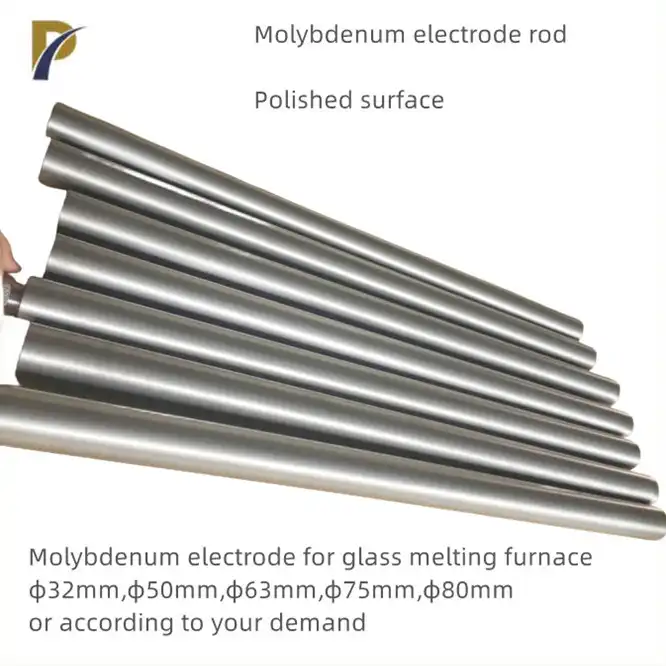

50 diameter molybdenum elecrtode

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

Introduction To 50 Diameter Molybdenum Elecrtode

Welcome to Shaanxi Peakrise Metal Co., Ltd., your go-to source for high-quality 50 diameter molybdenum elecrtode. We excel at producing meticulously engineered electrodes that precisely meet the stringent requirements of various global industries due to our extensive background in manufacturing non-ferrous metals.

Our 50mm molybdenum electrode are designed to improve your processes and contribute to improved operational excellence, whether you need them for glass melting, semiconductor production, or other specialized applications.

Product Parameters

| Parameter | Value |

|---|---|

| Diameter | 50 mm |

| Length | Customizable |

| Purity | 99.95% |

| Density | 10.2 g/cm³ |

| Melting Point | 2,623°C (4,753°F) |

| Thermal Conductivity | 142 W/m·K |

|

|

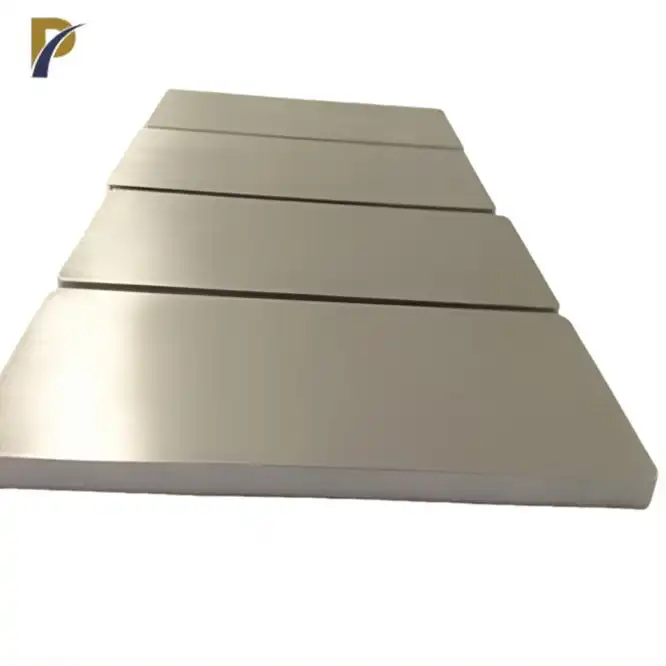

Physical and Chemical Properties

Our 50 diameter molybdenum elecrtode exhibit exceptional thermal and electrical conductivity, coupled with a high melting point, making them ideal for applications requiring robust performance in extreme conditions.

|

|

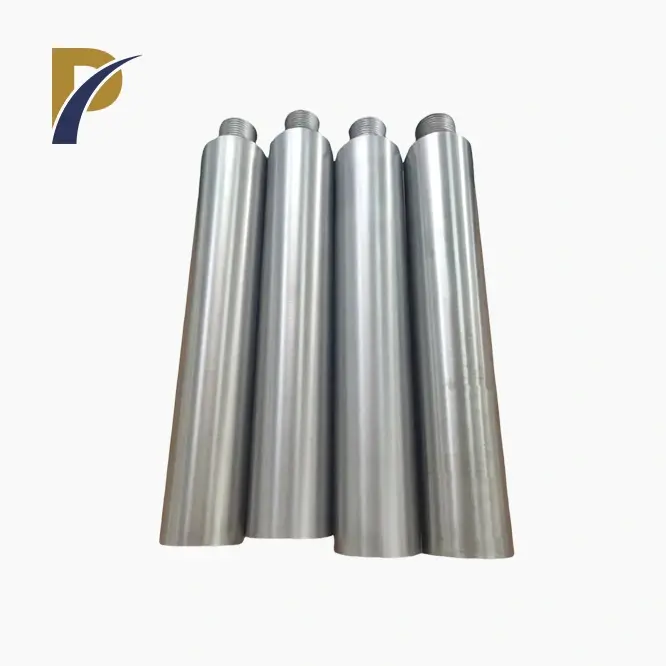

50 Diameter Molybdenum Elecrtode Features

- High Purity: High-purity diameter 50 molybdenum electrodes is used to craft each electrode, ensuring exceptional reliability and performance in critical applications. The electrode's effectiveness and longevity are enhanced under a variety of operating conditions thanks to the purity of our materials.

- Excellent Stability in the Heat: Even in the most demanding thermal environments, our electrodes, which are designed to thrive in extreme temperatures, maintain structural integrity and performance consistency. In high-heat processes like glass melting and semiconductor manufacturing, this capability not only ensures reliable operation but also extends the electrodes' operational lifespan.

- Superior conductivity of electricity: With prevalent electrical conductivity properties, our terminals empower productive energy move all through modern cycles. This trademark is urgent for accomplishing exact control and ideal execution in applications where electrical conductivity is central.

- Customizable Dimensions: We offer customizable dimensions that are tailored to specific requirements because we are aware of the various requirements of our clients. Whether you want anodes for standard applications or extraordinary designs, our adaptable assembling capacities guarantee that every terminal meets your accurate details with accuracy and dependability.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- Semiconductor Industry: Crucial for ion implantation processes.

- Glass and Ceramics: 50 diameter molybdenum elecrtode is used in furnace electrodes for melting and forming.

- Thin Film Deposition: Essential for coating applications in electronics.

- Heating Elements: Provides durable solutions for high-temperature furnaces.

|

|

Production Process

At Shaanxi Peakrise Metal Co., Ltd., each electrode undergoes rigorous manufacturing processes including intermediate frequency sintering and vacuum annealing to ensure optimal purity and performance.

|

|

|

Our Factory

Equipped with state-of-the-art facilities , for example, vacuum bend dissolving heaters and CNC machining focuses, we keep up with elevated requirements of creation and quality control.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Packaging: We offer wooden crates, cardboard boxes, and custom packaging solutions to ensure safe transit.

- Shipping: We provide sea, air, land, multimodal transportation, and expedited delivery options to meet global shipping needs.

Why Choose Us?

Shaanxi Peakrise Metal Co., Ltd. stands out with:

- Extensive Industry Experience

- Commitment to Quality and Innovation

- Global Distribution Network

- Customization Capabilities

- Excellent Customer Support

|

OEM Services

We specialize in OEM services, collaborating closely with clients to meet their unique specifications and requirements.

|

|

FAQ

- What is the typical lead time for orders?

- Lead times vary based on order specifics but are generally competitive.

- Can you provide certificates of compliance?

- Yes, we offer certificates ensuring product quality and specifications.

- Do you offer technical support for product applications?

- Absolutely, our team provides comprehensive technical assistance.

- Are samples available for testing purposes?

- Yes, we offer samples for evaluation upon request.

- What are your payment terms?

- Payment terms are negotiable based on the order size and customer relationship.

Call to Action

Reach us today at info@peakrisemetal.com to examine how our 50 diameter molybdenum elecrtode can help your tasks. For dependable quality and superior service, choose Shaanxi Peakrise Metal Co., Ltd. as your partner.

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes

VIEW MOREmolybdenum electrodes -

VIEW MOREmolybdenum electrodes for glass furnace

VIEW MOREmolybdenum electrodes for glass furnace -

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MOREmolybdenum glass melting electrodes

VIEW MOREmolybdenum glass melting electrodes -

VIEW MORE63 diameter molybdenum electrode

VIEW MORE63 diameter molybdenum electrode -

VIEW MOREelectric furnace sic heating element

VIEW MOREelectric furnace sic heating element -

VIEW MOREcopper tungsten plate

VIEW MOREcopper tungsten plate -

VIEW MOREpure tantalum sheet/plate

VIEW MOREpure tantalum sheet/plate