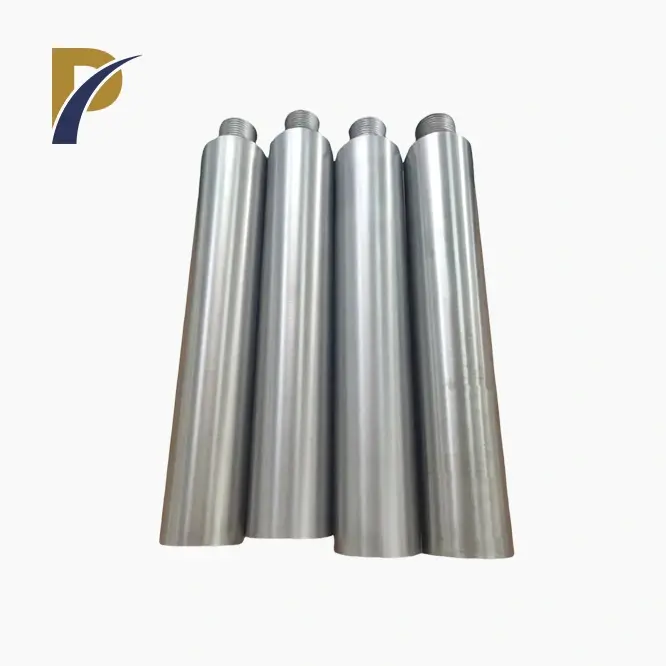

mosi2 heating elements

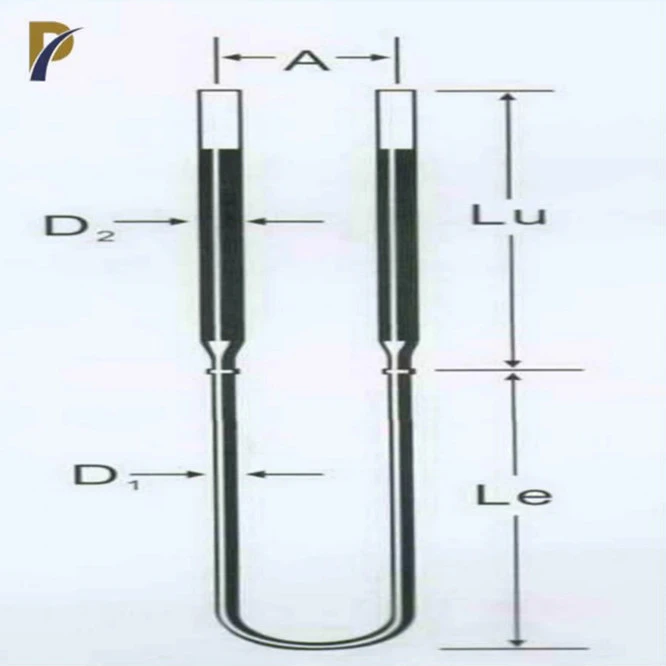

Type: U shape,Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Molybdenum silicide

Size: Φ3/6、Φ4/9、Φ6/12、Φ9/18、Φ12/24 Etc.

Density: 5.6~5.8g/cm3

Use Temperature: 1300~1800℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

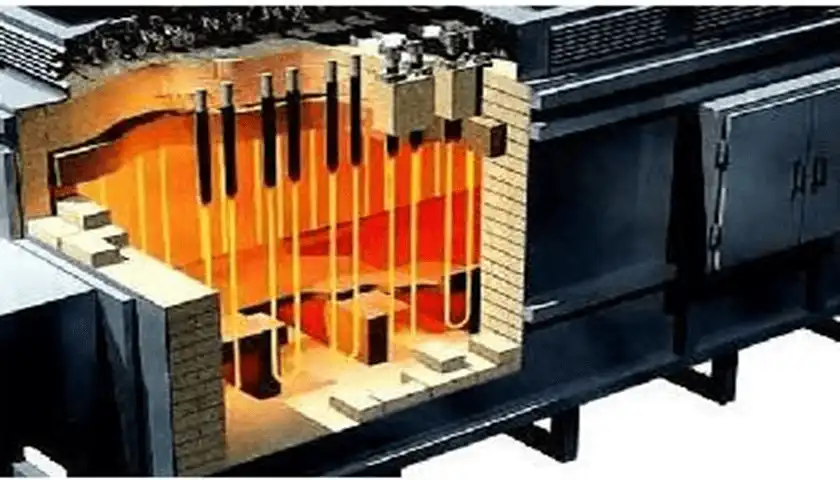

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction

Shaanxi Peakrise Metal Co., Ltd., a prestigious provider in the field of obstinate metals and high level ceramics, is pleased to introduce our excellent mosi2 heating elements. Molybdenum disilicide (MoSi2) heating elements are a crucial part of a variety of industrial heating processes because of their excellent performance in high-temperature applications. Our MoSi2 warming components are designed to convey unrivaled warm proficiency, dependability, and life span, satisfying the thorough needs of worldwide modern business sectors.

As a main MoSi2 warming components provider, Shaanxi Peakrise Metal Co., Ltd. has utilized long stretches of involvement and high level assembling advances to give solid and proficient arrangements. With an operating temperature range of up to 1800 °C, our elements are ideal for use in high-temperature furnaces and kilns because they are built to withstand extreme temperatures. Our MoSi2 Heater Elements provide unparalleled performance and durability for any high-temperature process, including sintering, heat treatment, or any other.

Product Parameter Table

| Parameter | Value |

|---|---|

| Maximum Operating Temperature | 1800°C |

| Electrical Resistivity | 0.018-0.022 Ω·cm |

| Density | 5.6 g/cm³ |

| Melting Point | 2030°C |

| Thermal Conductivity | 25 W/m·K (at 20°C) |

| Tensile Strength | 150-300 MPa |

| Diameter Range | 3/6, 4/9, 6/12 mm |

| Length Range | 300-1800 mm |

| Resistance Tolerance | ±20% |

|

|

|

Physicochemical Properties

When mosi2 heating elements are exposed to air, a protective SiO2 layer forms on their surface, giving them excellent oxidation resistance and high-temperature strength. This layer forestalls further oxidation and drags out the component's life expectancy. The material's high thermal conductivity facilitates rapid and uniform heat distribution, while its low electrical resistivity ensures effective electrical heating. Furthermore, MoSi2 is chemically inert, preventing corrosion in the majority of environments.

|

|

Product Functions

- Stability at high temperatures: MoSi2 warming components can work at temperatures up to 1800°C, making them reasonable for outrageous intensity applications.

- Oxidation Obstruction: To ensure long-term stability and performance, a protective SiO2 layer forms on the surface to stop further oxidation.

- Low Electrical Resistivity: minimizes energy loss and provides electrical heating that is effective.

- High Warm Conductivity: ensures a quick and even distribution of heat throughout the element.

- Durability: resistant to mechanical wear and thermal shock, ensuring a long service life even in harsh environments.

Product Applications

- Furnaces used in industry: Utilized in high-temperature heaters for sintering, strengthening, and intensity therapy processes.

- Pottery kilns: essential for the production of ceramics because it provides high-temperature heating that is constant.

- Glass Assembling: due to their capacity to maintain stable high temperatures, they are utilized in the melting and processing of glass.

- Metallurgical Cycles: suitable for melting and alloying, among other metallurgical processes.

- Industry of Semiconductors: utilized in the processes of diffusion and oxidation for their precise temperature control capabilities.

|

|

Product Process and Production Flow

- Selection of Raw Materials: High-virtue molybdenum and silicon powders are painstakingly chosen.

- Blending and Shaping: Pressing or extrusion is used to combine the powders and create the desired shapes.

- Sintering: In order to attain the required density and strength, the formed components are sintered in a controlled atmosphere.

- Machining and Wrapping up: To ensure optimal performance, elements are machined to exact dimensions and finished.

- Control of Quality: Thorough testing and assessment are led to guarantee every component fulfills the most elevated guidelines.

|

|

|

Our Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. is an exhaustive non-ferrous metal creation undertaking with almost 10 years of involvement with assembling and handling. We have best in class creation gear, including middle of the road recurrence sintering heaters, vacuum circular segment softening heaters, and laser cutters. Our office is outfitted with cutting edge testing and assessment instruments to guarantee the greatest principles. Our MoSi2 Heater Elements have received high praise from our international customers and are exported all over the world, including to the United States, Germany, and South Korea.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

-

Packaging:

- Crates of wood: robust and safe packaging to shield the goods from the elements during transport.

- Cardboard Boxes: options for lightweight, cost-effective packaging.

- Froth Cushioning: Guarantees the components are padded and safeguarded from shocks.

- Packaging that is impervious to water and moisture: protects the elements from harm to the environment.

- Custom Bundling: made in accordance with international standards and specific customer requirements.

-

Logistics:

- Ocean Cargo: a cost-effective choice for large shipments.

- Airship cargo: Rapid and dependable for last-minute deliveries.

- Transport by Land: Adaptable and effective for local deliveries

- Transport by Multiple Modes: Consolidating various methods of transportation for ideal effectiveness.

- Service for Couriers: pertaining to smaller, urgent shipments.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Extensive Knowledge: Over a decade of non-ferrous metal industry experience.

- Products of Superior Quality: determination to provide products that meet the highest standards.

- Modern manufacturing: the most recent technology and equipment.

- Global Reach: Products that were exported to a lot of well-known nations worldwide.

- Customer-Centric: Concentrate on satisfying customer requirements and offering exceptional service.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers complete OEM/ODM administrations, taking into account tweaked creation to meet explicit client prerequisites. Our accomplished group works intimately with clients to foster customized arrangements, guaranteeing the most significant level of fulfillment and execution.

|

|

FAQ

-

What is the maximum operating temperature of MoSi2 heating elements?

- The maximum operating temperature is 1800°C.

-

How do MoSi2 heating elements resist oxidation?

- They form a protective SiO2 layer on the surface, which prevents further oxidation.

-

Can MoSi2 heating elements be used in a vacuum?

- Yes, they are suitable for use in vacuum environments.

-

What are the standard dimensions available?

- Diameters range from 3/6 to 6/12 mm, and lengths range from 300 to 1800 mm.

-

Do you offer custom sizes and shapes?

- Yes, we provide customized solutions to meet specific requirements.

Contact Us

Are you looking for high-temperature mosi2 heating elements that are both dependable and effective? Shaanxi Peakrise Metal Co., Ltd. is here to furnish you with top-quality items and outstanding help. Contact us right away at info@peakrisemetal.com to discuss your requirements and learn how we can assist you in achieving your objectives. We should fabricate a fruitful organization together!