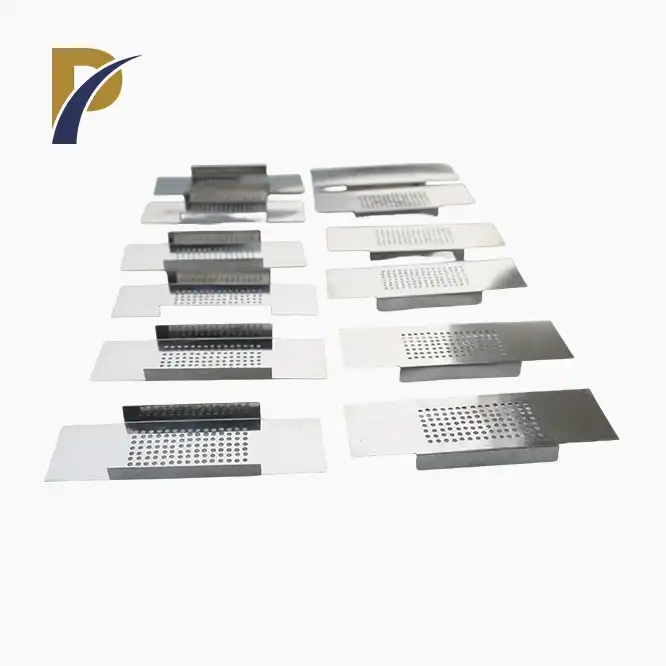

molybdenum vacuum boat

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Molybdenum Vacuum Boat Product Introduction

Shaanxi Peakrise Metal Co., Ltd is a leading supplier of molybdenum vacuum boat, which are essential components in high-temperature vacuum and inert gas environments. Our products are widely used in the metallurgical, electronics, and aerospace industries for their exceptional properties, including high melting point, excellent thermal conductivity, and corrosion resistance. As a trusted supplier, Shaanxi Peakrise Metal Co., Ltd ensures the highest quality standards in manufacturing, catering to the specific needs of global clients.

Product Parameters

| Parameter | Value |

|---|---|

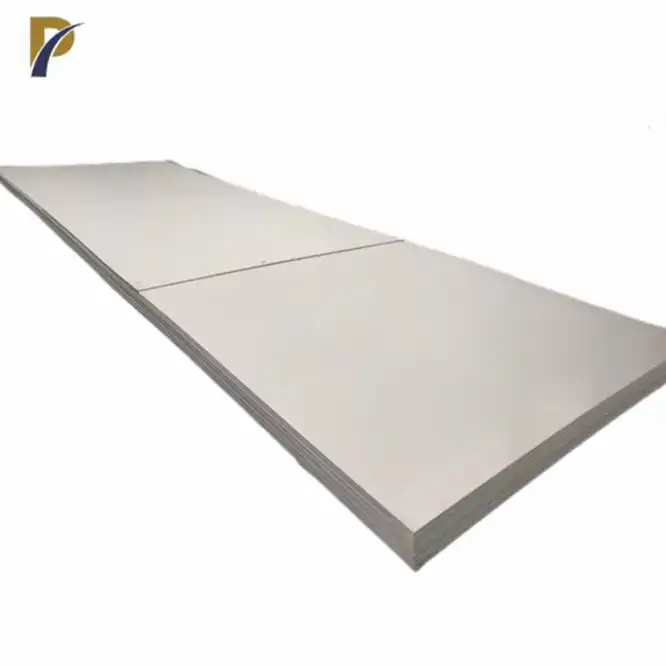

| Material | MoLa (Molybdenum Lanthanum) |

| Purity | ≥ 99.95% |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Size Range (Length) | 50-500 mm |

| Size Range (Width) | 20-200 mm |

| Size Range (Height) | 10-100 mm |

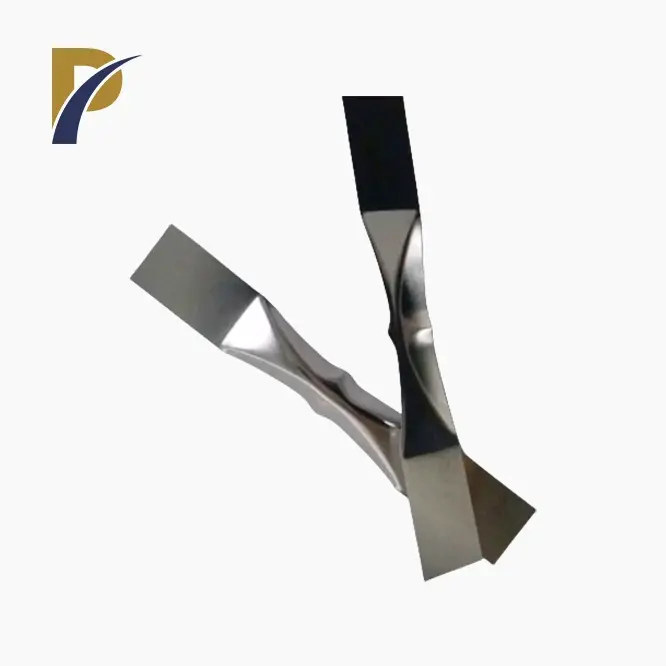

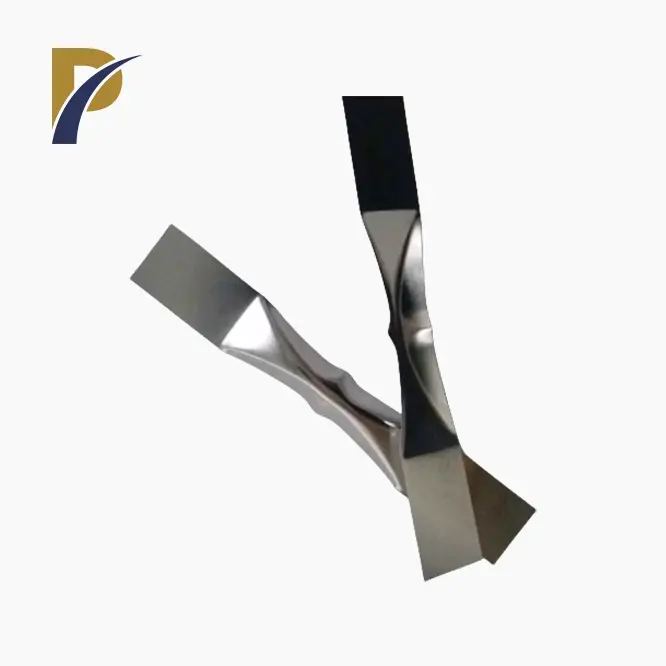

| Tensile Strength | 700 MPa |

| Hardness | 230 HV |

|

|

|

Physical and Chemical Properties

High Melting Point: With a melting point of 2620°C, our molybdenum vacuum boat performs exceptionally well in high-temperature environments.

Excellent Thermal Conductivity: Molybdenum’s superior thermal conductivity ensures efficient heat distribution, crucial for uniform heating processes.

Corrosion Resistance: Our Molybdenum Vacuum Boats exhibit excellent resistance to oxidation and chemical corrosion, ensuring long-term reliability.

High Purity: Manufactured with a purity of ≥ 99.95%, our molybdenum boats maintain stability and performance even under extreme conditions.

|

|

Molybdenum Vacuum Boat Functions

High-Temperature Resistance: Capable of withstanding extreme temperatures, ensuring durability and performance in demanding environments.

Uniform Heating: Excellent thermal conductivity allows for uniform heat distribution, essential for precise processing applications.

Corrosion Resistance: Resists oxidation and corrosion, making it suitable for long-term use in harsh environments.

High Strength and Durability: Molybdenum's high tensile strength and hardness provide structural integrity and prolonged lifespan.

Product Applications

Metallurgical Industry: molybdenum vacuum boat is used in sintering and melting processes due to high-temperature stability and resistance to molten metals.

Electronics Industry: Essential in the fabrication of semiconductor devices and thin-film deposition processes.

Aerospace Industry: Utilized in high-temperature applications, such as components for spacecraft and jet engines.

Chemical Processing: Ideal for use in corrosive environments due to its excellent resistance to chemical attacks.

|

|

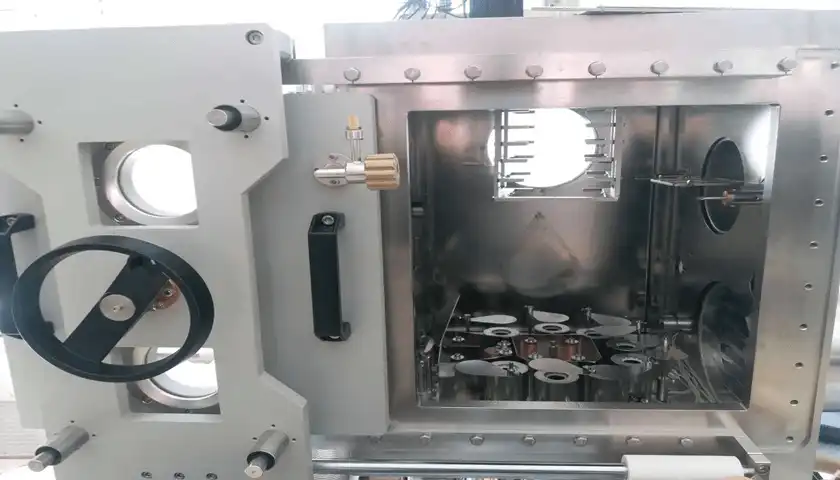

Product Process and Production Flow

Material Selection: High-purity molybdenum powder is chosen to ensure optimal performance.

Powder Metallurgy: The powder is compacted and sintered at high temperatures to form dense, robust boats.

Machining: Precision machining ensures the boats meet exact dimensional specifications.

Quality Control: Each product undergoes rigorous testing to ensure it meets our strict quality standards.

Packaging: Secure packaging protects the boats during transportation and storage.

|

|

|

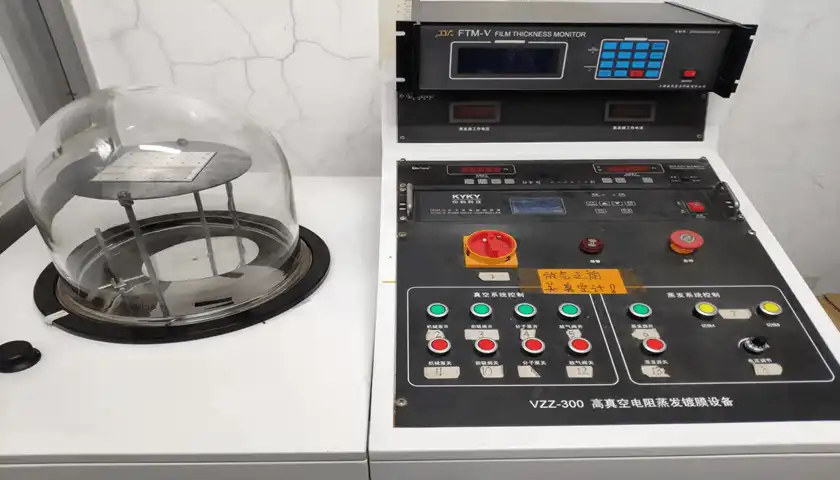

Our Factory

Shaanxi Peakrise Metal Co., Ltd is equipped with state-of-the-art production facilities, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, and plasma electron beam melting furnaces. Our experienced team and advanced equipment enable us to produce high-quality product that meet the stringent requirements of our clients worldwide.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

Wooden Crate Packaging: Ensures protection against physical damage during transport.

Cardboard Box Packaging: Suitable for smaller shipments and added convenience.

Foam-Filled Packaging: Provides cushioning to prevent damage from impacts.

Waterproof and Moisture-Proof Packaging: Protects against environmental factors.

Custom Packaging: Tailored to meet specific client requirements.

International Standard Packaging: Complies with global shipping standards for safe delivery.

Logistics

Sea Freight: Cost-effective solution for large shipments.

Air Freight: Fast delivery for urgent orders.

Land Transport: Reliable and flexible for regional deliveries.

Multimodal Transport: Combines different modes for optimal efficiency.

Courier Services: For smaller, time-sensitive shipments.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Extensive Experience: Over a decade of expertise in producing high-quality non-ferrous metal products.

Advanced Production Facilities: Equipped with cutting-edge technology for precision manufacturing.

Global Reach: Established long-term partnerships with clients worldwide.

Quality Assurance: Rigorous testing and quality control ensure product reliability.

Comprehensive Services: From material selection to custom packaging, we provide end-to-end solutions.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd offers comprehensive OEM and ODM services to meet the specific needs of our clients. Our experienced team works closely with customers to develop custom solutions that meet exact specifications and performance requirements.

|

|

Frequently Asked Questions (FAQs)

- What is the maximum operating temperature for the products? Vacuum Molybdenum Boats can operate at temperatures up to 2620°C.

- How do you ensure the quality of your products? We use high-purity materials and conduct rigorous quality control tests to ensure each product meets our high standards.

- Can you provide custom sizes for the products? Yes, we offer custom manufacturing to meet the specific dimensions required by our clients.

- What industries commonly use the products? They are widely used in the metallurgical, electronics, aerospace, and chemical processing industries.

- How do you package the products for shipment? We use a variety of packaging methods, including wooden crates, cardboard boxes, foam-filled packaging, and waterproof protection to ensure safe delivery.

Contact Us

We invite global procurement professionals to partner with Shaanxi Peakrise Metal Co., Ltd. For high-quality molybdenum vacuum boat and exceptional customer service, please contact us at info@peakrisemetal.com. We look forward to working with you to meet your specific needs and exceed your expectations.