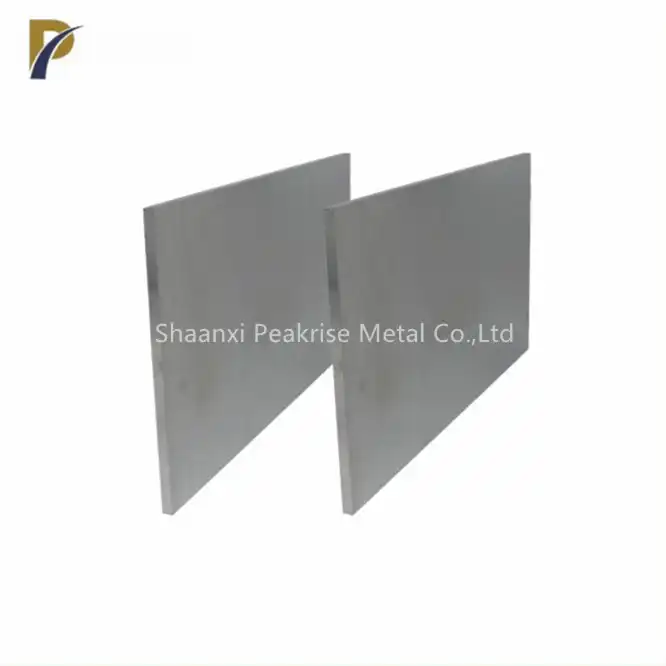

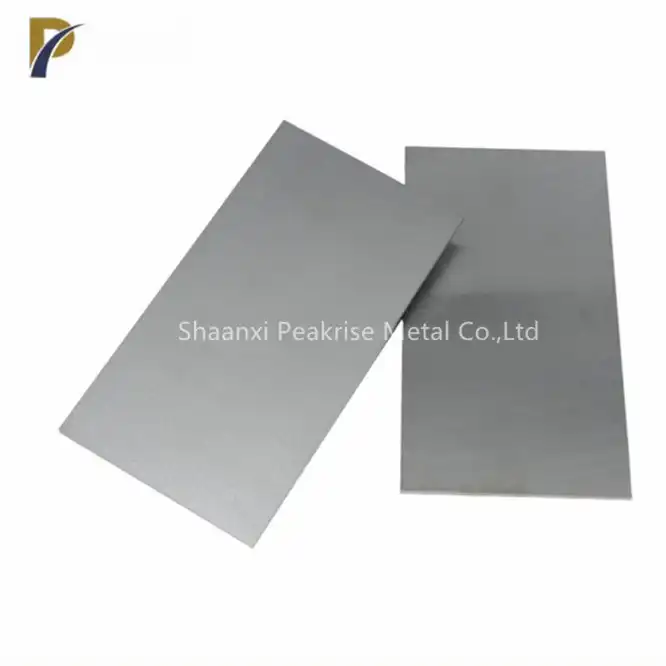

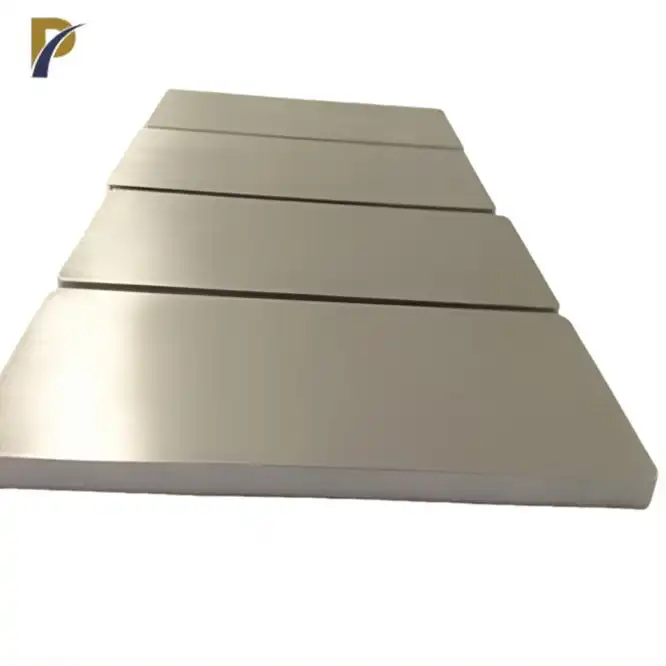

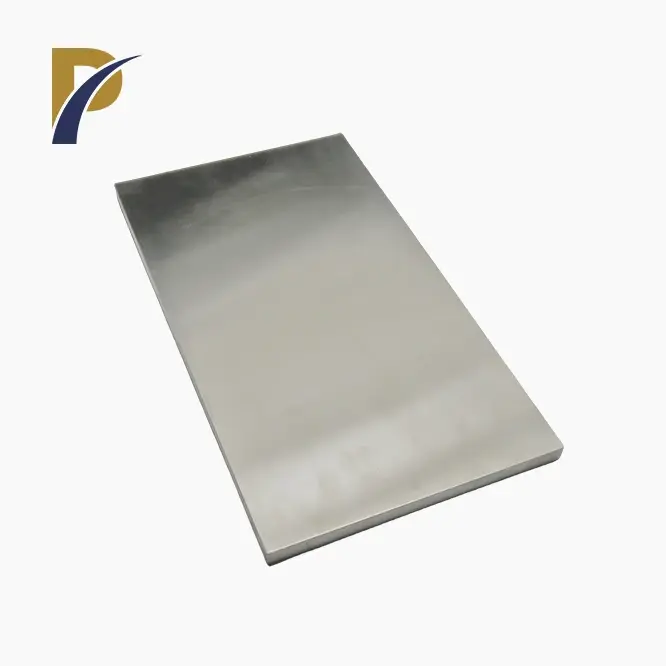

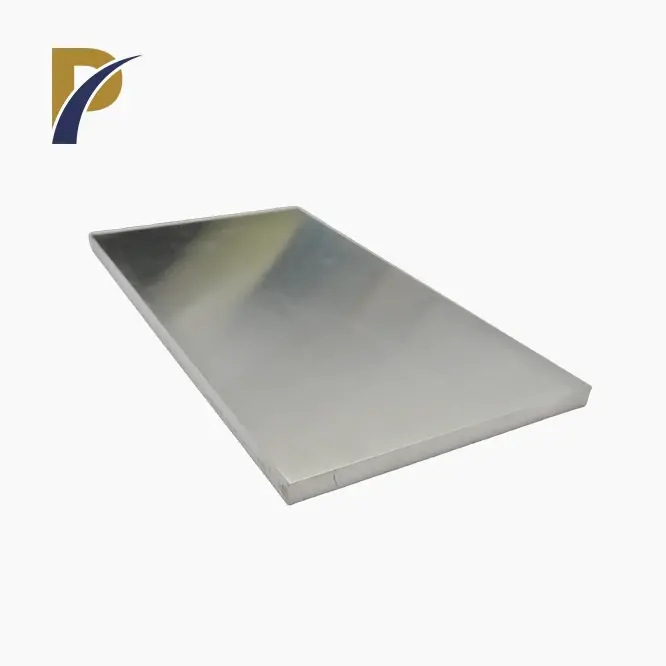

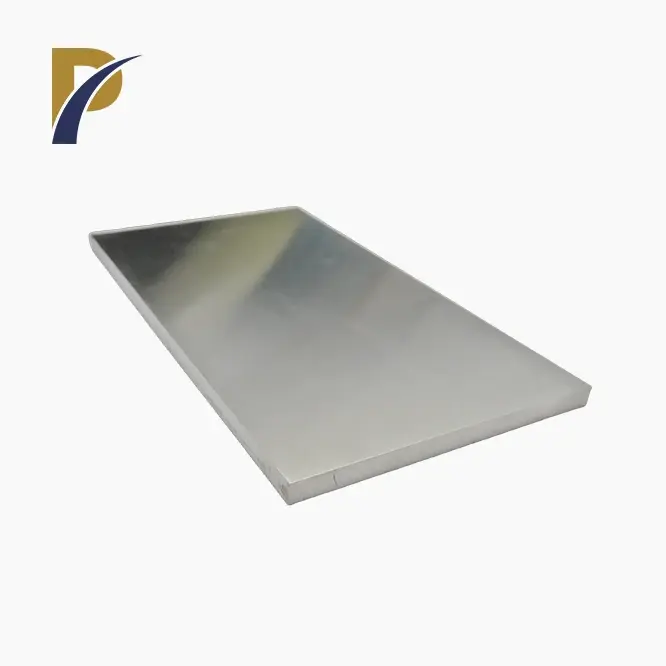

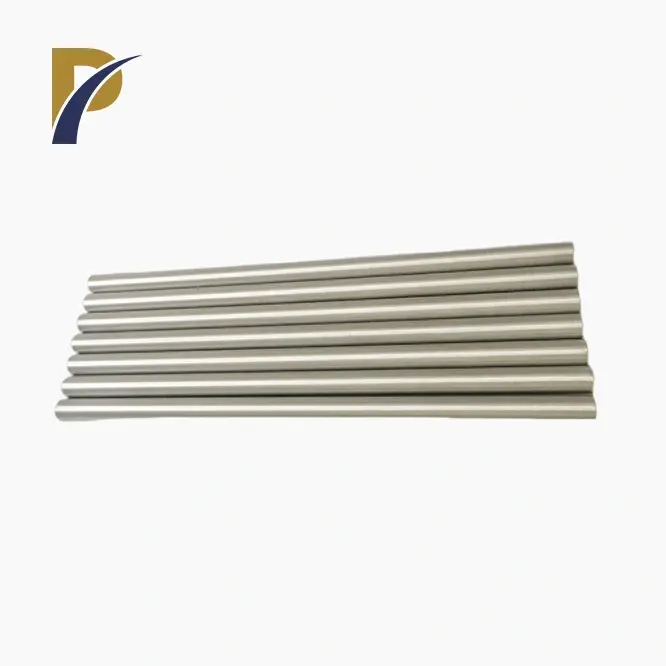

pure tantalum sheet/plate

Material: Tantalum/Tantalum Alloy

Purity : 99.95%,99.99%

Density: ≥16.67g/cm3

Thickness: 0.03~50mm

Standard: ASTM B708

Quality: Third Party Test Report

Type: Manufacturer

Standard: RO5200,RO5252,RO5255

Delivery status: Annealed (M)

PRODUCT DESCRIPTION

Pure Tantalum Sheet/Plate Introduction

As a leading supplier in the non-ferrous metals industry, Peakrise Metal specializes in providing high-quality pure tantalum sheet/plate that meet stringent international standards. Tantalum, renowned for its exceptional corrosion resistance and high melting point, is widely sought after in various industrial applications for its unique properties.

Product Specifications

| Property | Value |

|---|---|

| Purity | 99.95% min |

| Thickness Range | 0.1 mm - 5.0 mm |

| Width | Up to 600 mm |

| Length | Up to 2000 mm |

| Surface | Cold rolled, annealed |

| Density | 16.6 g/cm³ |

| Tensile Strength | 300 MPa min |

| Elongation | 20% min |

| Standard | ASTM B708-98 |

|

|

Physical and Chemical Properties

Pure tantalum exhibits excellent resistance to corrosion by acids and is comparable to glass in its resistance to attack by alkalis.

|

|

Pure Tantalum Sheet/Plate Features

- High Purity: Consistently achieves 99.95% purity to meet the most demanding applications.

- Superior Mechanical Properties: Offers high strength and ductility even at elevated temperatures.

- Excellent Corrosion Resistance: Ideal for use in corrosive environments, including chemical processing and electronics.

- Biocompatibility: Suitable for medical implants and devices.

- Ease of Fabrication: pure tantalum sheet/plate can be easily machined, formed, and welded.

Applications

High-purity tantalum wire finds extensive use in:

- Chemical Processing: Due to its resistance to corrosive chemicals.

- Electronics: Capacitors, semiconductor devices.

- Medical: Surgical implants, prosthetic devices.

- Aerospace: High-temperature applications.

- Energy: Nuclear reactors, turbine blades.

|

|

Manufacturing Process

The manufacturing process refers to the series of steps and activities involved in converting raw materials into finished products. This process typically includes several key stages, each of which contributes to the overall efficiency, quality, and cost-effectiveness of production. Here are the fundamental aspects of a typical manufacturing process:

Design and Planning: Before manufacturing begins, product designs are finalized, and production planning is conducted. This phase involves determining materials, production methods, equipment requirements, and scheduling to optimize efficiency and meet quality standards.

Material Procurement: Raw materials and components required for production are sourced and acquired from suppliers. Manufacturers ensure that materials meet specifications regarding quality, quantity, and compatibility with production processes.

Processing and Assembly: Depending on the product type, manufacturing processes may involve various methods such as machining, molding, casting, forming, welding, or assembly. Each step is carefully executed to transform raw materials into components and then into the final pure tantalum sheet/plate.

Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that products meet predefined standards and specifications. This includes inspections, testing, and verification of dimensions, functionality, and performance.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates state-of-the-art facilities equipped with advanced machinery such as intermediate frequency sintering furnaces, laser cutters, and CNC equipment to guarantee high-quality production standards.

Packaging

Our products are meticulously packaged to ensure:

- Wooden Crates

- Cardboard Boxes

- Foam Cushioning

- Customized Packaging

- Moisture-Proof and Waterproof Packing

All packaging adheres to international standards to safeguard the integrity of the tantalum sheets/plates during transit.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Industry Experience: Over a decade of expertise in non-ferrous metal production.

- Global Reach: Trusted supplier with a presence in markets worldwide.

- Customization: Tailored solutions to meet specific customer requirements.

- Quality Assurance: Rigorous testing and adherence to international quality standards.

- Customer Satisfaction: Proven track record of client satisfaction and long-term partnerships.

OEM Services

We offer comprehensive OEM/ODM services, accommodating custom requirements for pure tantalum wire products to meet specific application needs.

|

|

Frequently Asked Questions (FAQ)

- What is the typical lead time for pure tantalum sheet/plate orders?

- We maintain sufficient stock for quick turnaround; specifics depend on order size and customization.

- Can you provide certifications for material traceability?

- Yes, all materials are accompanied by certificates of conformity and traceability.

- Do you offer samples for testing purposes?

- Yes, we provide samples upon request to ensure compatibility with your application.

- What are your payment terms?

- Flexible terms are available; details can be discussed based on mutual agreement.

- How do you handle international shipments?

- We utilize reliable shipping partners to ensure prompt and secure delivery globally.

Logistics

We offer flexible shipping options:

- Sea Freight

- Air Freight

- Land Transportation

- Multi-modal Transport

- Express Delivery

|

|

|

|

|

|

|

|

|

|

Contact Us

For inquiries or to discuss your pure tantalum sheet/plate requirements, please contact us at info@peakrisemetal.com. We look forward to collaborating with you.

This comprehensive product page not only showcases the technical details and applications of products but also emphasizes Shaanxi Peakrise Metal Co., Ltd.'s commitment to quality, customization, and customer satisfaction in the global market.

YOU MAY LIKE

-

VIEW MOREtungsten tantalum alloy plate

VIEW MOREtungsten tantalum alloy plate -

VIEW MOREmolybdenum lanthanum furnace boats

VIEW MOREmolybdenum lanthanum furnace boats -

VIEW MOREfine tungsten wire

VIEW MOREfine tungsten wire -

VIEW MOREtungsten and molybdenum alloy rod

VIEW MOREtungsten and molybdenum alloy rod -

VIEW MOREtungsten electrodes

VIEW MOREtungsten electrodes -

VIEW MOREcustomized tantalum sputtering target

VIEW MOREcustomized tantalum sputtering target -

VIEW MOREtungsten molybdenum alloy

VIEW MOREtungsten molybdenum alloy -

VIEW MOREmosi2 heating elements

VIEW MOREmosi2 heating elements