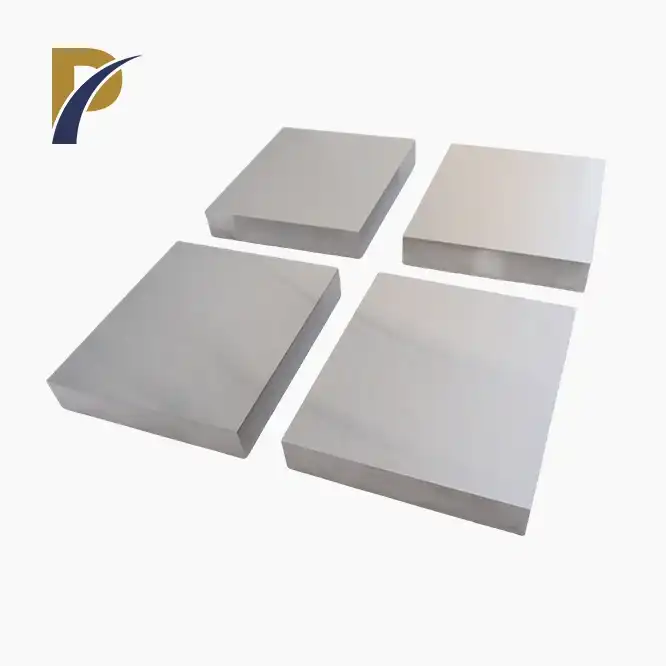

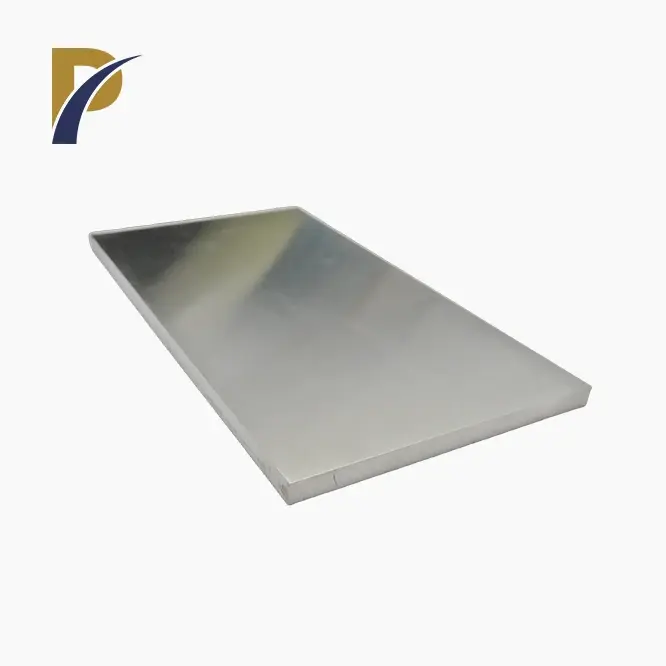

metal molybdenum grinding plate

Grade: Mo1,TZM,Mo-La,Mo-W Alloy

Purity: 99.95%, 99.97%

Density: 10.2g/cm3

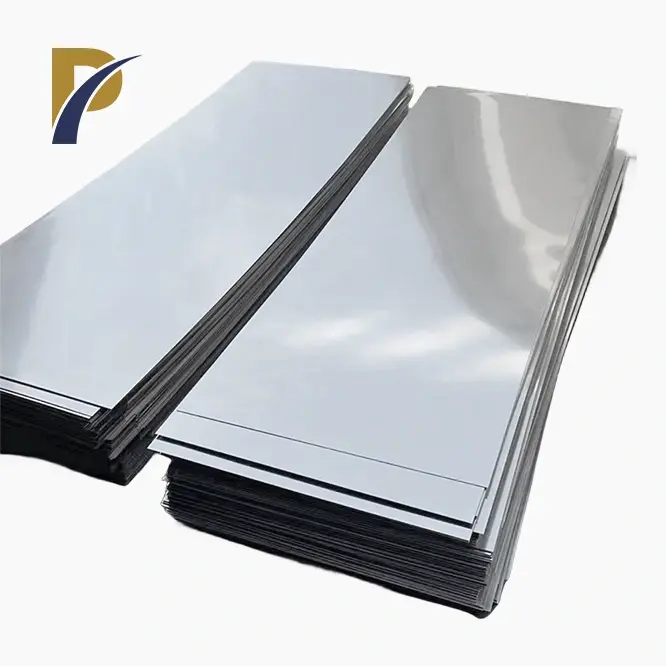

Thickness: 0.2~20mm

Width: 10~700mm

Length: <2500mm

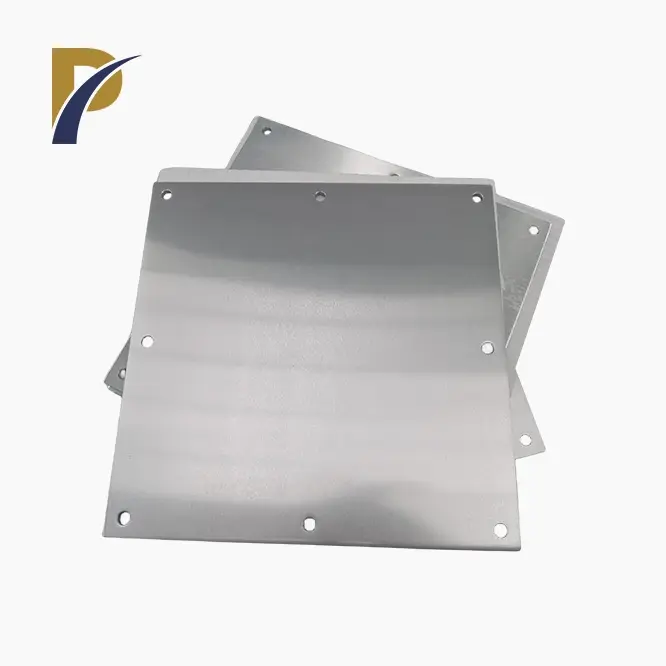

Surface: Bright,polished,Alkaline Washing

Standard: ASTM B386

Application: specialty steels. Molybdenum electrodes, vacuum furnace applications, nuclear power, missiles, and airplane parts.

PRODUCT DESCRIPTION

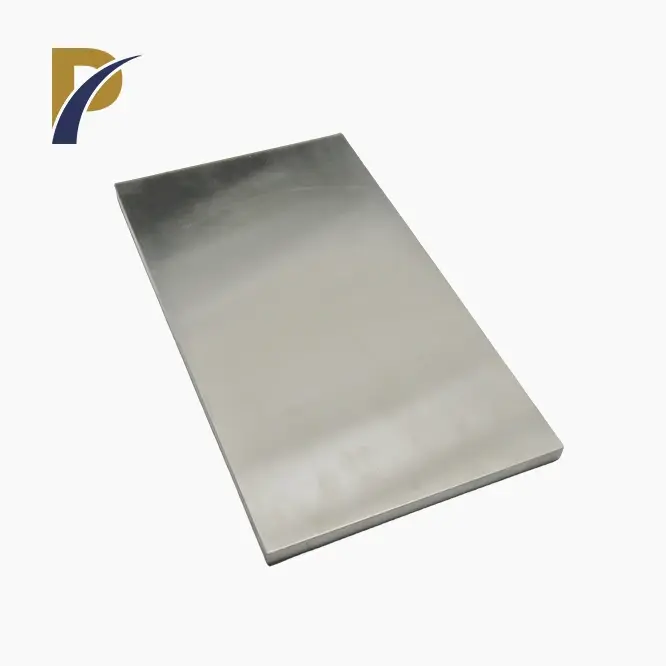

Metal Molybdenum Grinding Plate Product Introduction

The extraordinary hardness, warm conductivity, and protection from wear and consumption of metal molybdenum grinding plate make them a fundamental part in different modern applications.

Our metal molybdenum grinding plate is made with precision and skill, ensuring optimal performance and longevity. Shaanxi Peakrise Metal Co., Ltd., a leading supplier in the industry, is dedicated to delivering high-quality goods supported by our extensive experience and cutting-edge technology.

Product Parameters

| Parameter | Value |

|---|---|

| Density | 10.2 g/cm³ |

| Melting Point | 2623°C |

| Thermal Conductivity | 138 W/m·K |

| Electrical Conductivity | 1.87×10⁷ S/m |

| Hardness | 150 HV |

| Mechanical Property | Value |

|---|---|

| Tensile Strength | 800 MPa |

| Yield Strength | 600 MPa |

| Elongation | 20% |

| Modulus of Elasticity | 320 GPa |

| Poisson's Ratio | 0.31 |

| Chemical Composition | Value |

|---|---|

| Molybdenum (Mo) | ≥ 99.95% |

| Carbon (C) | ≤ 0.01% |

| Oxygen (O) | ≤ 0.02% |

| Nitrogen (N) | ≤ 0.003% |

| Hydrogen (H) | ≤ 0.001% |

|

|

Physical and Chemical Properties

Molybdenum grinding plate are necessary for a variety of industrial applications due to their remarkable chemical and physical properties.

These include:

High Point of Melting: They can withstand high temperatures without losing their structural integrity thanks to its melting point of 2623°C.

Excellent heat conductivity: A thermal conductivity of 138 W/mK ensures efficient heat dissipation for high-temperature applications.

Unrivaled Hardness: The grinding plates' durability and resistance to wear are ensured by a hardness of 150 HV, which extends their lifespan. Excellent conductivity of electricity: These plates are suitable for applications requiring reliable electrical performance due to their electrical conductivity of 1.87107 S/m. Stability in Chemistry: High virtue levels (≥ 99.95% molybdenum) guarantee protection from compound responses, keeping up with security under different circumstances.

|

|

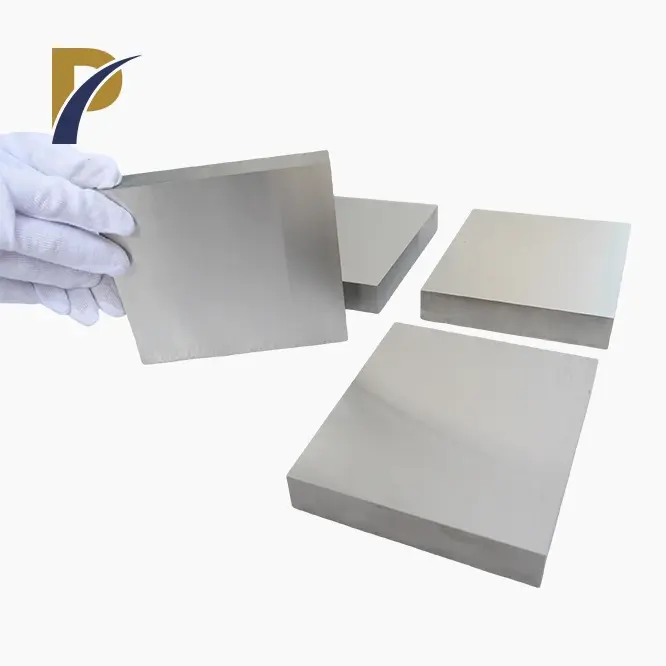

Metal Molybdenum Grinding Plate Functions

Our metal molybdenum grinding plate offer a range of functions, making them highly versatile and valuable in numerous industries. These functions include:

- High-Temperature Resistance: The ability to withstand extreme temperatures without degradation makes these plates ideal for applications in furnaces, aerospace, and power generation.

- Thermal Management: Efficient heat dissipation properties prevent overheating, ensuring the longevity and reliability of equipment in high-temperature environments.

- Wear and Corrosion Resistance: Exceptional hardness and chemical stability protect against wear and corrosion, reducing maintenance costs and downtime.

- Electrical Conductivity: Reliable electrical performance supports applications in electronics and electrical systems.

- Structural Integrity: High tensile and yield strength ensure the plates can endure significant mechanical stress without deforming, enhancing the durability of structures and components.

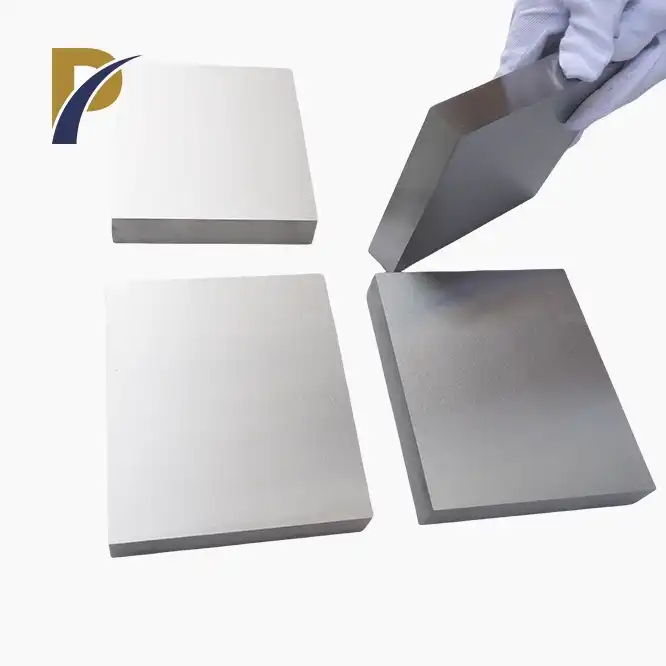

Product Applications

Grinding Molybdenum Plates are valuable in a variety of industries due to their adaptability to a wide range of uses and diverse functions. Key applications include:

Aeronautic trade: utilized in turbine blades and heat shields, high-temperature components that guarantee performance and safety in extreme conditions.

The auto industry: utilized in engine parts and exhaust systems because of their durability and resistance to heat.

Sector of Manufacturing: integral to high-temperature equipment like furnaces and kilns, extending their lifespan and operational effectiveness.

Electrical Systems and Electronics: used in electrical contacts and semiconductor devices to deliver dependable performance over time.

Energy industry: essential due to their resistance to thermal and corrosion in power generation equipment like heat exchangers and reactors.

|

|

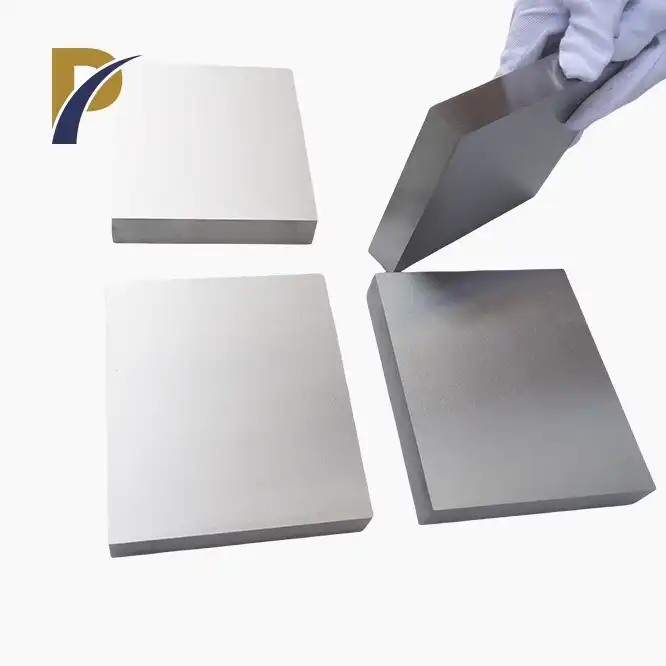

Manufacturing Process

To guarantee superior performance and quality, our Metal Molybdenum Grinding Plate are produced through a series of carefully controlled processes. The procedure entails:

Determination of Unrefined components: Molybdenum of a high virtue is obtained to guarantee the best beginning material.

Powder's Metallurgy: A thick, uniform plate is made by compacting and sintered molybdenum powder.

Rolling and forged: In order to achieve the ideal thickness and mechanical properties, the sintered plates are rolled and manufactured.

Annealing: Vacuum annealing is applied to the plates to reduce internal stresses and improve ductility.

Machining and finishing: In order to meet exact specifications and ensure optimal performance, surface finishing and precision machining are carried out.

|

|

|

Company Introduction

The notable Shaanxi Peakrise Metal Co., Ltd. is acquiring experience in the creation of non-ferrous and stubborn metals.

We have a strong standing as a trustworthy provider to various associations overall because of our long history of giving top notch items.

Since 2010, our primary focus has been on providing high-quality goods and expanding our export business.

Material research, product testing, manufacturing, and stock inventory management are all part of our comprehensive strategy.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging

- Wooden Crates: Sturdy wooden crates provide excellent protection during transportation.

- Carton Boxes: Used for smaller or less fragile items, ensuring safe delivery.

- Foam Padding: Provides cushioning to prevent damage during transit.

- Waterproof and Moisture-Proof Packaging: Protects against environmental factors.

- Custom Packaging: Tailored solutions to meet specific requirements.

- Compliance with International Standards: Ensures packaging meets global shipping regulations.

Logistics

- Sea Freight: Cost-effective for large shipments, offering reliable delivery.

- Air Freight: Fast and efficient for urgent orders.

- Land Transport: Flexible solutions for regional deliveries.

- Multimodal Transport: Combines various modes for optimal efficiency.

- Express Services: Quick and reliable delivery for smaller shipments.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

-

Extensive Knowledge: expertise in non-ferrous and refractory metals for more than a decade.

-

Products of Superior Quality: Superior product standards are guaranteed by rigorous quality control.

-

Services in their entirety: From assembling to Research and development, testing, and stock administration.

-

Global Reach: Through long-term partnerships, products were exported to numerous nations.

-

Advanced Technology: cutting-edge technology and facilities.

-

A focus on the customer: devoted to exceeding customer expectations and meeting them.

-

Advancement and Improvement: Continuous expansion into new technologies and fields.

|

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we support custom processing services to meet the specific needs of our clients. Our OEM/ODM capabilities include:

- Custom Dimensions and Specifications: Tailored to meet unique requirements.

- Special Surface Treatments: Including polishing, coating, and more.

- Precision Machining: Advanced equipment for precise and accurate results.

- Prototyping and Small Batch Production: Flexibility to accommodate various order sizes.

|

|

Frequently Asked Questions (FAQ)

-

What is the delivery time for molybdenum grinding plates?

Delivery times vary based on order size and specifications. Typically, it ranges from 4 to 6 weeks.

-

Can I request custom sizes for molybdenum grinding plates?

Yes, we offer custom dimensions to meet your specific needs.

-

Do you provide samples for testing?

Yes, we can provide samples upon request for testing and evaluation.

Contact Us

Are you looking for high-quality metal molybdenum grinding plate?Shaanxi Peakrise Metal Co., Ltd. is dedicated to providing exceptional solutions tailored to your needs. Reach out to us at info@peakrisemetal.com and discover how we can support your projects with our top-tier products and expertise. Let's work together to achieve excellence!

YOU MAY LIKE

-

VIEW MOREmolybdenum plates

VIEW MOREmolybdenum plates -

VIEW MOREmolybdenum sheet /plate for heat shield

VIEW MOREmolybdenum sheet /plate for heat shield -

VIEW MORE0.1mm molybdenum sheet /plate

VIEW MORE0.1mm molybdenum sheet /plate -

VIEW MORElanthanated molybdenum plate

VIEW MORElanthanated molybdenum plate -

VIEW MORErolling molybdenum plate

VIEW MORErolling molybdenum plate -

VIEW MOREtungsten tantalum alloy plate

VIEW MOREtungsten tantalum alloy plate -

VIEW MOREmolybdenum glass melting electrodes

VIEW MOREmolybdenum glass melting electrodes -

VIEW MOREfine tungsten wire

VIEW MOREfine tungsten wire