molybdenum electrodes for glass furnace

Purity: 99.97%

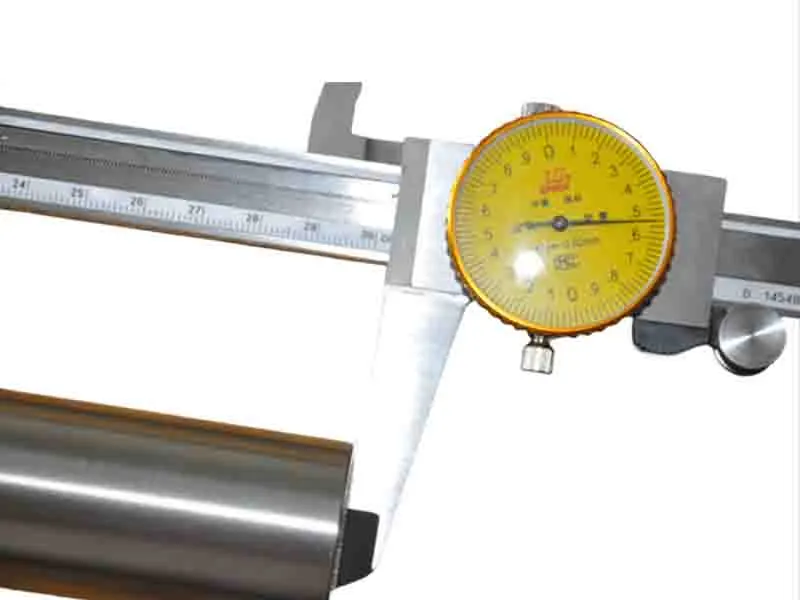

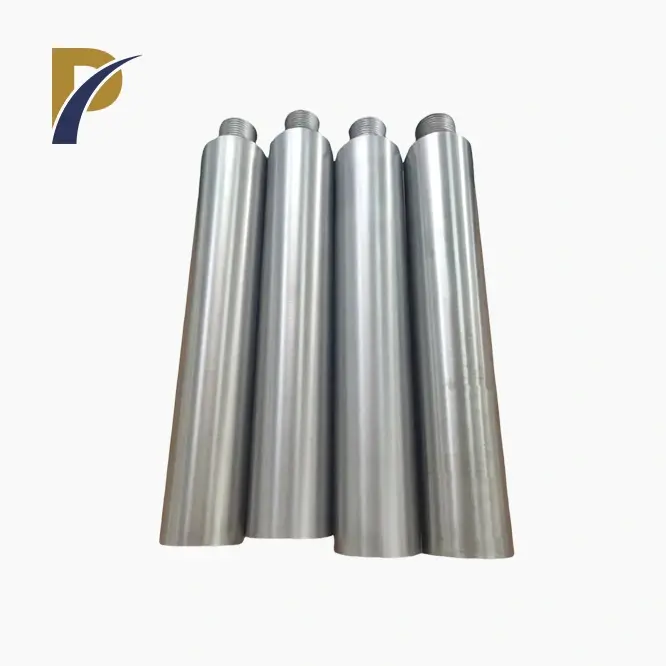

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

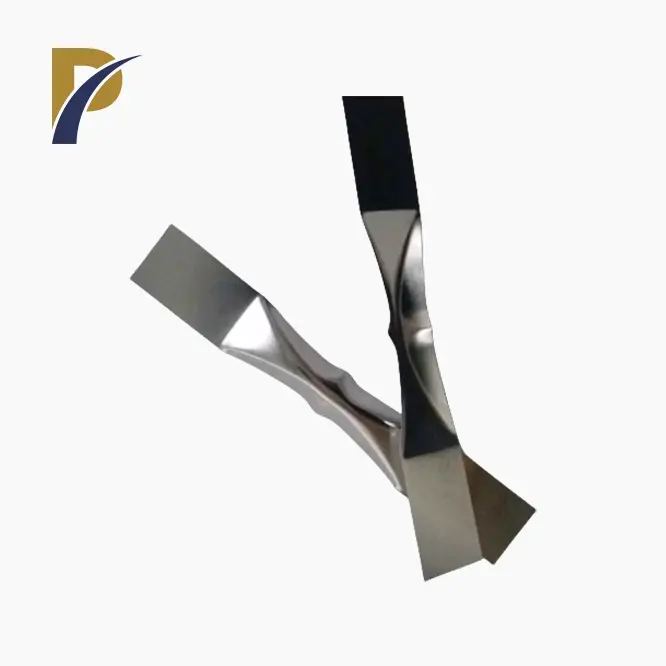

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

Products Introduction

What is molybdenum electrodes for glass furnace?

Molybdenum electrodes for glass furnace is a critical component in the glass manufacturing industry, especially for glass furnaces. These electrodes are renowned for their ability to withstand high temperatures and harsh environments, providing consistent performance and longevity. At Shaanxi Peakrise Metal Co., Ltd., we specialize in producing high-quality molybdenum electrodes tailored specifically for glass furnace applications.

Our molybdenum electrodes are crafted using top-grade materials and advanced manufacturing processes, ensuring superior quality and reliability. As a leading supplier in the industry, Shaanxi Peakrise Metal Co., Ltd. is committed to delivering products that meet the stringent demands of glass manufacturers worldwide. Our extensive experience and dedication to excellence make us a trusted partner for all your molybdenum electrode needs.

Products Specification

molybdenum electrodes for glass furnace are an advanced product, designed with precise chemical composition to ensure optimal performance. Their composition is carefully selected to meet international standards, making them the preferred choice for various applications. The table below succinctly lists their key specifications:

| Parameter | Value |

|---|---|

| Purity | ≥ 99.95% |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Electrical Conductivity | 19.7 MS/m |

| Hardness (HV) | 250-300 |

| Parameter | Value |

|---|---|

| Thermal Conductivity | 138 W/m·K |

| Coefficient of Expansion | 4.8 x 10⁻⁶ /K |

| Elastic Modulus | 329 GPa |

| Tensile Strength | 690 MPa |

| Grain Size | ≤ 100 µm |

| Parameter | Value |

|---|---|

| Specific Heat Capacity | 0.25 J/g·K |

| Flexural Strength | 400 MPa |

| Work Function | 4.2 eV |

| Density | 10.2 g/cm³ |

| Oxygen Content | ≤ 0.005% |

|

|

|

Products physical and chemical properties

Molybdenum electrodes for glass furnace physical and chemical properties

Molybdenum electrodes for glass furnaces possess unique physical and chemical properties that make them ideal for high-temperature applications:

High Melting Point: With a melting point of 2620°C, molybdenum electrodes can withstand the extreme temperatures of glass furnaces without melting or deforming.

Excellent Electrical Conductivity: Ensures efficient transmission of electrical currents, which is crucial for the melting process in glass furnaces.

Low Thermal Expansion: The low coefficient of thermal expansion minimizes dimensional changes under varying temperatures, ensuring stability and precision.

Superior Thermal Conductivity: Facilitates efficient heat transfer, crucial for maintaining uniform temperatures within the furnace.

Corrosion Resistance: Molybdenum electrodes exhibit excellent resistance to corrosion, extending their lifespan even in the harsh chemical environments of glass furnaces.

Products Functions and applications

Molybdenum electrodes for glass furnace functions

Product Functions

Molybdenum electrodes for glass furnaces offer several key functions:

High-Temperature Resistance: Capable of withstanding the extreme temperatures of glass furnaces without degradation, ensuring consistent performance.

Efficient Electrical Conductivity: Provides stable and efficient electrical current transmission, essential for the melting process in glass production.

Thermal Stability: Maintains structural integrity and performance under high thermal stress, reducing the risk of failure or downtime.

Durability and Longevity: The robust nature of molybdenum ensures long-lasting performance, reducing the need for frequent replacements.

Dimensional Precision: Low thermal expansion ensures precise dimensions, critical for maintaining the integrity of the glass melting process.

Molybdenum electrodes for glass furnace applications

Molybdenum electrodes are essential in various applications within the glass manufacturing industry:

Glass Melting Electrodes: Used in the melting process to produce high-quality glass with minimal impurities.

Electrode Holders: Ensures stable and secure placement of electrodes within the furnace.

Heaters and Temperature Sensors: Used in components that require precise temperature control and measurement.

Conductive Elements: Provides reliable electrical conductivity in high-temperature environments.

Production Process and Workflow

Our molybdenum electrodes are produced through a meticulous process to ensure top-notch quality:

Raw Material Selection: High-purity molybdenum powder is selected for optimal performance.

Powder Metallurgy: The molybdenum powder is compacted and sintered at high temperatures to form dense electrodes.

Machining: Precision machining ensures that electrodes meet exact dimensions and tolerances.

Quality Control: Rigorous testing, including chemical analysis and mechanical testing, guarantees product quality.

Surface Treatment: Optional surface treatments enhance the performance and longevity of the electrodes.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is equipped with advanced manufacturing facilities, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, and vacuum annealing furnaces. Our comprehensive range of equipment also includes rolling mills, wire drawing machines, plasma welding rooms, lathes, milling machines, sawing machines, drilling machines, shears, stamping equipment, cutting equipment, grinders, straightening machines, and CNC machines.

With over a decade of experience in non-ferrous metal production, we have built a reputation for quality and innovation. Our products are exported to numerous countries, including Taiwan, Ukraine, South Korea, the United States, Australia, Germany, Iran, and more. We have established long-term relationships with our clients, who recognize and appreciate the quality and reliability of our products.

Packaging and Logistics

Packaging:

Wooden Crates: Durable and secure packaging to protect electrodes during shipping.

Carton Boxes: Lightweight and protective packaging for smaller shipments.

Foam Filling: Added protection against shocks and vibrations.

Waterproof and Moisture-Proof: Specialized packaging to prevent moisture and water damage.

Custom Packaging: Tailored solutions to meet specific customer requirements.

International Standards: All packaging complies with international shipping standards.

Logistics:

Sea Freight: Cost-effective and reliable for large shipments.

Air Freight: Fast and efficient for urgent deliveries.

Land Transport: Flexible solutions for regional deliveries.

Multimodal Transport: Combined transport options for optimized delivery times.

Express Services: Rapid delivery for small and urgent orders.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Extensive Experience: Over a decade of expertise in non-ferrous metal production and export.

High-Quality Products: Commitment to producing products that meet and exceed industry standards.

Advanced Manufacturing Facilities: State-of-the-art equipment and technologies ensure precision and quality.

Global Reach: Established long-term relationships with customers in over ten countries.

Comprehensive Services: From material research and development to product testing and stock inventory.

Customer-Centric Approach: Dedicated to providing excellent customer service and customized solutions.

|

|

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer comprehensive OEM/ODM services to meet the specific needs of our customers. Whether you require custom dimensions, specialized coatings, or unique packaging solutions, our team is ready to collaborate with you to deliver tailored products that meet your exact specifications.

Frequently Asked Questions (FAQ)

What is the purity of your molybdenum electrodes?

Our molybdenum electrodes have a purity of ≥ 99.95%, ensuring high performance and reliability.

Can you provide custom sizes for molybdenum electrodes?

Yes, we offer custom sizes and dimensions to meet your specific requirements.

What industries use molybdenum electrodes?

Molybdenum electrodes are primarily used in the glass manufacturing industry but are also applicable in electronics, metallurgy, chemical processing, and medical industries.

How do you ensure the quality of your products?

We have a rigorous quality control process that includes chemical composition analysis, mechanical testing, and dimensional inspection.

What packaging options do you offer?

We offer a range of packaging options, including wooden crates, carton boxes, foam filling, waterproof and moisture-proof packaging, custom packaging, and international standard packaging.

Contact Us

For more information about our high-quality molybdenum electrodes for glass furnaces or to place an order, please contact us at info@peakrisemetal.com. Our team of experts is ready to assist you with all your requirements and provide you with the best solutions for your high-temperature applications. Partner with Shaanxi Peakrise Metal Co., Ltd. today and experience the difference in quality and service.

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes

VIEW MOREmolybdenum electrodes -

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MOREmolybdenum glass melting electrodes

VIEW MOREmolybdenum glass melting electrodes -

VIEW MORE50 diameter molybdenum elecrtode

VIEW MORE50 diameter molybdenum elecrtode -

VIEW MORE63 diameter molybdenum electrode

VIEW MORE63 diameter molybdenum electrode -

VIEW MOREtungsten evaporation boat

VIEW MOREtungsten evaporation boat -

VIEW MOREtantalum seamless pipe tube

VIEW MOREtantalum seamless pipe tube -

VIEW MOREmolybdenum crucibles

VIEW MOREmolybdenum crucibles