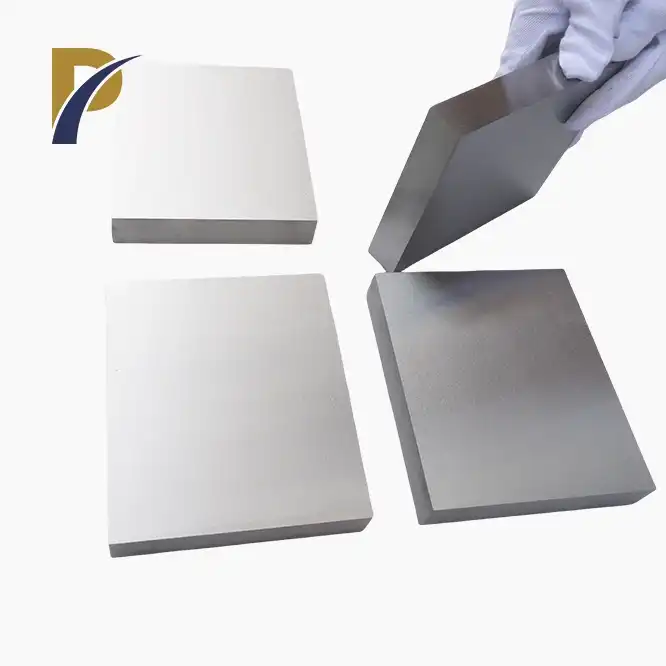

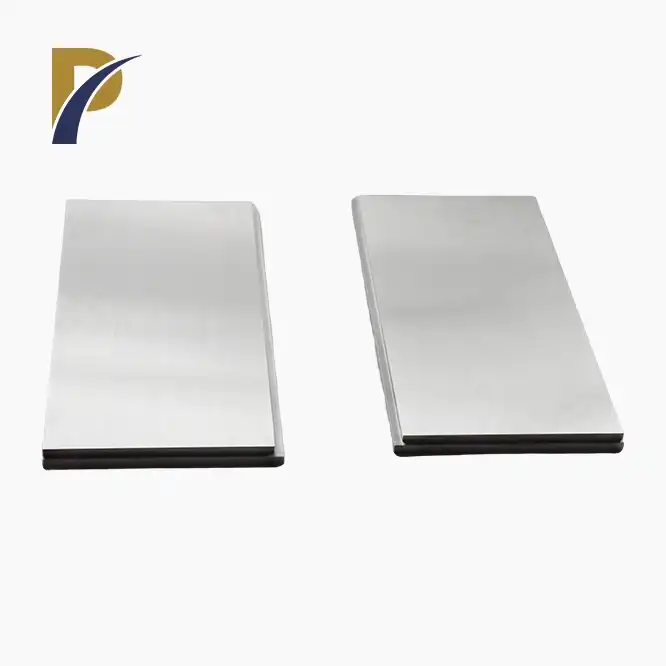

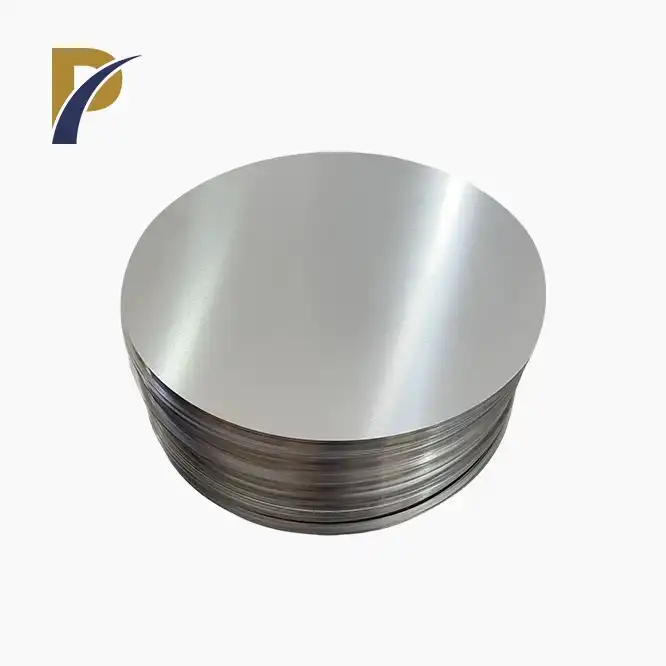

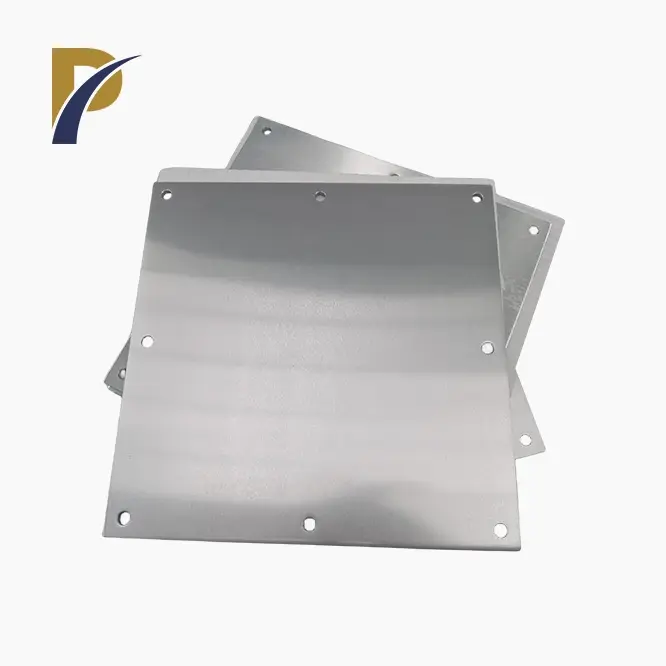

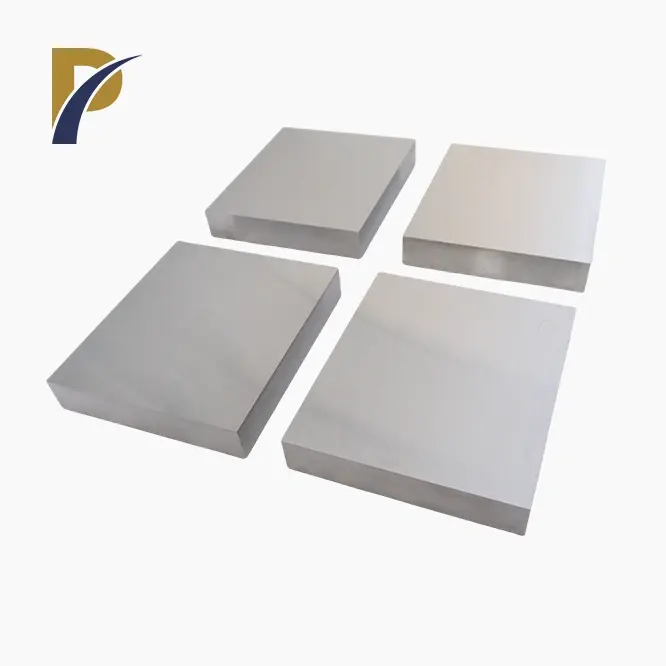

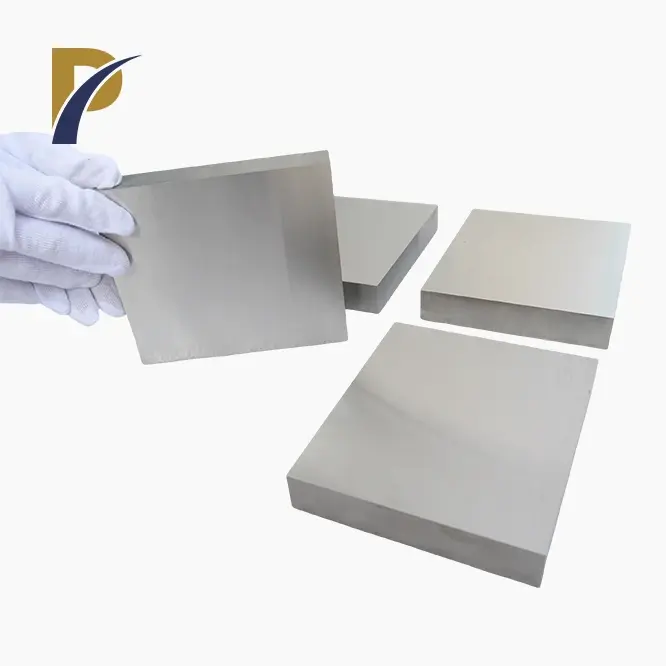

rolling molybdenum plate

Grade: Mo1,TZM,Mo-La,Mo-W Alloy

Purity: 99.95%, 99.97%

Density: 10.2g/cm3

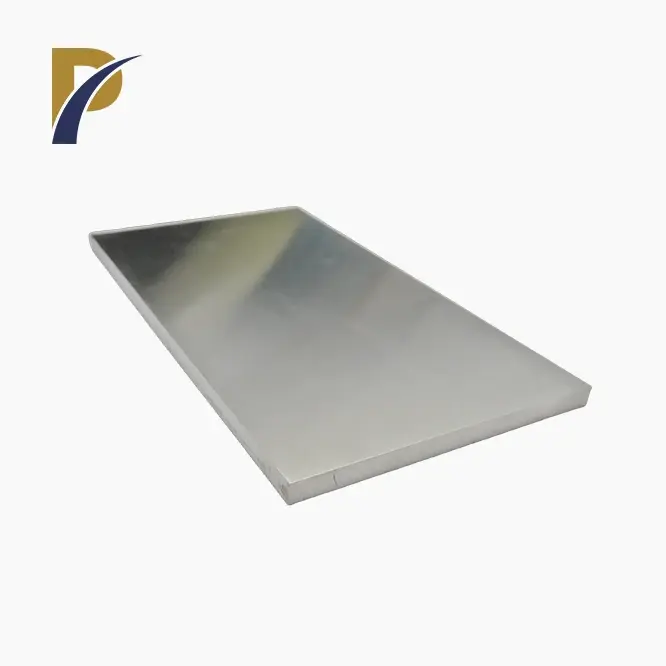

Thickness: 0.2~20mm

Width: 10~700mm

Length: <2500mm

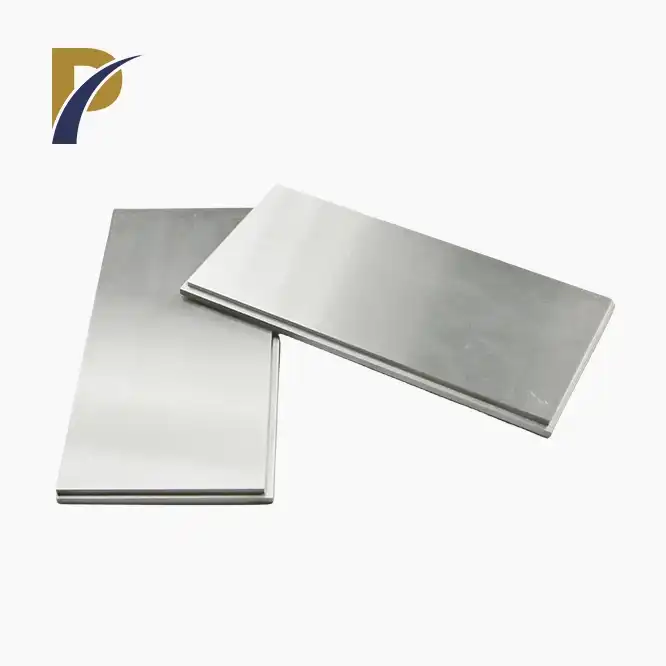

Surface: Bright,polished,Alkaline Washing

Standard: ASTM B386

Application: specialty steels. Molybdenum electrodes, vacuum furnace applications, nuclear power, missiles, and airplane parts.

PRODUCT DESCRIPTION

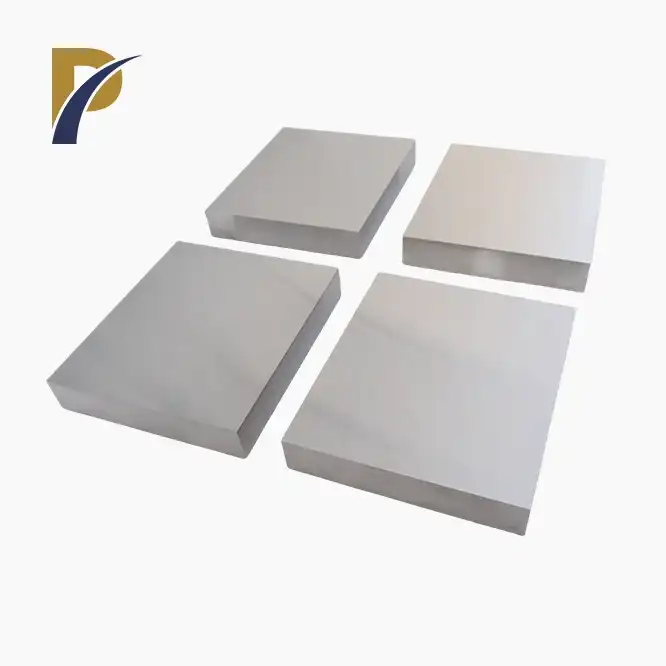

Rolling Molybdenum Plate Product Introduction

Rolling molybdenum plate are an essential component in a variety of applications that are subject to high temperatures and high stresses due to their exceptional properties, which include a high melting point, excellent thermal and electrical conductivity, and significant resistance to creep and corrosion.

These plates are key in enterprises like aviation, safeguard, gadgets, and atomic power. Shaanxi Peakrise Metal Co., Ltd. is a professional supplier that makes high-quality products to meet the specific needs of our global customers. Our items are created utilizing progressed fabricating strategies and severe quality control cycles to guarantee ideal execution and dependability in even the most requesting conditions.

Our more than a decade of experience in the non-ferrous metals industry has earned us a reputation as a trustworthy partner for high-grade molybdenum products, providing solutions that increase productivity and durability.

Product Parameters

| Property | Value |

|---|---|

| Purity | ≥ 99.95% |

| Thickness Range | 0.1mm - 50mm |

| Width Range | 30mm - 600mm |

| Length Range | 30mm - 2000mm |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Tensile Strength | 690 MPa |

| Property | Value |

|---|---|

| Hardness (HV) | 250-350 |

| Electrical Conductivity | 34% IACS |

| Thermal Conductivity | 138 W/m·K |

| Specific Heat Capacity | 0.256 J/g·K |

| Thermal Expansion Coefficient | 5.1 µm/m·K |

| Elastic Modulus | 330 GPa |

| Property | Value |

|---|---|

| Grain Size | ≤ 50 µm |

| Yield Strength | ≥ 550 MPa |

| Elongation | ≥ 15% |

| Poisson's Ratio | 0.31 |

| Workability | Excellent |

| Surface Finish | Polished/Machined |

|

|

Physical and Chemical Properties

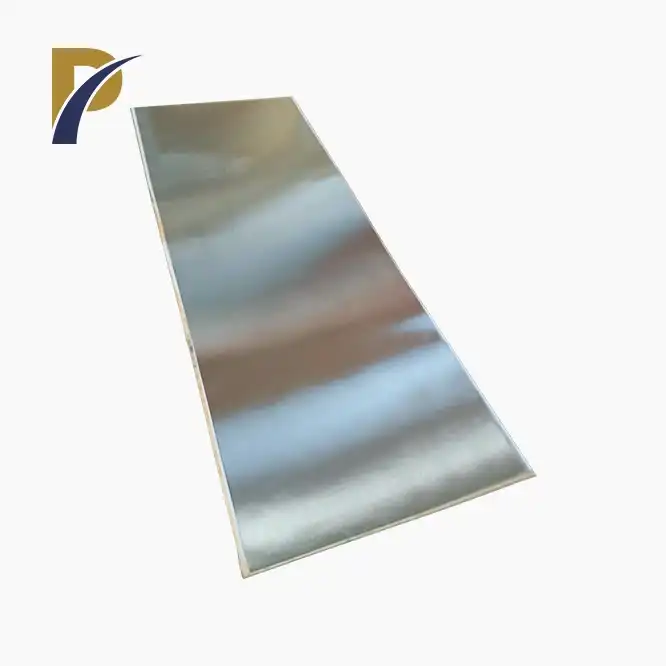

Due to their remarkable chemical and physical properties,Rolling molybdenum plate are suitable for many industrial applications:

High Melting Point: Molybdenum has a melting point of 2620°C, making it ideal for high-temperature applications.

Excellent Conductivity: Superior thermal and electrical conductivity ensures efficient performance in electronic and thermal systems.

Corrosion Resistance: High resistance to corrosion, especially in acidic and alkaline environments, extends the lifespan of components.

Mechanical Strength: High tensile strength and hardness provide durability and resistance to deformation under stress.

Low Thermal Expansion: Minimal thermal expansion reduces the risk of cracking and structural failure under temperature fluctuations.

|

|

Product Functions

-

Heat resistance: Moving molybdenum plates are great for heater parts and high-temperature reactors because of their high dissolving point, which permits them to keep up with their underlying respectability even at incredibly high temperatures.

-

Consumption Impossibility: Due to Rolling Molybdenum Plate superior resistance to substance consumption, molybdenum plates are suitable for use in harsh compound conditions.

-

The Building's Stability: Due to their high tensile strength and low thermal expansion, these plates are ideal for structural applications in the aerospace and defense sectors.

Product Applications

- The Aerospace Sector: utilized in the production of aircraft components and parts that must withstand stress and high temperatures.

- Electronics: They are necessary for the production of semiconductor devices, heat sinks, and electrical contacts due to their excellent thermal conductivity.

- Nuclear Energies: utilized in nuclear reactors and other components requiring high thermal stability and radiation resistance.

- Chemical Treatment: used in equipment that deals with corrosive substances and extreme conditions in chemical plants.

|

|

Manufacturing Process

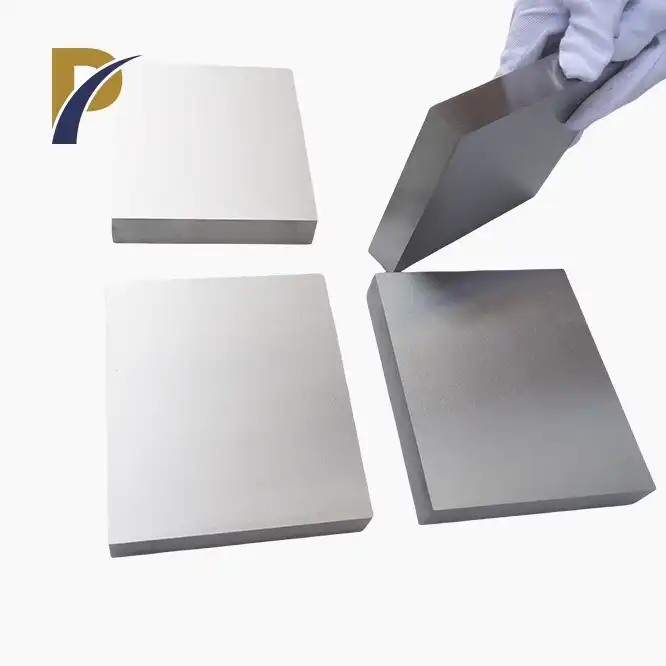

The production of Rolling molybdenum plate at Shaanxi Peakrise Metal Co., Ltd. involves several meticulous steps:

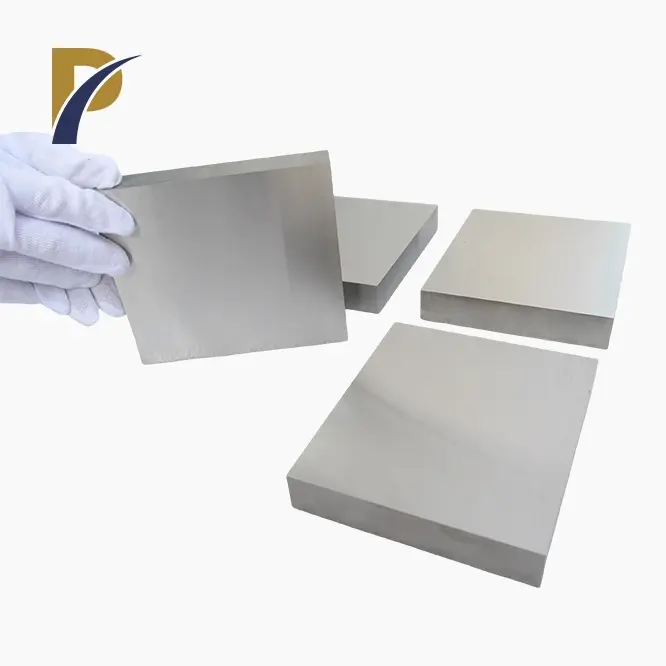

- Raw Material Selection: High-purity molybdenum powder is sourced to ensure the quality of the final product.

- Powder Metallurgy: Molybdenum powder is compacted and sintered at high temperatures to form solid billets.

- Rolling: The billets are hot-rolled or cold-rolled into plates of the desired thickness and dimensions.

- Annealing: Plates are annealed in a vacuum furnace to relieve internal stresses and improve mechanical properties.

- Surface Finishing: Plates are polished or machined to achieve the required surface finish and dimensional accuracy.

- Quality Inspection: Rigorous testing and inspection are conducted to ensure that the plates meet industry standards and customer specifications.

|

|

|

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is the essential maker of solid and non-ferrous metals like tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel blends.

Over the course of more than a decade, we have earned a reputation for providing exceptional customer service and product quality.

Our cutting edge creation offices and talented labor force empower us to convey elite execution materials that fulfill the severe needs of different ventures.

We have established long-term partnerships with global industry leaders thanks to our dedication to quality and innovation.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging:

- Wooden Crate Packaging: Provides sturdy protection for large and heavy molybdenum plates during transit.

- Carton Box Packaging: Suitable for smaller, lighter plates, offering convenient handling and storage.

- Foam Filling Packaging: Ensures additional cushioning and protection against impacts and vibrations.

- Waterproof and Moisture-proof Packaging: Essential for protecting plates from environmental damage during transportation.

- Custom Packaging: Tailored solutions to meet specific customer requirements and international shipping standards.

Logistics:

- Sea Freight: Cost-effective solution for bulk shipments over long distances.

- Air Freight: Fastest mode of transport for urgent deliveries.

- Land Transport: Efficient for regional and cross-border transportation within continents.

- Multimodal Transport: Combines different modes of transport to optimize cost and delivery time.

- Express Services: Ensures rapid delivery for smaller, time-sensitive orders.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

-

Broad Information: mastery in the creation of excellent non-ferrous metal items for over 10 years.

-

New Technologies: Prevalent item quality is ensured by state of the art producing offices and testing gear.

-

Global Reach: extensive commodity organization and long-term partnerships with global clients Arrangements that

-

Cover Everything: providing a variety of products and options for customization to satisfy various client requirements.

-

Control of Quality: Item constancy and execution are ensured by thorough quality control systems and confirmations.

-

Keeping the customer in mind: devoted to offering our clients world-class support and service.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services to meet your specific requirements.From design and material selection to production and quality control, our knowledgeable team closely collaborates with clients to develop individualized solutions.Whether you need tailored dimensions, specific alloy compositions, or unique surface treatments, we have the capabilities to deliver products that match your exact specifications.

|

|

FAQs

-

How long does it typically take to roll molybdenum plates?

The lead time can range from four to eight weeks, depending on the size of the order and the specifications.

-

Could you at any point give custom aspects to molybdenum plates?

Yes, we can customize thicknesses and dimensions to meet your requirements.

-

Which certifications in quality do you hold?

Consistency and high quality are guaranteed by the ISO 9001:2015 certification we hold for our products.

-

How do you guarantee that your molybdenum plates are pure?

Throughout the production process, we make use of molybdenum powder that is extremely pure and follow stringent quality control procedures.

-

What methods of payment do you accept?

PayPal, bank transfers, and letters of credit are all options for making payments.

Contact Us

Are you ready to enhance your projects with high-quality Rolling molybdenum plate? Partner with Shaanxi Peakrise Metal Co., Ltd. and experience unparalleled quality and service. Contact us today at info@peakrisemetal.com to discuss your requirements and discover how we can meet your specific needs. We look forward to building a successful partnership with you!