widely recognized in the industry for their superior performance, durability, and reliability. Molybdenum lanthanum alloy (Mo-La) is a combination of molybdenum and a small percentage of lanthanum oxide, which enhances the material’s high-temperature strength and creep resistance. This makes it an ideal choice for various high-temperature applications, especially in the field of furnace components. Our Lanthanated Molybdenum Boats are meticulously manufactured to meet the stringent demands of industries such as electronics, aerospace, and chemical processing.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Molybdenum-Lanthanum Alloy (Mo-La) |

| Lanthanum Content | 0.1-0.2% |

| Purity of Molybdenum | ≥ 99.95% |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Maximum Operating Temperature | 1800°C |

| Tensile Strength | 610 MPa |

| Elongation | ≥ 20% |

| Thermal Conductivity | 138 W/m·K |

| Electrical Resistivity | 5.2 µΩ·cm |

| Dimensions (L x W x H) | Customizable |

| Surface Finish | Bright, Clean |

| Manufacturing Technique | Powder Metallurgy, Rolling, Riveting |

|

|

Physical and Chemical Properties

molybdenum lanthanum furnace boats exhibits outstanding physical and chemical properties:

High Melting Point: With a melting point of 2620°C, it remains stable under extreme temperatures.

Superior Strength: The alloy offers excellent tensile strength of 610 MPa, ensuring durability.

Enhanced Creep Resistance: Lanthanum addition significantly improves the creep resistance of the alloy.

Excellent Thermal Conductivity: With a thermal conductivity of 138 W/m·K, it efficiently dissipates heat.

Corrosion Resistance: High resistance to oxidation and corrosion makes it suitable for harsh environments.

|

|

Molybdenum Lanthanum Furnace Boats Functions

High-Temperature Stability: Capable of withstanding extreme temperatures, making it ideal for high-temperature furnaces.

Durability: The addition of lanthanum oxide enhances the alloy's durability and resistance to wear and tear.

Thermal Conductivity: Efficiently conducts heat, ensuring uniform temperature distribution within the furnace.

Corrosion Resistance: Resistant to oxidation and corrosion, extending the product’s lifespan.

Customizability: Available in customizable dimensions to meet specific application requirements.

Product Applications

Electronics Industry: molybdenum lanthanum furnace boats are used in the manufacturing of semiconductor devices and other electronic components.

Aerospace Industry: Essential for high-temperature applications such as rocket nozzles and heat shields.

Chemical Processing: Suitable for use in chemical reactors and high-temperature processing equipment.

Metallurgy: Utilized in the melting and processing of metals and alloys.

Glass Manufacturing: Ideal for use in glass melting and forming applications due to its high thermal stability.

|

|

Production Process

Powder Metallurgy: Starting with high-purity molybdenum powder mixed with lanthanum oxide.

Pressing: The mixture is pressed into desired shapes.

Sintering: The pressed shapes are sintered in a high-temperature furnace to achieve the desired density and strength.

Rolling: Sintered pieces are rolled to improve mechanical properties.

Riveting: Final assembly involves riveting to ensure structural integrity.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts state-of-the-art production facilities equipped with advanced machinery. Our production equipment includes:

- Intermediate frequency sintering furnace

- Vacuum arc melting furnace

- Laser cutter

- Plasma electron beam melting furnace

- Vacuum annealing furnace

- Various rolling mills

- Wire drawing machines

- Plasma welding rooms

- Lathes, milling machines, sawing machines, drilling machines

- Shears, stamping equipment, cutting equipment, grinders, straightening machines, CNC

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging:

- Wooden crate packaging

- Carton packaging

- Foam-filled packaging

- Waterproof and moisture-proof packaging

- Custom packaging to meet international standards

Logistics:

- Sea freight

- Air freight

- Land transportation

- Multimodal transportation

- Express delivery services

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Expertise: Decades of experience in the production of refractory metals.

Quality Assurance: Strict quality control measures to ensure product reliability.

Advanced Facilities: Equipped with state-of-the-art machinery and technology.

Global Reach: Products exported to numerous countries with established long-term customer relationships.

Customer Satisfaction: High customer recognition and positive evaluations.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services, allowing for customized production to meet specific customer requirements. Our team of experts works closely with clients to deliver tailored solutions.

|

|

Frequently Asked Questions

What is the maximum operating temperature of Molybdenum Lanthanum Furnace Boats?

The maximum operating temperature is 1800°C.

Can you provide custom dimensions for the furnace boats?

Yes, we offer customizable dimensions to meet your specific needs.

What is the purity of the molybdenum used?

The molybdenum purity is ≥ 99.95%.

How do you ensure the quality of your products?

We employ stringent quality control measures and use advanced testing equipment.

Do you offer international shipping?

Yes, we provide international shipping through various logistics options.

Contact Us

Ready to enhance your high-temperature applications with our molybdenum lanthanum furnace boats? Reach out to Shaanxi Peakrise Metal Co., Ltd. today! Our team is eager to assist you with your requirements and provide you with high-quality, reliable products. Contact us at info@peakrisemetal.com to get started.