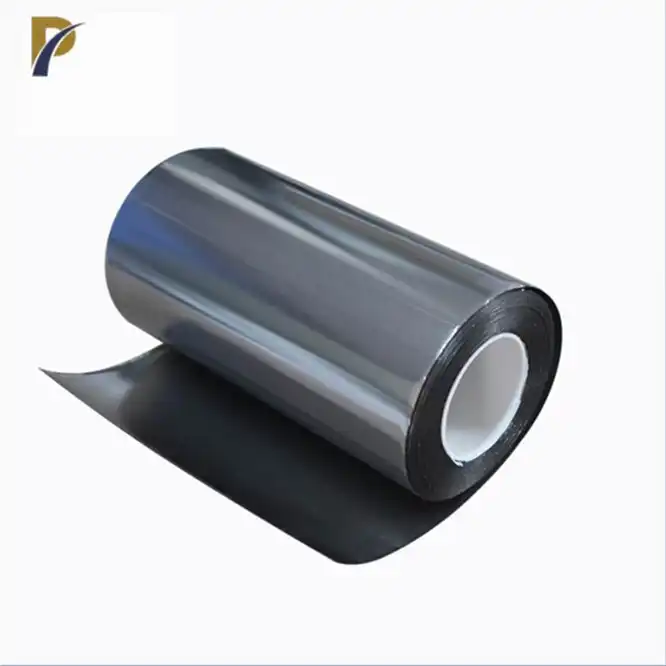

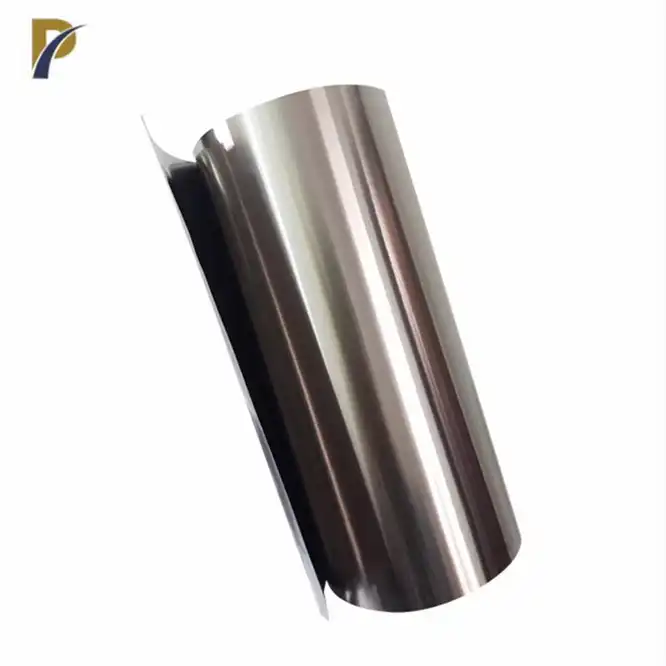

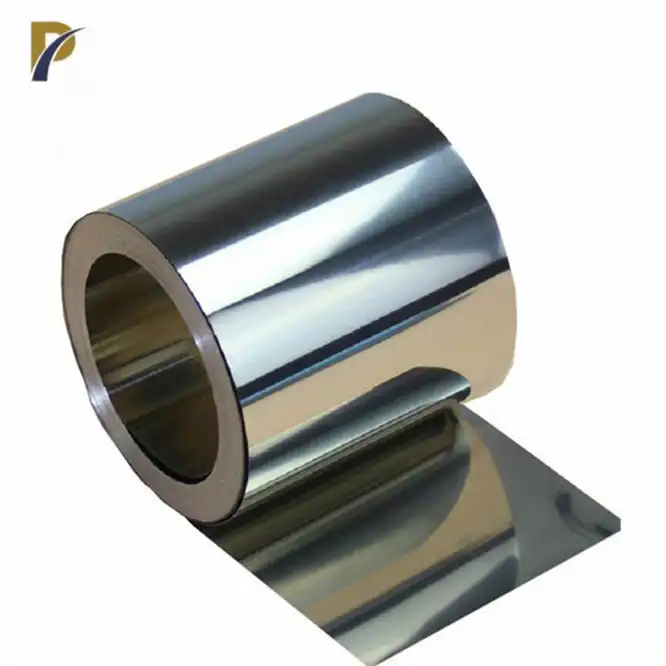

pure titanium foil

Material: Titanium & Titanium alloy

Grade: GR1,GR2,GR5,GR7,GR9,GR12

Thickness: 0.01-0.5mm

Width:20-500mm

Shape: rolled

Surface: bright

Standard: ASTM B265

Process: cold rolling

Application: Petrochemicals/Aerospace/Electronics/Precision Manufacturing/Military Industry/Scientific

Research/Medical and other special materials

PRODUCT DESCRIPTION

Pure Titanium Foil Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., a leading supplier of pure titanium foil renowned for its exceptional quality and performance in various industrial applications. With extensive expertise in the production of non-ferrous metals, Peakrise Metal delivers high-quality titanium products tailored to meet global market demands.

Product Specifications

| Property | Value |

|---|---|

| Thickness | 0.025 mm |

| Width | 300 mm |

| Length | Customizable |

| Purity | 99.5% min |

| Surface | Smooth, without defects |

| Tensile Strength | 350 MPa |

| Elongation (%) | 25% |

| Standard | ASTM B265, AMS 4911 |

|

|

Physical and Chemical Properties

The Pure Titanium Foil exhibits excellent corrosion resistance, high strength-to-weight ratio, and superb formability. It is non-magnetic and biocompatible, making it ideal for a wide range of applications.

|

|

Product Features

- Corrosion Resistance: Resistant to corrosion in marine and chemical environments.

- High Strength: High-purity pure titanium foil is suitable for weight-sensitive applications.

- Formability: Easily formable into various shapes and sizes without compromising structural integrity.

- Biocompatibility: Safe for medical implants and surgical instruments.

- Heat Resistance: Maintains integrity at elevated temperatures up to 600°C.

Applications

The product finds extensive use in:

- Medical Devices: The pure titanium foil is widely used in medical implants and devices due to its biocompatibility and non-toxic nature. It is used in surgical instruments, orthopedic implants such as plates and screws, dental implants, and cardiovascular devices like stents. Its ability to integrate with bone tissue without adverse reactions makes it a preferred material in medical applications.

- Aerospace: The product's lightweight nature and high strength-to-weight ratio make it ideal for aerospace applications. It is used in aircraft components such as airframes, engine components, and structural parts where durability and resistance to high temperatures and corrosive environments are essential. Its low density helps reduce overall weight, contributing to fuel efficiency and performance.

- Electronics: In electronics, it is used in various capacitors, especially those requiring stable electrical performance over a wide range of temperatures. Its corrosion resistance ensures long-term reliability in electronic components exposed to harsh environments or moisture.

- Chemical Processing:It is employed in chemical processing industries where resistance to corrosion from acids, alkalis, and saltwater is critical. It is used in equipment such as heat exchangers, tanks, and valves where durability and resistance to chemical reactions are required to maintain operational efficiency and safety.

- Sporting Goods: It is increasingly used in sporting goods due to its strength, lightweight, and corrosion resistance properties. It can be found in high-performance bicycles, golf clubs, tennis rackets, and even in camping equipment such as lightweight cookware and tent poles.

- Art and Architecture: Architects and artists appreciate the pure titanium foil for its aesthetic appeal and ability to withstand outdoor conditions without rusting or tarnishing. It is used in sculpture, building facades, and interior design elements where a durable, low-maintenance material is desired.

- Marine Applications: Its resistance to saltwater corrosion makes it valuable in marine applications. It is used in boat components, underwater structures, and offshore platforms where exposure to seawater and harsh marine environments would degrade other metals over time.

- Automotive Industry: In automotive engineering, it is used in exhaust systems, where its high temperature resistance and corrosion resistance to exhaust gases and road salts are crucial. It contributes to improved durability and longevity of exhaust components.

|

|

Production Process

Our manufacturing process involves advanced equipment including vacuum arc melting furnaces and precision rolling mills to ensure stringent quality control and precise specifications.

|

|

|

Why Choose Us?

At Shaanxi Peakrise Metal Co., Ltd., we distinguish ourselves with:

- Extensive Experience: Over a decade in non-ferrous metal production.

- Advanced Facilities: State-of-the-art equipment for precise manufacturing.

- Global Reach: Trusted by customers worldwide in diverse industries.

- Customization: OEM/ODM services tailored to meet specific client needs.

- Quality Assurance: Compliant with international standards (ISO 9001).

|

Logistics and Packaging

- Packaging: Secure wooden, cardboard, and custom packaging ensuring international standards compliance.

- Logistics: Efficient sea, air, land, and multimodal transportation options, including express delivery services.

|

|

|

|

|

|

|

|

|

|

FAQ

-

What is the typical lead time for orders?

- We maintain a standard lead time of 2-4 weeks, depending on order volume and customization requirements.

-

Can you provide test certificates with the shipment?

- Yes, we include comprehensive test certificates verifying material properties and quality.

-

Is the product recyclable?

- Yes, it is fully recyclable and environmentally friendly.

-

Do you offer samples for testing purposes?

- Yes, we provide samples upon request to ensure product suitability.

-

What are your accepted payment methods?

- We accept T/T, L/C, and other negotiable methods for international transactions.

Contact Us

Ready to explore the superior quality of pure titanium foil? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com. Let’s discuss how we can fulfill your titanium requirements efficiently and reliably.