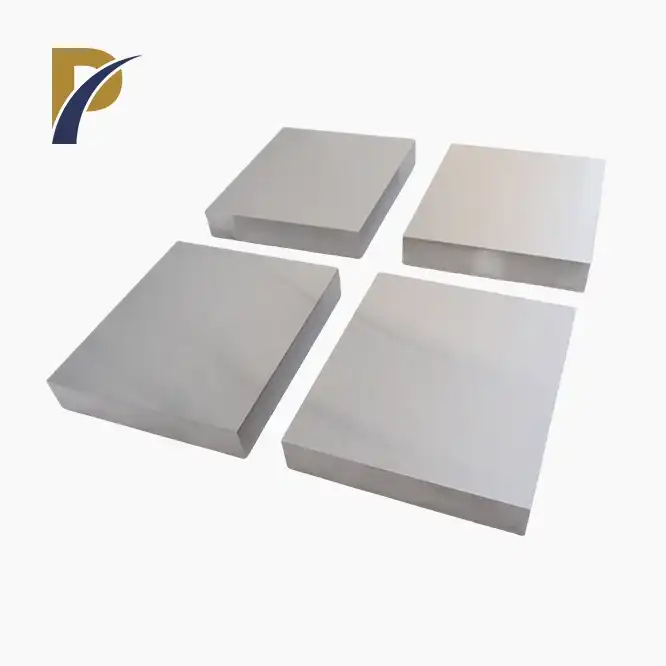

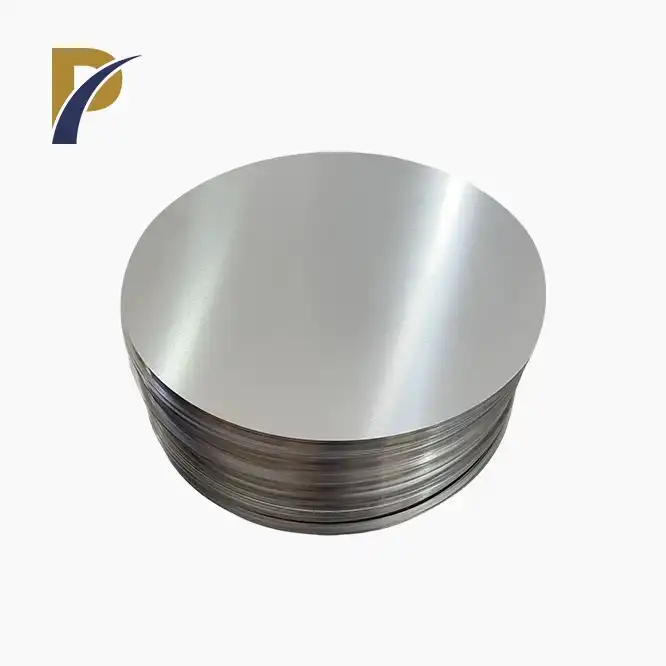

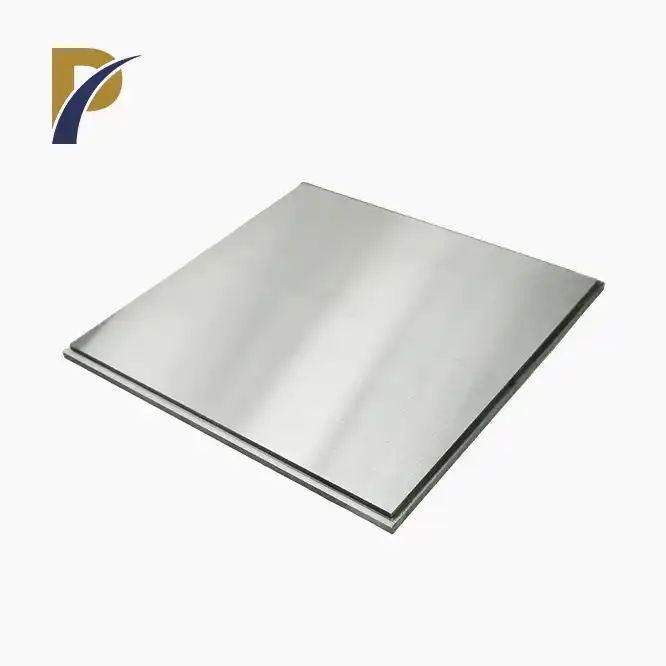

molybdenum plates

Grade: Mo1,TZM,Mo-La,Mo-W Alloy

Purity: 99.95%, 99.97%

Density: 10.2g/cm3

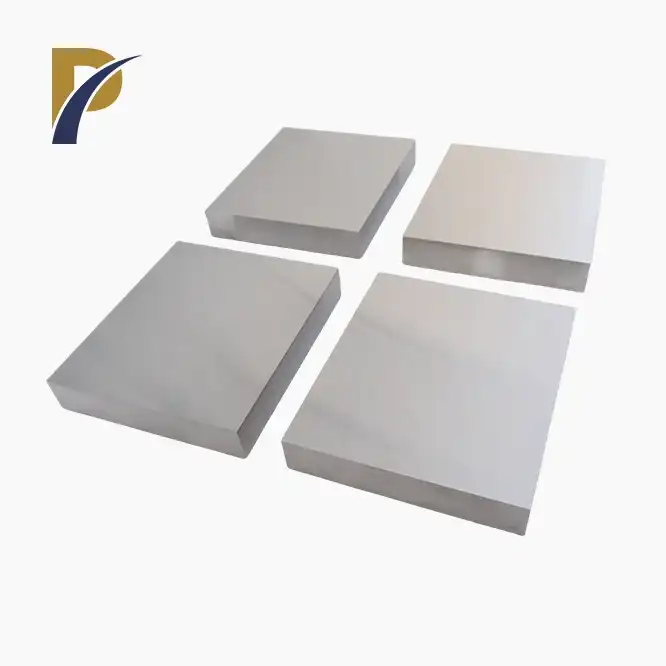

Thickness: 0.2~20mm

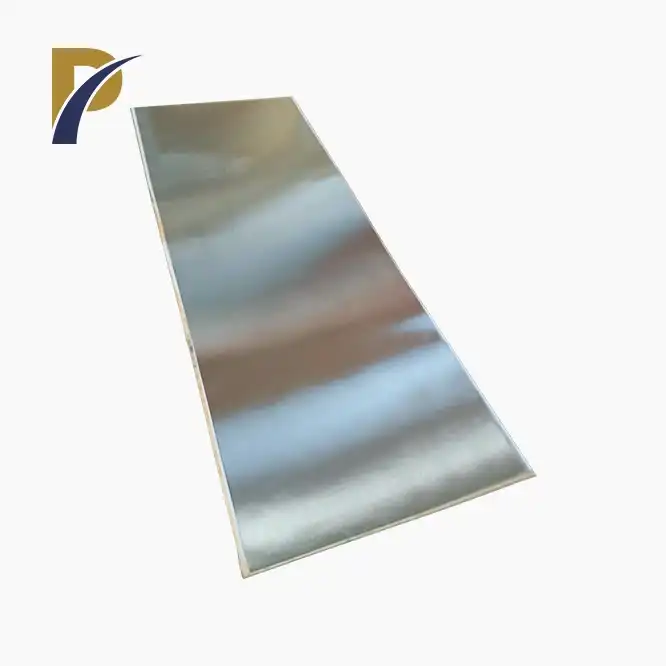

Width: 10~700mm

Length: <2500mm

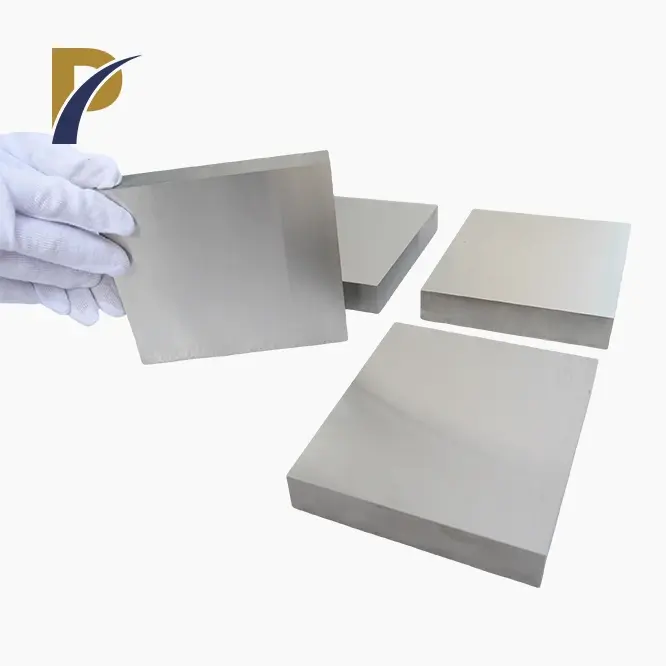

Surface: Bright,polished,Alkaline Washing

Standard: ASTM B386

Application: specialty steels. Molybdenum electrodes, vacuum furnace applications, nuclear power, missiles, and airplane parts.

PRODUCT DESCRIPTION

Molybdenum Plates Introduction

Shaanxi Peakrise Metal Co., Ltd. is proud to offer high-quality molybdenum plates, engineered to meet the rigorous demands of modern industrial and high-tech applications. Our tungsten and molybdenum amalgam bars are fastidiously built to give extraordinary execution. Tungsten, known for its tall dissolving point and thickness, is frequently alloyed with molybdenum to upgrade its mechanical properties.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Molybdenum |

| Purity | 99.95% |

| Density | 10.28 g/cm³ |

| Melting Point | 2623°C |

| Thermal Conductivity | 138 W/m·K |

| Tensile Strength | 350 MPa |

| Hardness | 200 HV |

| Young's Modulus | 330 GPa |

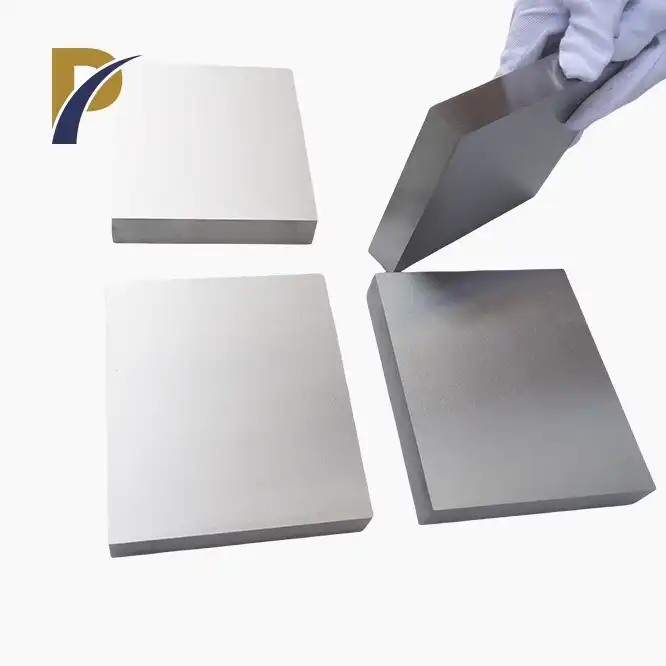

| Thickness Range | 0.5 mm to 50 mm |

| Plate Size | Customizable |

These properties enable our product to excel in high-temperature environments and applications requiring both strength and heat resistance.

|

|

Molybdenum Plates Functions

High-Temperature Stability: Molybdenum Plates can withstand temperatures up to 2623°C, making them suitable for use in high-temperature processes such as furnace linings and aerospace components.

Excellent Thermal Conductivity: With a thermal conductivity of 138 W/m·K, these plates efficiently transfer heat, enhancing the performance of electronic devices and other thermal management applications.

Superior Mechanical Strength: The tensile strength of 350 MPa ensures that the plates remain stable and reliable under mechanical stress, making them ideal for high-load applications.

Corrosion Resistance: Molybdenum's natural resistance to corrosion extends the life of the plates in challenging environments, including chemical processing and high-moisture settings.

Molybdenum Plates Applications

Aerospace Industry: The molybdenum plates are used in aircraft and spacecraft components where high temperature and mechanical strength are critical. Applications include engine parts, heat shields, and thermal protection systems.

Electronics Manufacturing: In electronics, these plates are employed as heat sinks, sputtering targets, and components in high-performance devices due to their excellent thermal conductivity and stability.

Industrial Furnaces: They are utilized in furnace linings and other high-temperature industrial processes where their durability and heat resistance are essential.

Scientific Research: Researchers use it in various experimental setups and high-tech equipment requiring materials that can withstand extreme conditions.

|

|

Production Process

Material Sourcing: We start with high-purity molybdenum powders, ensuring the highest quality for our plates.

Powder Metallurgy: The powders are blended and compacted into desired shapes, followed by sintering in a vacuum furnace to form a solid, dense material.

Plate Formation: The sintered material is rolled or pressed into plates of specified thicknesses and sizes.

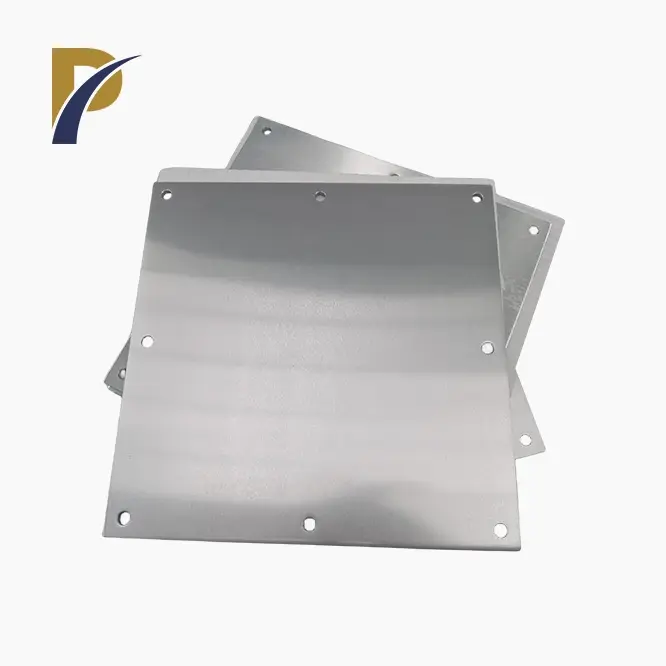

Machining and Finishing: Plates are machined to precise dimensions and surface finishes, tailored to customer requirements.

Quality Control: Each plate undergoes thorough testing and inspection to ensure it meets all quality standards and performance specifications.

|

|

|

Company Overview

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer of non-ferrous metals and alloys, specializing in tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Since 2010, we have focused on expanding our export business, providing high-quality products to international markets.

Our modern production facilities feature advanced equipment, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, and more. This technology allows us to produce precise and reliable the product that meet the highest standards of quality.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging

- Wooden Crates: Ideal for large quantities and heavy plates, ensuring secure and safe transportation.

- Cardboard Boxes: Suitable for smaller quantities, protecting during transit.

- Foam Padding: Used to cushion and protect plates from damage during shipping.

- Waterproof and Moisture-Proof Packaging: Protects plates from environmental factors, ensuring they arrive in perfect condition.

- Custom Packaging: Tailored solutions based on specific customer needs and requirements.

- International Standards: All packaging complies with global shipping and handling regulations.

Logistics

- Sea Freight: Economical for large orders and long-distance shipping.

- Air Freight: Fast delivery for urgent and high-value shipments.

- Land Transport: Efficient for regional distribution and shorter distances.

- Multimodal Transport: Combines various transport methods for optimal logistics solutions.

- Courier Services: Expedited shipping for small or urgent deliveries.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Extensive Experience: Over a decade of expertise in producing and supplying high-quality products.

Advanced Technology: Utilization of state-of-the-art equipment and processes to ensure precision and quality.

Global Reach: Established relationships with customers worldwide, known for reliability and service.

Rigorous Quality Control: Comprehensive testing and inspection to ensure products meet the highest standards.

Customer Focused: Flexible solutions and dedicated support tailored to meet diverse customer needs.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers OEM and ODM services to provide customized High-Temperature Molybdenum Plate tailored to specific applications and requirements. Our team collaborates with clients to deliver products that meet precise specifications and enhance performance.

|

|

FAQ

- What are the products used for? They are used in aerospace, electronics, industrial furnaces, and scientific research where high temperature, mechanical strength, and thermal conductivity are required.

- What are the standard sizes and thicknesses of them? Our plates range from 0.5 mm to 50 mm in thickness and can be customized to various sizes based on customer specifications.

- How are molybdenum plates manufactured? Plates are produced through powder metallurgy, including blending, compacting, sintering, rolling or pressing, and precision machining.

- Can you provide customized the products? Yes, we offer OEM and ODM services to produce customized plates according to specific requirements and applications.

- What quality control measures do you have in place? Each plate undergoes rigorous testing and inspection for density, hardness, thermal conductivity, and other key properties to ensure top quality.

Contact Us

For top-quality molybdenum plates and expert service, reach out to Shaanxi Peakrise Metal Co., Ltd. We are dedicated to providing premium materials and tailored solutions to meet your needs. Contact us today at info@peakrisemetal.com to discuss your requirements and place your order.

YOU MAY LIKE

-

VIEW MOREmolybdenum sheet /plate for heat shield

VIEW MOREmolybdenum sheet /plate for heat shield -

VIEW MORE0.1mm molybdenum sheet /plate

VIEW MORE0.1mm molybdenum sheet /plate -

VIEW MORElanthanated molybdenum plate

VIEW MORElanthanated molybdenum plate -

VIEW MOREmetal molybdenum grinding plate

VIEW MOREmetal molybdenum grinding plate -

VIEW MORErolling molybdenum plate

VIEW MORErolling molybdenum plate -

VIEW MOREpolishing tantalum rod

VIEW MOREpolishing tantalum rod -

VIEW MOREzirconium crucibles

VIEW MOREzirconium crucibles -

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting