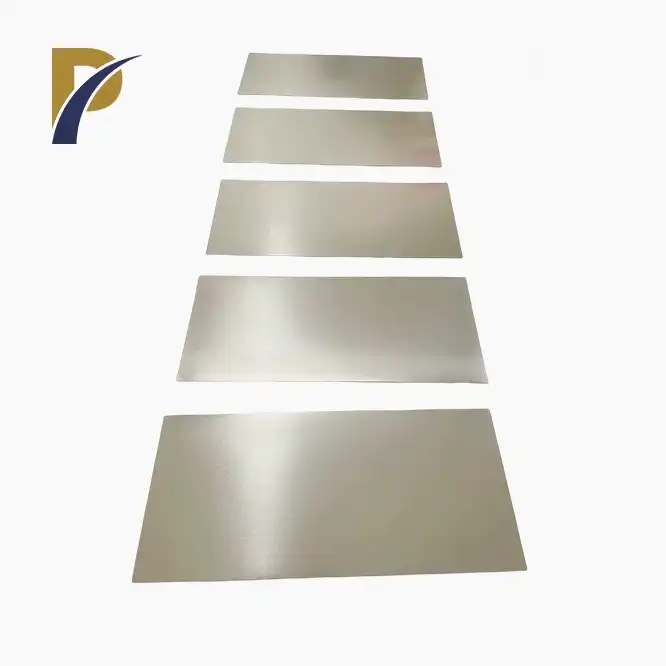

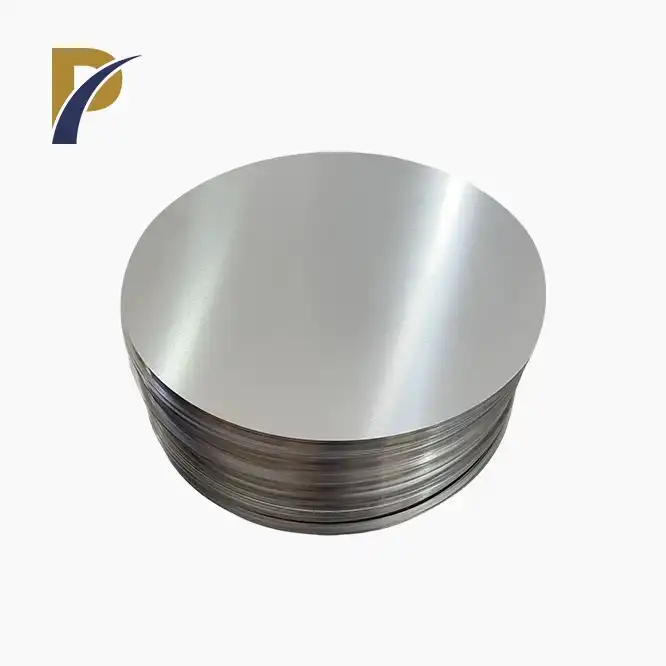

molybdenum sheet /plate for heat shield

Grade: Mo1,TZM,Mo-La,Mo-W Alloy

Purity: 99.95%, 99.97%

Density: 10.2g/cm3

Thickness: 0.2~20mm

Width: 10~700mm

Length: <2500mm

Surface: Bright,polished,Alkaline Washing

Standard: ASTM B386

Application: specialty steels. Molybdenum electrodes, vacuum furnace applications, nuclear power, missiles, and airplane parts.

PRODUCT DESCRIPTION

Molybdenum Sheet /Plate for Heat Shield Introduction

Molybdenum sheets and plates are essential materials in the heat shield industry due to their exceptional thermal and mechanical properties. Shaanxi Peakrise Metal Co., Ltd. is a major supplier of molybdenum sheet /plate for heat shield. At Shaanxi Peakrise Metal Co., Ltd., we specialize in the production and supply of products for heat shield applications. With long periods of involvement and mastery in non-ferrous metal creation, we have laid down a good foundation for ourselves as a confided-in provider to clients around the world.

Product Parameters

| Parameter | Value |

|---|---|

| Thickness Range | 0.1mm - 50mm |

| Width Range | Up to 1000mm |

| Length Range | Up to 3000mm |

| Density | 10.2 g/cm³ |

| Purity | ≥ 99.95% |

| Melting Point | 2620°C |

| Thermal Conductivity | 138 W/m·K (at 20°C) |

|

|

Physical and Chemical Properties

Molybdenum sheet /plate for heat shield unique physical and chemical properties that make them ideal for heat shield applications:

- High Melting Point: Molybdenum has a melting point of 2620°C, allowing it to maintain structural integrity at high temperatures.

- Excellent Thermal Conductivity: With a thermal conductivity of 138 W/m·K, molybdenum efficiently dissipates heat, preventing overheating in heat shield systems.

- Low Thermal Expansion: Molybdenum exhibits low thermal expansion, reducing the risk of deformation under thermal stress.

- High Purity: Our molybdenum products have a purity level of ≥ 99.95%, ensuring minimal impurities and optimal performance.

- Corrosion Resistance: Molybdenum offers excellent resistance to corrosion, enhancing the durability and lifespan of heat shields.

|

|

Molybdenum Sheet /Plate for heat shield Functions

Molybdenum sheets and plates serve several critical functions in heat shield applications:

- Thermal Protection: Molybdenum acts as a thermal barrier, protecting sensitive components from extreme heat.

- Heat Dissipation: The high thermal conductivity of molybdenum enables efficient heat dissipation, maintaining temperature stability.

- Structural Integrity: Molybdenum maintains its strength and stability at high temperatures, ensuring the integrity of heat shield structures.

- Corrosion Resistance: Molybdenum’s resistance to oxidation and corrosion ensures long-lasting performance in harsh environments.

Product Applications

Molybdenum sheets and plates are widely used in various heat shield applications due to their superior properties:

- Aerospace Industry: Molybdenum is used in heat shields for spacecraft and aircraft to protect components from high temperatures during re-entry and flight.

- Automotive Industry: molybdenum sheet /plate for heat shield is employed in high-performance vehicles to protect engine and exhaust systems from excessive heat.

- Industrial Furnaces: Molybdenum sheets are used as heat shields in industrial furnaces to protect equipment and maintain temperature control.

- Electronics Industry: Molybdenum plates are utilized in electronic devices to manage heat dissipation and enhance performance.

|

|

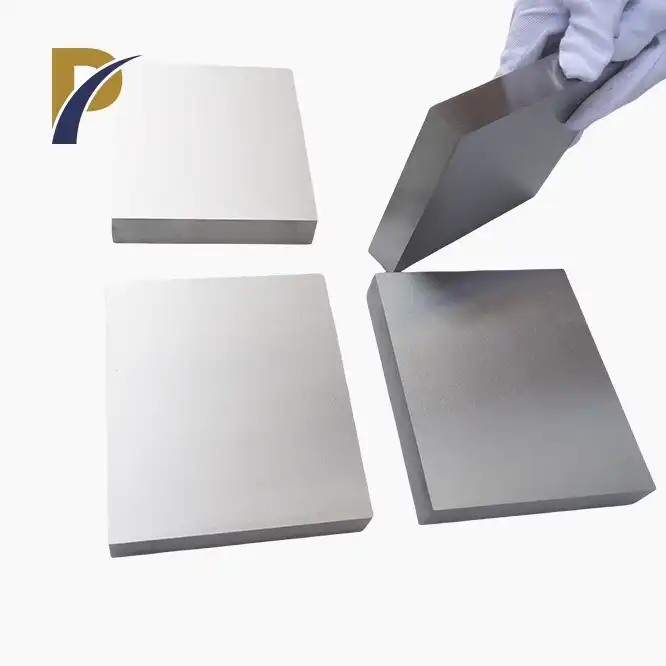

Manufacturing Process

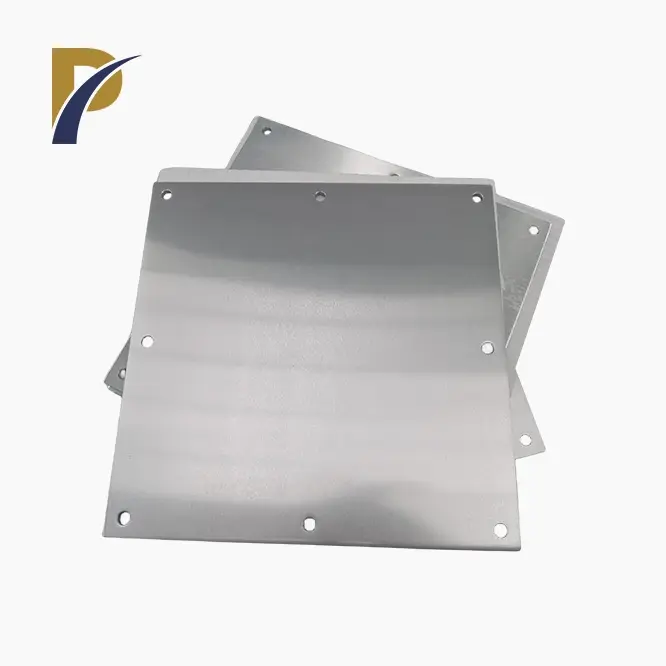

The manufacturing process of molybdenum sheet /plate for heat shield involves several precise steps to ensure the highest quality:

- Raw Material Selection: High-purity molybdenum is sourced and inspected for quality.

- Melting: Molybdenum is melted in a vacuum or inert atmosphere to prevent contamination.

- Rolling: The molten molybdenum is cast into slabs and then rolled into sheets and plates of desired thickness.

- Annealing: The rolled sheets are annealed to relieve internal stresses and improve ductility.

- Surface Treatment: The sheets are treated to remove surface oxides and impurities.

- Quality Inspection: The final products undergo rigorous quality checks to ensure they meet industry standards.

|

|

|

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is a driving producer of non-ferrous metals, specializing in the generation of tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel amalgams. With a comprehensive item extension and progressed generation offices, we serve clients in over 86 nations, including Europe, America, Japan, South Korea, and Southeast Asia.

Since our foundation in 2010, we have centered on conveying high-quality non-ferrous metal items to the universal showcase. Our commitment to quality and development has earned us acknowledgment as a top-tier provider by industry affiliations. We proceed to grow our capabilities, advertising progressed fabricating, fabric inquiries about and advancement, and broad stock to meet the different needs of our worldwide clientele.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging:

- Wooden Crate Packaging: Ensures safe transportation and storage of molybdenum sheets and plates.

- Carton Packaging: Provides lightweight and cost-effective packaging for smaller quantities.

- Foam Filling Packaging: Offers additional protection against shocks and impacts.

- Waterproof and Moisture-proof Packaging: Prevents damage from moisture and environmental exposure.

- Custom Packaging: Tailored packaging solutions to meet specific customer requirements.

- International Standard Packaging: Complies with global packaging standards for secure shipment.

Logistics:

- Sea Freight: Cost-effective solution for large volume shipments.

- Air Freight: Fast and efficient delivery for urgent orders.

- Land Transportation: Reliable transport for domestic and cross-border deliveries.

- Multimodal Transport: Combines different transportation modes for optimized logistics.

- Courier Services: Rapid and secure delivery for small packages and samples.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Rich Experience: Over a decade of experience in non-ferrous metal production and export.

- High-Quality Products: Commitment to delivering products that meet the highest industry standards.

- Advanced Facilities: Equipped with state-of-the-art production equipment for superior manufacturing.

- Global Reach: Products exported to over 86 countries with long-term customer relationships.

- Comprehensive Services: Offering manufacturing, processing, R&D, testing, and inventory solutions.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. provides comprehensive OEM and ODM services, allowing customers to customize molybdenum sheet /plate for heat shield according to their specific requirements. Our experienced team works closely with clients to deliver tailored solutions that meet their unique needs.

|

|

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity for molybdenum sheets?

- The minimum order quantity is typically 10 kg, but we can accommodate smaller orders based on customer requirements.

-

Can you provide custom sizes for molybdenum sheets?

- Yes, we offer custom sizes and thicknesses to meet specific customer needs.

-

What are the lead times for orders?

- Lead times vary depending on the order size and specifications, but we strive to deliver within 4-6 weeks.

-

How do you ensure the quality of your molybdenum products?

- Our products undergo rigorous quality control checks, including chemical composition analysis and mechanical testing.

-

Do you offer technical support for product applications?

- Yes, our technical team is available to provide support and guidance on the optimal use of our molybdenum products.

Contact Us

Partner with Shaanxi Peakrise Metal Co., Ltd. for your molybdenum sheet /plate for heat shield needs. Our high-quality products, comprehensive services, and commitment to excellence make us the ideal choice for heat shield applications. For inquiries and orders, please get in touch with us at info@peakrisemetal.com. We look forward to collaborating with you to meet your specific requirements and enhance your project’s success.