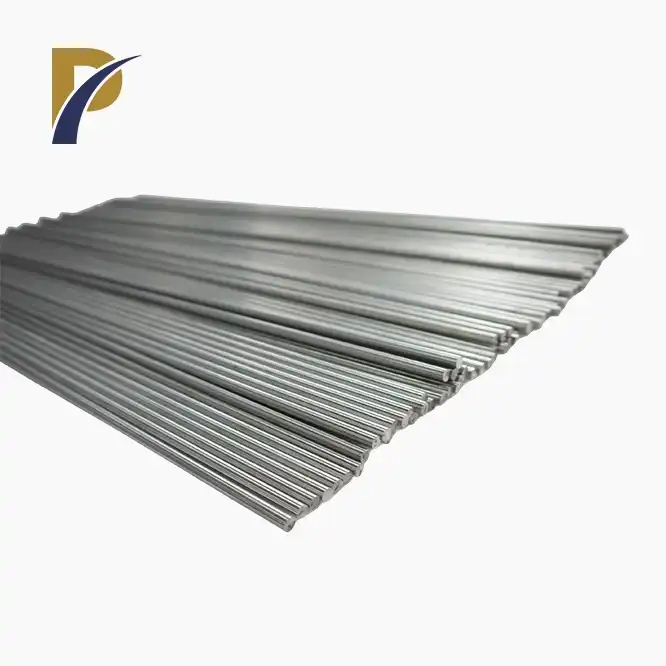

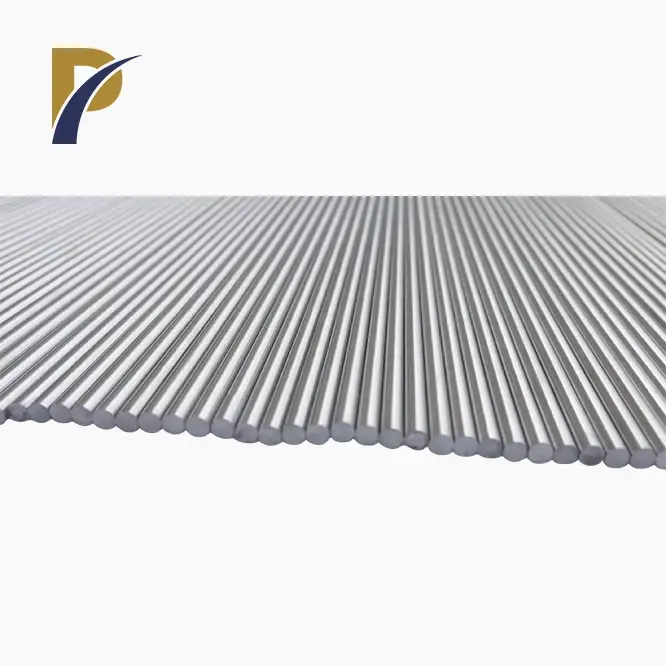

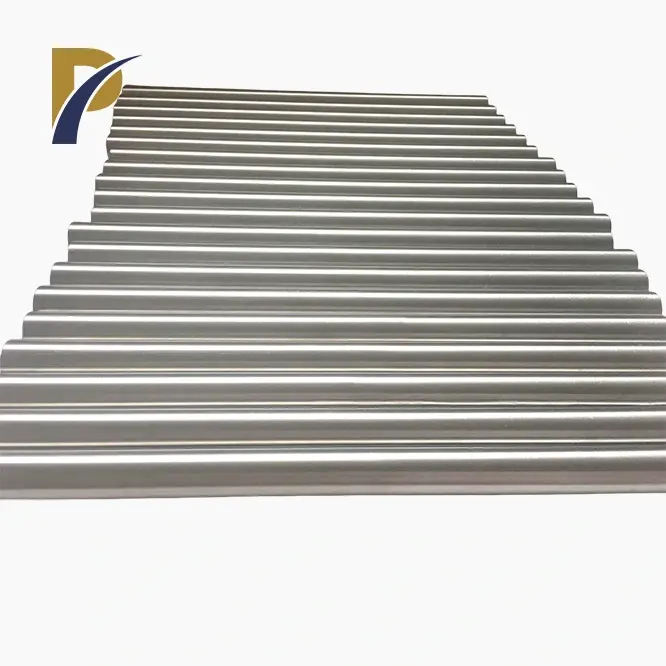

tungsten and molybdenum alloy rod

W Content: 25%,30%,50% (wt%)

Diameter: 3-150mm

Length: <2000mm

Shape: Rod

Advantage: Excellent Electrical Conductivity

Surface: Bright

Work Temperature:>1800℃

Standard: ASTM B387

Package: Plywood case

PRODUCT DESCRIPTION

Tungsten and Molybdenum Alloy Rod Product Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of high-quality tungsten and molybdenum alloy rod. Our tungsten and molybdenum amalgam bars are fastidiously built to give extraordinary execution. Tungsten, known for its tall dissolving point and thickness, is frequently alloyed with molybdenum to upgrade its mechanical properties. This combination comes about in a fabric that is unimaginably strong and flexible, appropriate for a wide run of high-temperature applications. At Shaanxi Peakrise Metal Co., Ltd., we are committed to conveying items that not as it were meet but surpass industry standards.

As a conspicuous provider of tungsten and molybdenum amalgam poles, we take pride in our broad encounter and ability. Our state-of-the-art fabricating offices and thorough quality control forms guarantee that each item we convey is of the most elevated quality.

Product Specifications

Below are the detailed parameters of our Molybdenum Tungsten Rod presented in three tables, ensuring you have all the accurate and essential data at your fingertips.

| Parameter | Value |

|---|---|

| Diameter Range | 1.0 - 100.0 mm |

| Length Range | 50 - 2000 mm |

| Density | 17.0 - 19.3 g/cm³ |

| Melting Point | 2620 - 3420°C |

| Tensile Strength | 800 - 1000 MPa |

| Purity | ≥99.95% |

Chemical Composition

| Element | Composition (%) |

|---|---|

| Tungsten (W) | 70 - 90 |

| Molybdenum (Mo) | 10 - 30 |

| Impurities | ≤0.05 |

Physical Properties

| Property | Value |

|---|---|

| Electrical Resistivity | 5.5 - 8.0 µΩ·cm |

| Thermal Conductivity | 130 - 170 W/m·K |

| Coefficient of Thermal Expansion | 4.8 - 6.2 µm/m·K |

|

|

|

Tungsten and Molybdenum Alloy Rod Functions

Our products are designed to serve a variety of functions across different industries. Key functions include:

- High-Temperature Applications: Ideal for use in environments where extreme heat resistance is crucial.

- Thermal Management: Effective in dissipating heat in electronic components and heat sinks.

- Structural Components: Used in aerospace and defense industries for their superior strength-to-weight ratio.

- Corrosion-Resistant Parts: Suitable for chemical processing industries where resistance to corrosive substances is required.

- Electrical Contacts: Excellent for applications requiring reliable electrical conductivity.

Product Applications

The unique properties of our tungsten and molybdenum alloy rod make them indispensable in various applications. These include:

- Aerospace Industry: Used in rocket nozzles, turbine blades, and other high-temperature components.

- Electronics: Essential for heat sinks, circuit boards, and other electronic components.

- Medical Devices: Utilized in medical imaging equipment and radiation shielding.

- Chemical Processing: Employed in reactors and vessels where corrosion resistance is critical.

- Defense: Integral in the manufacturing of armor-piercing projectiles and other military hardware.

|

|

Manufacturing Process

At Shaanxi Peakrise Metal Co., Ltd., we employ advanced manufacturing processes to ensure the highest quality of our product. The production process includes:

- Powder Metallurgy: High-purity tungsten and molybdenum powders are blended and compacted.

- Sintering: The compacted powders are sintered at high temperatures to form solid rods.

- Rolling and Forging: The sintered rods are further processed to achieve the desired dimensions and mechanical properties.

- Machining: Precision machining ensures the rods meet exact specifications.

- Quality Control: Rigorous testing and inspection guarantee the rods' quality and performance.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts a state-of-the-art manufacturing facility equipped with cutting-edge machinery. Our facility includes:

- Intermediate frequency sintering furnace

- Vacuum arc melting furnace

- Laser cutter

- Plasma electron beam melting furnace

- Vacuum annealing furnace

- Rolling mills, wire drawing machines, and other advanced equipment

Our highly skilled team of engineers and technicians ensures that every product meets the highest standards of quality and performance.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

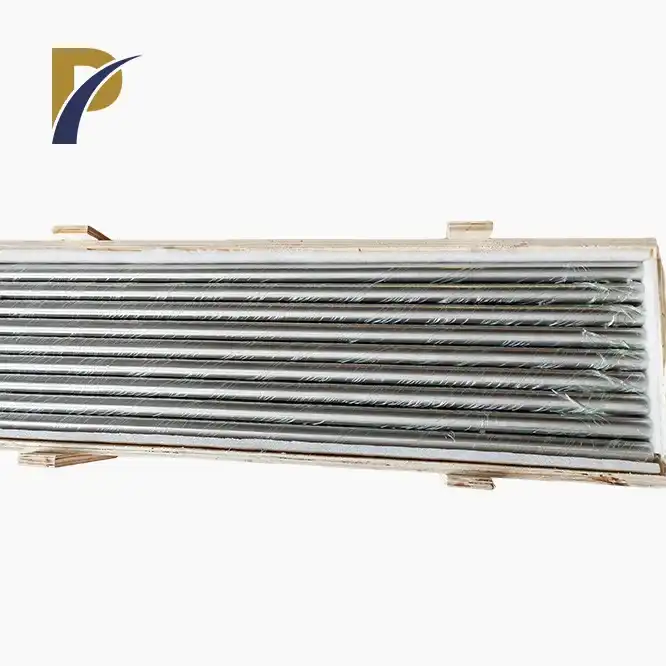

Packaging and Logistics

We understand the importance of secure and efficient packaging and logistics. Our packaging options include:

- Wooden crates

- Cardboard boxes

- Foam inserts for added protection

- Waterproof and moisture-proof packaging

- Custom packaging to meet specific requirements

- All packaging meets international standards

For logistics, we offer:

- Sea freight

- Air freight

- Land transportation

- Multimodal transport

- Express delivery services

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Choosing Shaanxi Peakrise Metal Co., Ltd. means benefiting from our extensive experience and commitment to quality. Our advantages include:

- Over a decade of expertise in non-ferrous metal production

- Comprehensive product range with over 100 types of alloys

- State-of-the-art manufacturing and testing facilities

- High-quality standards and rigorous quality control

- Strong global presence with products exported to numerous countries

- Long-term partnerships with international clients

- Dedication to customer satisfaction and continuous improvement

|

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. is proud to offer OEM and ODM services. We give tweaked answers to meet your particular necessities, guaranteeing that our tungsten and molybdenum compound poles are customized to your accurate prerequisites. To deliver products that meet your requirements and industry standards, our team collaborates closely with you.

|

|

Frequently Asked Questions (FAQ)

-

What are the main uses of the Tungsten and Molybdenum Alloy Rod?

- They are primarily used in high-temperature applications, thermal management, and as structural components in aerospace and defense industries.

-

Can you provide custom sizes and specifications?

- Yes, we offer OEM services and can customize the rods to meet your specific requirements.

-

What is the typical lead time for an order?

- Lead times vary based on order size and specifications but generally range from 4 to 8 weeks.

Contact Us

Ready to take your projects to the next level with high-quality tungsten and molybdenum alloy rod?

Contact Shaanxi Peakrise Metal Co., Ltd. today. Our team is here to provide you with the best solutions and support. Reach out to us at info@peakrisemetal.com and let us help you achieve your goals.