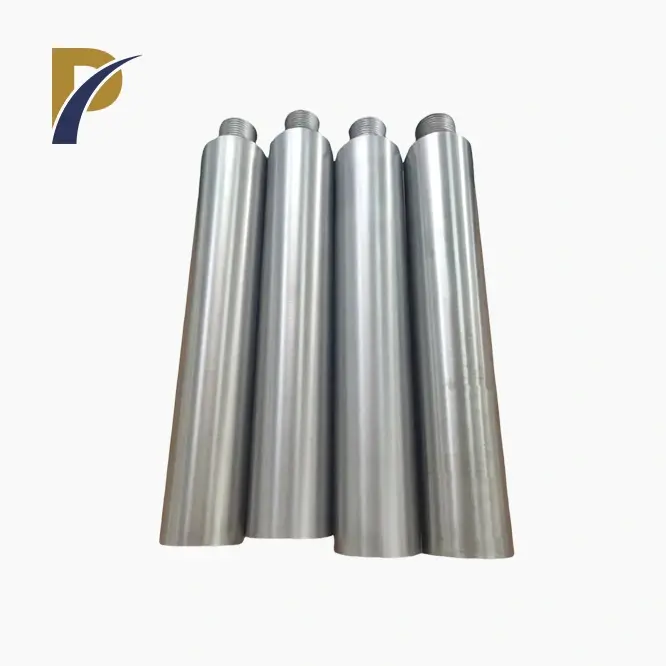

molybdenum glass melting electrodes

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

Introduction To Molybdenum Glass Melting Electrodes

As a reputable leader in the non-ferrous metals industry, we specialize in providing high-quality molybdenum glass melting electrodes for a wide range of industrial applications. To meet the rigid prerequisites of worldwide glass dissolving activities, our molybdenum glass liquefying terminals are fastidiously planned.

Molybdenum electrodes for glass melting are necessary to the process of making glass because of their exceptional electrical and thermal properties. These extremely pure molybdenum electrodes have remarkable heat resistance, allowing them to withstand the high temperatures required for glass melting. This toughness ensures long haul functional soundness, lessening free time and expanding creation effectiveness generally speaking.

Product Specifications

| Property | Value |

|---|---|

| Purity | 99.95% min |

| Density | 10.2 g/cm³ |

| Electrical Conductivity | 31% IACS |

| Tensile Strength | 700 MPa |

| Melting Point | 2,623°C (4,753°F) |

| Thermal Conductivity | 142 W/m·K |

|

|

Physical and Chemical Properties

Molybdenum glass melting electrodes exhibit excellent resistance to heat and corrosion, making them ideal for high-temperature applications such as glass melting and refining processes.

|

|

Molybdenum Glass Melting Electrodes Features

- High Purity: Our molybdenum glass melting electrodes are manufactured to a purity level of 99.95 percent, ensuring that there are few impurities that could compromise performance. For glass melting applications, achieving consistent and dependable results necessitates this high purity.

- High Temperature Resistance: Even in the most demanding operational environments, our electrodes guarantee stability and longevity because they are made to withstand extreme temperatures. For sustained performance during prolonged glass melting processes, this capability is essential.

- Superior conductivity of electricity: Our electrodes facilitate effective energy transfer thanks to their superior electrical conductivity. In order to maintain precise control over the heating and melting processes in glass production and improve overall operational efficiency, this conductivity is essential.

- Excellent Mechanical Strength: Our electrodes have strong mechanical properties that make them extremely strong and long-lasting. This guarantees dependable execution overstretched periods, limiting margin time and streamlining creation yield.

- Stability in Chemistry: Versatile to substance erosion, our cathodes keep up with their honesty and execution trustworthiness in destructive modern settings. This synthetic strength improves unwavering quality and guarantees reliable activity in any event, when presented to unforgiving compound conditions.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Applications

Our glass melting molybdenum electrodes find wide application in:

- Glass industry for melting and refining operations.

- Semiconductor manufacturing for precise thermal management.

- Specialty alloys production due to their high purity and reliability.

|

|

Production Process

Peakrise Metal employs advanced technologies including intermediate frequency sintering furnaces, vacuum arc melting furnaces, and precision machining equipment to ensure the highest quality molybdenum products.

|

|

|

Our Factory

Located in Shaanxi, China, our facility integrates manufacturing, R&D, and quality control to deliver superior non-ferrous metal products globally.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Packaging: We offer wooden crates, cardboard boxes, and custom packaging tailored to international standards for secure transit.

- Shipping: Options include sea freight, air freight, land transportation, multimodal transport, and express delivery services.

Why Choose Us?

- Extensive Experience: Over a decade of expertise in non-ferrous metal production.

- Global Reach: Trusted by customers worldwide including Taiwan, Ukraine, USA, and Germany.

- Quality Assurance: Rigorous testing and quality control ensure products meet the highest standards.

- Customization: We offer OEM/ODM services to tailor products to specific client needs.

|

OEM/ODM Services

|

|

FAQ

-

What is the typical lifespan of your molybdenum electrodes?

- Our electrodes are designed for long-term durability, with a lifespan averaging 500-600 hours of continuous use.

-

Can you customize electrode dimensions?

- Yes, we offer customization services to meet specific dimensional requirements.

-

Are your products environmentally friendly?

- Yes, our molybdenum electrodes are recyclable and comply with environmental standards.

-

Do you provide technical support for product installation?

- Absolutely, our technical team offers comprehensive support throughout the installation process.

-

What are your payment terms and shipping policies?

- We accept various payment methods and offer flexible shipping arrangements to accommodate global clients.

Contact Us

Please contact us at info@peakrisemetal.com to inquire about our molybdenum glass melting electrodes or to discuss your specific requirements. We are eager to collaborate with you.

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes

VIEW MOREmolybdenum electrodes -

VIEW MOREmolybdenum electrodes for glass furnace

VIEW MOREmolybdenum electrodes for glass furnace -

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MORE50 diameter molybdenum elecrtode

VIEW MORE50 diameter molybdenum elecrtode -

VIEW MORE63 diameter molybdenum electrode

VIEW MORE63 diameter molybdenum electrode -

VIEW MOREtungsten evaporation boat

VIEW MOREtungsten evaporation boat -

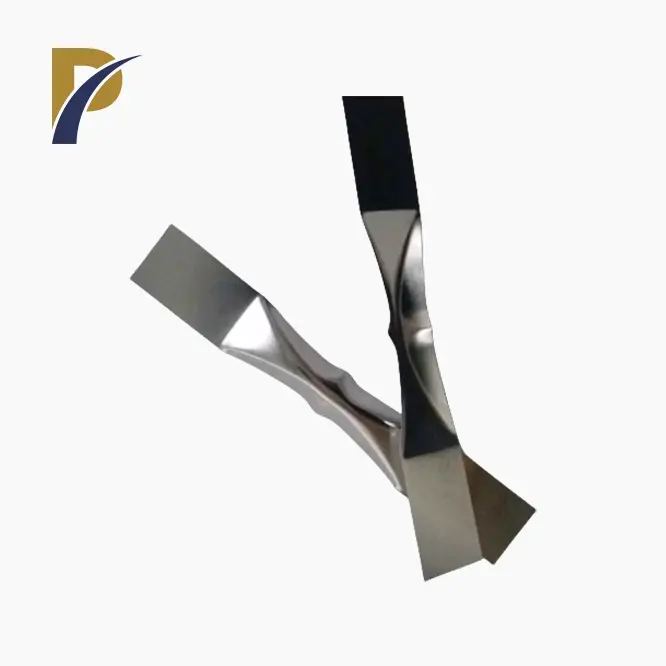

VIEW MOREmolybdenum alloy strip/foil

VIEW MOREmolybdenum alloy strip/foil -

VIEW MOREtungsten crucible for induction furnace

VIEW MOREtungsten crucible for induction furnace