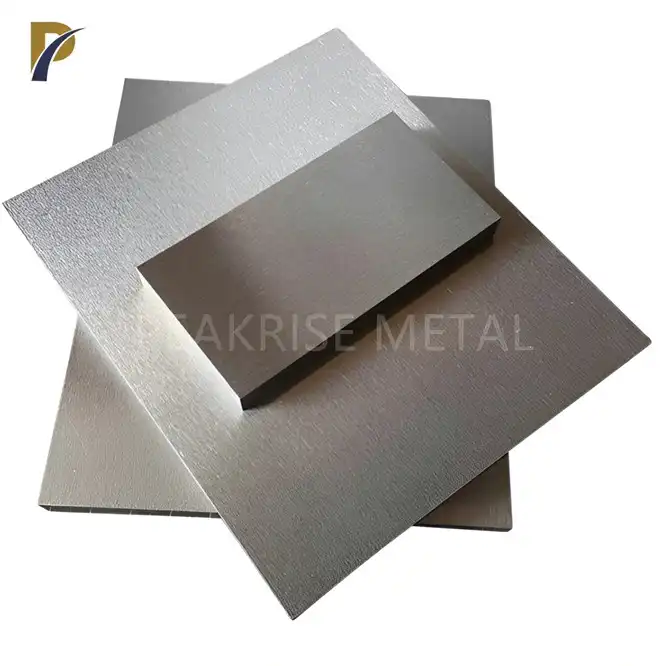

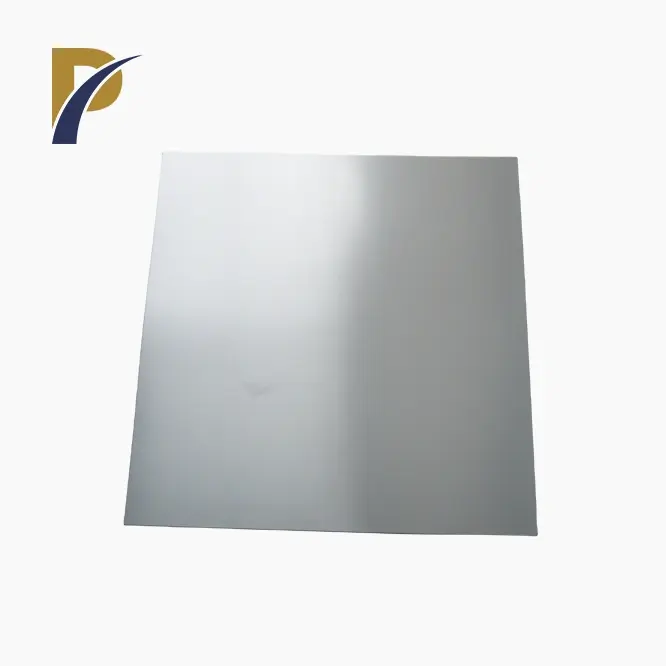

tungsten tantalum alloy plate

Material: Tantalum/Tantalum Alloy

Purity : 99.95%,99.99%

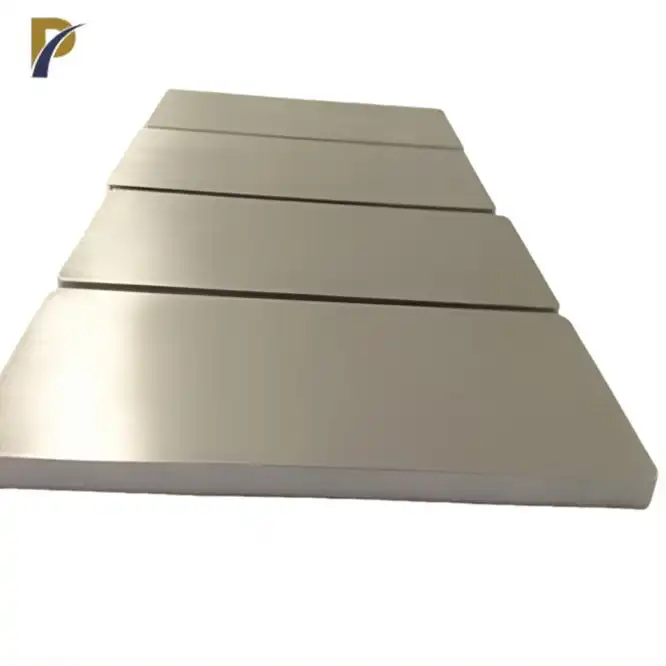

Density: ≥16.67g/cm3

Thickness: 0.03~50mm

Standard: ASTM B708

Quality: Third Party Test Report

Type: Manufacturer

Standard: RO5200,RO5252,RO5255

Delivery status: Annealed (M)

PRODUCT DESCRIPTION

Tungsten Tantalum Alloy Plate Introduction

At Shaanxi Peakrise Metal Co., Ltd, we are proud to offer premium tungsten tantalum alloy plates, designed to meet the rigorous demands of various high-performance applications. Our alloy plates are crafted from a carefully engineered blend of tungsten and tantalum, known for their remarkable properties that are crucial for advanced industrial applications.

Product Parameters

Basic Specifications

| Thickness (mm) | Width (mm) | Length (mm) | Alloy Composition (%) | Density (g/cm³) |

|---|---|---|---|---|

| 1.0 | 100 | 1000 | W-30Ta | 16.9 |

| 3.0 | 200 | 2000 | W-40Ta | 17.0 |

| 5.0 | 300 | 3000 | W-50Ta | 17.1 |

Mechanical Properties

| Property | Value (W-30Ta) | Value (W-40Ta) | Value (W-50Ta) |

|---|---|---|---|

| Tensile Strength (MPa) | 600 | 650 | 700 |

| Yield Strength (MPa) | 300 | 350 | 400 |

| Elongation (%) | 5 | 6 | 4 |

Thermal and Chemical Properties

| Property | Value (W-30Ta) | Value (W-40Ta) | Value (W-50Ta) |

|---|---|---|---|

| Melting Point (°C) | 3200 | 3220 | 3240 |

| Thermal Conductivity (W/m·K) | 170 | 175 | 180 |

| Coefficient of Thermal Expansion (x10⁻⁶/K) | 4.5 | 4.7 | 4.9 |

|

|

Physical and Chemical Properties

Its possess several critical physical and chemical properties:

High Melting Point: The alloy maintains stability under extreme temperatures, suitable for high-temperature applications.

Excellent Corrosion Resistance: The tantalum RO5200 wire component provides superior resistance to corrosion, making it ideal for use in harsh chemical environments.

High Density: Tungsten's high density imparts substantial mechanical strength and durability.

|

|

Product Functions

Temperature Resistance: These plates are designed to perform reliably at high temperatures, making them suitable for applications in aerospace and industrial processes.

Corrosion Resistance: The alloy's resistance to chemical attack ensures longevity in environments exposed to corrosive substances.

Structural Strength: The high density and strength of the alloy make it ideal for structural components that require robustness and durability.

Product Applications

Aerospace Industry: Used in the manufacturing of components exposed to high temperatures and mechanical stress, such as rocket nozzles and aerospace structures.

Defense Sector: Ideal for armor plating and other military applications where high durability and resistance to extreme conditions are critical.

Chemical Processing: Employed in reactors and other equipment handling aggressive chemicals due to its corrosion-resistant properties.

|

|

Manufacturing Process

Material Selection: Tungsten tantalum alloy plates are selected for their superior properties.

Alloy Preparation: The materials are combined in precise ratios using vacuum arc melting to produce the alloy.

Plate Formation: The alloy is then cast into slabs, which are rolled or pressed into plates of desired thickness and size.

Heat Treatment: Plates undergo heat treatment to enhance their mechanical properties.

Inspection and Testing: Each plate is rigorously tested for quality, including checks on dimensional accuracy, mechanical properties, and surface finish.

|

|

|

About Our Factory

Shaanxi Peakrise Metal Co., Ltd is a prominent manufacturer specializing in tungsten, tantalum, and other refractory metals.

Logistics and Packaging

Packaging:

Wooden Crates: Provides robust protection for large or heavy plates during transport.

Cardboard Boxes: Suitable for smaller quantities.

Foam Padding: Protects the plates from damage caused by shock and vibration.

Waterproof Wrapping: Guards against moisture during shipping.

Custom Packaging: Tailored solutions available based on customer requirements.

Logistics:

Sea Freight: Economical option for large shipments, with options for bulk transport.

Air Freight: Fast and reliable for urgent deliveries.

Land Transport: Effective for regional distribution.

Multimodal Transport: Combines various transport methods for efficient delivery.

Courier Services: Ideal for expedited or small orders.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Extensive Expertise: Over a decade of experience in the production of refractory metals.

Advanced Facilities: State-of-the-art equipment and technology for superior product quality.

Global Reach: High-strength tantalum RO5200 wire exported to multiple countries with a strong international presence.

Commitment to Quality: Rigorous testing and quality control to ensure the highest standards.

Customer-Centric Approach: Customized solutions and responsive customer service.

|

OEM Services

We provide comprehensive OEM and ODM services to cater to specific customer needs. Our team is dedicated to working closely with clients to develop customized products that meet precise specifications.

|

|

Frequently Asked Questions

What is the typical lead time for tungsten tantalum alloy plate?

Lead time generally ranges from 6 to 8 weeks, depending on order size and customization.

Can you supply custom sizes and thicknesses for the plates?

Yes, we offer tailored solutions to meet specific requirements.

What are your payment terms?

Payment terms include advance payment or letter of credit.

Do you provide technical support for selecting the right tungsten tantalum alloy plate?

Yes, our technical experts are available to assist with product selection and application.

What shipping options do you offer?

We offer sea, air, land, and courier shipping options.

Contact us

For more information or to place an order for Tungsten Tantalum Alloy Plates, please contact Shaanxi Peakrise Metal Co., Ltd. We look forward to partnering with you to provide high-quality products tailored to your needs.

Email: info@peakrisemetal.com

YOU MAY LIKE

-

VIEW MOREpure tantalum sheet/plate

VIEW MOREpure tantalum sheet/plate -

VIEW MORE63 diameter molybdenum electrode

VIEW MORE63 diameter molybdenum electrode -

VIEW MORElanthanated molybdenum rod

VIEW MORElanthanated molybdenum rod -

VIEW MOREtungsten welding electrodes

VIEW MOREtungsten welding electrodes -

VIEW MORE0.1mm molybdenum sheet /plate

VIEW MORE0.1mm molybdenum sheet /plate -

VIEW MOREheavy metal tungsten alloy

VIEW MOREheavy metal tungsten alloy -

VIEW MOREtungsten crucible for induction furnace

VIEW MOREtungsten crucible for induction furnace -

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator