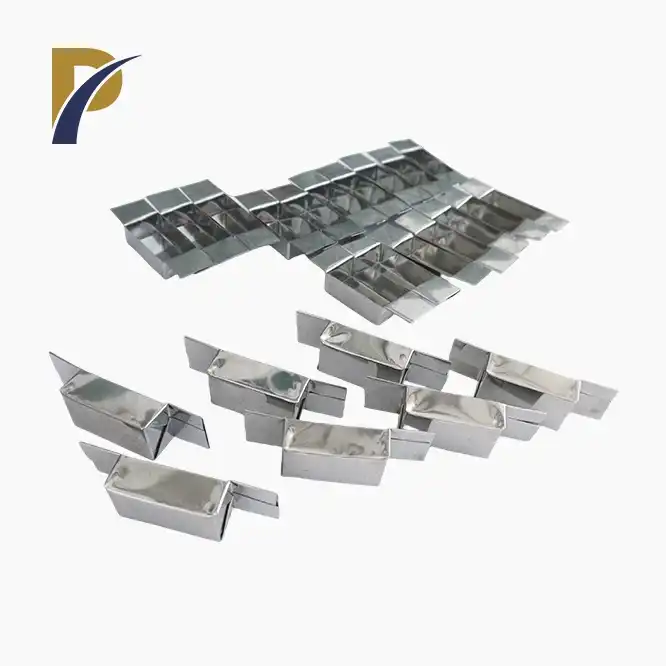

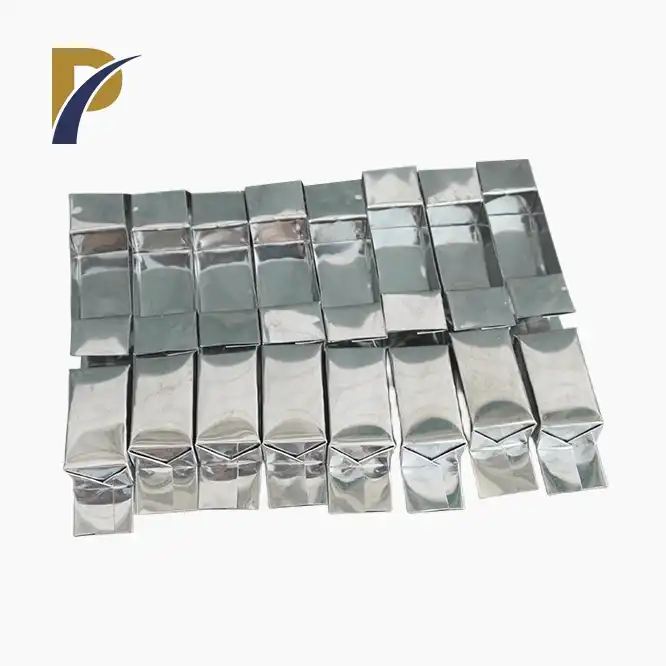

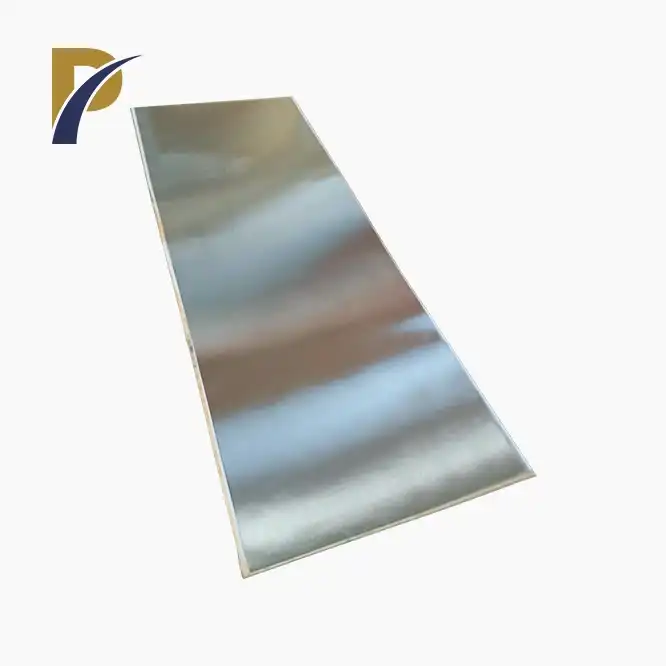

molybdenum evaporation boats

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Molybdenum Evaporation Boats Introduction

Shaanxi Peakrise Metal Co., Ltd. is pleased to be your dependable supplier of high-quality molybdenum evaporation boats. Our specialization lies in conveying accurately designed arrangements custom-fitted for the worldwide market. With a powerful skill in non-ferrous metal creation, we take special care of a wide exhibit of modern necessities with greatness and development.

Whether you are associated with semiconductor creation, optical designing, or high-level exploration, our molybdenum evaporation boats are intended to meet your particular necessities with strength, consistency, and unrivaled usefulness. For unrivaled expertise and superior service in non-ferrous metal solutions tailored to your industrial requirements, work with Shaanxi Peakrise Metal Co., Ltd.

Product Specifications

| Property | Value |

|---|---|

| Material | Pure Molybdenum |

| Density | 10.2 g/cm³ |

| Melting Point | 2,623°C (4,753°F) |

| Purity | ≥ 99.95% |

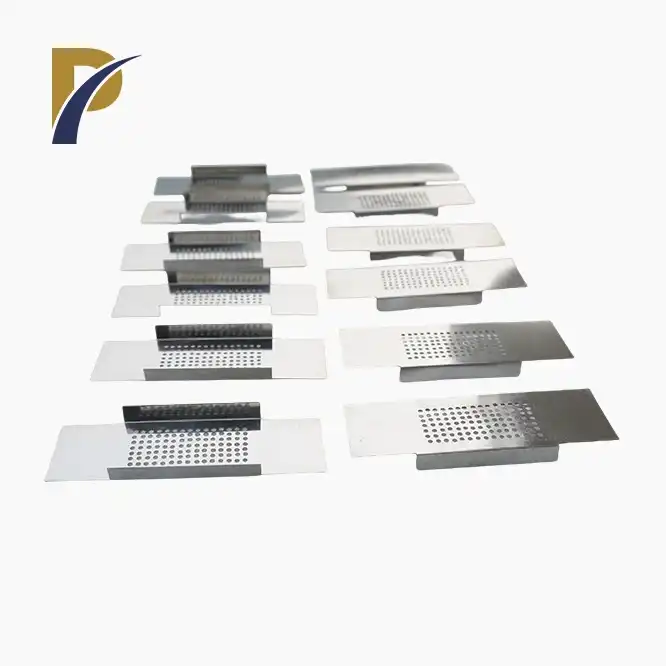

| Dimensions | Customizable |

| Surface Finish | Ground or Polished |

| Application | Vacuum Deposition |

| Max. Temperature | 1,800°C (3,272°F) |

|

|

Physical and Chemical Properties

Molybdenum Evaporation Boats are known for their high melting point, excellent thermal conductivity, and resistance to corrosion in harsh environments. They are crucial in processes requiring precise deposition of metals in vacuum environments.

|

|

Product Features

- High Purity: Our molybdenum evaporation boats are produced to ensure insignificant pollution, guaranteeing a uniform dissipation process. Applications requiring precise deposition and consistent film quality necessitate this high purity level.

- Robust Construction: Our evaporation boats, built to withstand mechanical stress and high temperatures, keep their structural integrity throughout their service life. Even in challenging industrial settings, this resilience ensures dependability.

- Customizable Shapes: To accommodate a variety of configurations and ensure seamless integration into existing systems, each evaporation boat can be customized to fit specific deposition chamber designs. This customization capacity improves adaptability and functional productivity.

- Optimized Heat Transfer: Our boats are designed to improve deposition uniformity and maximize energy utilization during applications of thin-film coatings by facilitating efficient heat transfer. This improvement is fundamental for accomplishing predominant covering quality and efficiency.

- Long-Term Usage: Worked for strength and life span, our evaporation boats convey broadened functional cycles without compromising execution. Due to its longevity, downtime and frequency of maintenance are reduced, increasing productivity and overall cost-effectiveness.

Applications

Our molybdenum evaporation boats find widespread use in:

- Semiconductor Industry: For thin-film deposition in microelectronics.

- Optics Coating: Essential in producing reflective coatings.

- Solar Cells: Facilitates the deposition of photovoltaic layers.

- Medical Equipment: Used in coating medical devices.

|

|

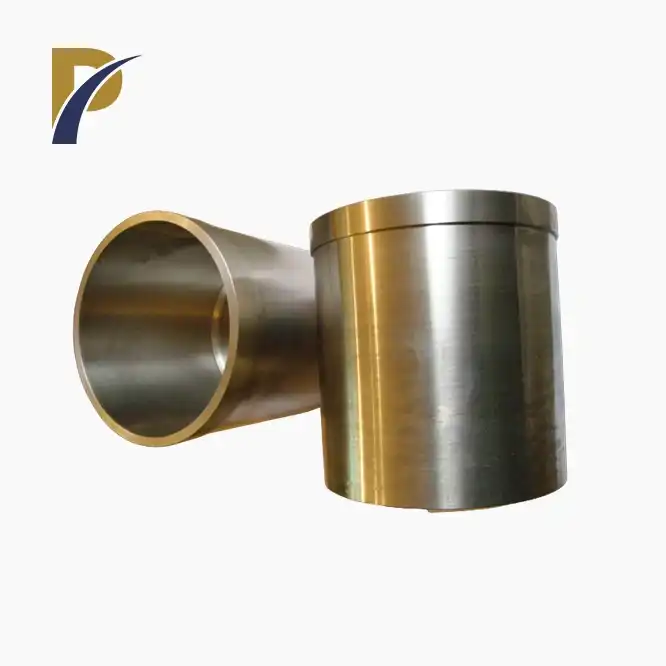

Production Process

At Shaanxi Peakrise Metal Co., Ltd., our evaporation boats are manufactured using advanced processes including vacuum arc melting and precision machining. Each product undergoes rigorous quality control to ensure performance reliability.

|

|

|

Our Manufacturing Facilities

Equipped with state-of-the-art machinery such as vacuum furnaces and precision cutting tools, our facility in Shaanxi supports large-scale production with strict adherence to international standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

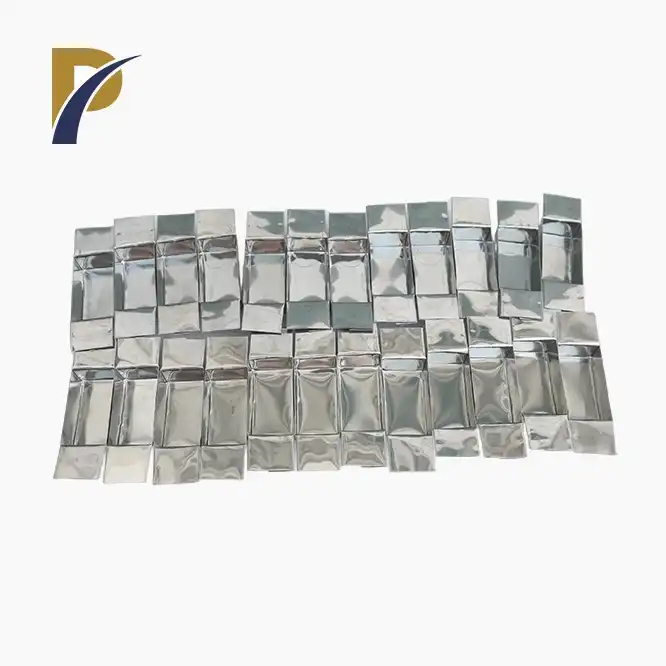

Packaging

We offer a range of packaging options:

- Wooden crates

- Cardboard boxes

- Foam-filled packaging

- Customized packaging to meet specific requirements

Logistics

Choose from our flexible logistics options:

- Sea freight

- Air freight

- Land transportation

- Combined transport solutions

- Expedited delivery services

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Industry Expertise: Over a decade in non-ferrous metal production.

- Global Reach: Trusted by clients worldwide including Taiwan, Ukraine, and the United States.

- Customization: Tailored solutions to meet unique customer specifications.

- Quality Assurance: Committed to delivering high-purity products with consistent performance.

- Customer Support: Dedicated service from inquiry to post-delivery assistance.

|

OEM Services

We offer comprehensive OEM services to meet specific customer demands, ensuring flexibility and customization in production.

|

|

Frequently Asked Questions

-

What is the typical lead time for orders?

- Standard products: 1-2 weeks; Customized products: Depending on specifications.

-

Can you provide certificates of product quality?

- Yes, we offer certificates of conformity and material analysis upon request.

-

Do you support sma orders?

- Yes, we accommodate orders of all sizes, from prototype to bulk production.

-

Are your products compliant with environmental standards?

- Our products adhere to international environmental regulations.

-

What after-sales support do you offer?

- We provide technical support and product warranty to ensure customer satisfaction.

Contact Us

Reach us today at info@peakrisemetal.com to examine how Shaanxi Peakrise Metal Co., Ltd. can meet your molybdenum evaporation boats necessities. Work with us to receive superior service and dependable solutions.

YOU MAY LIKE

-

VIEW MOREmolybdenum riveted boat

VIEW MOREmolybdenum riveted boat -

VIEW MOREmolybdenum lanthanum furnace boats

VIEW MOREmolybdenum lanthanum furnace boats -

VIEW MOREmolybdenum sintering boats

VIEW MOREmolybdenum sintering boats -

VIEW MOREmolybdenum vacuum boat

VIEW MOREmolybdenum vacuum boat -

VIEW MOREfine tungsten wire

VIEW MOREfine tungsten wire -

VIEW MOREmolybdenum sheet /plate for heat shield

VIEW MOREmolybdenum sheet /plate for heat shield -

VIEW MOREtitanium tig welding rod

VIEW MOREtitanium tig welding rod -

VIEW MOREsapphire crucible molybdenum

VIEW MOREsapphire crucible molybdenum