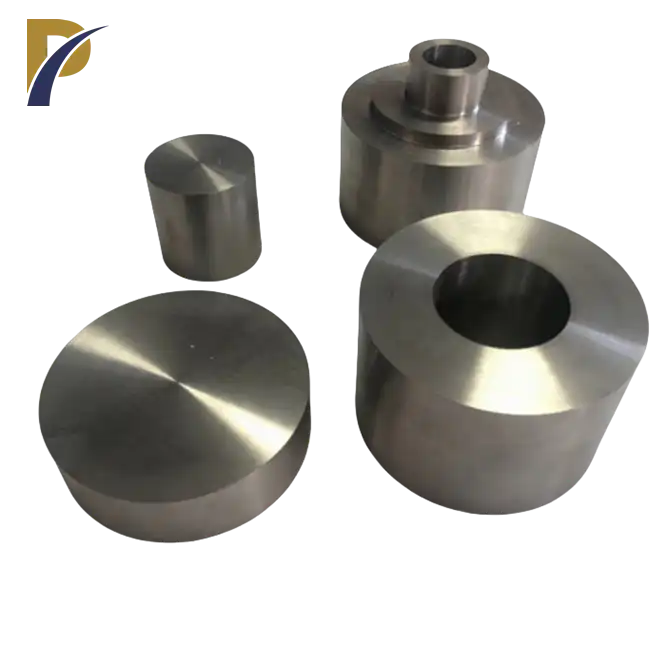

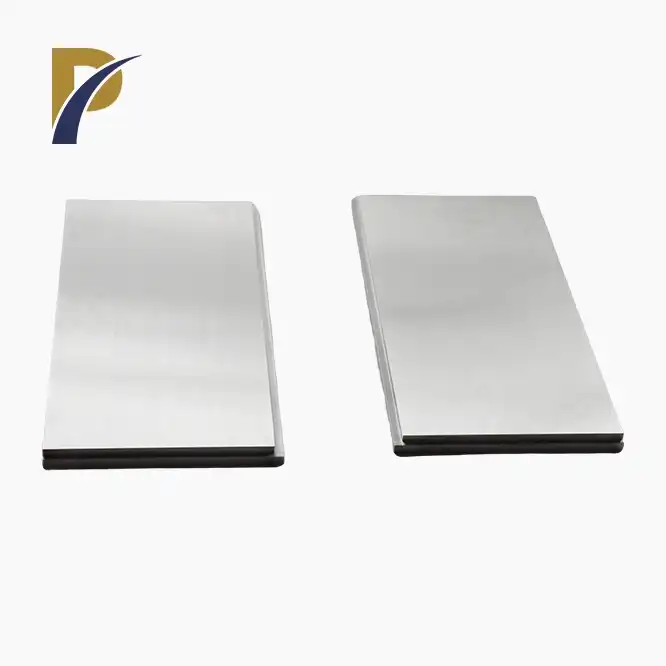

heavy metal tungsten alloy

Material: Tungsten Nickel Copper Alloy

Grade: 90W,92.5W,95W,97W

Elongation: ≥2%

Density: 16.8~18.85g.cm3

Size: According To Customer Drawing

Application: Automotive Industry,Medical Equipment,Aerospace Industry,Sports equipment.

PRODUCT DESCRIPTION

Heavy Metal Tungsten Alloy Introduction

Weighty metal tungsten amalgams are composite materials that consolidate tungsten with different metals like nickel, iron, or copper.

These alloys are known for their exceptional density, high melting points, and excellent mechanical properties, making them indispensable in various industries. Heavy metal tungsten alloys are used in applications requiring high mass, radiation shielding, and superior wear resistance. Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of these high-performance materials, offering top-quality products to meet the demanding needs of our global customers.

Product Parameters

| Property | Value |

|---|---|

| Tungsten Content (%) | 90-97 |

| Nickel Content (%) | 1-4 |

| Iron Content (%) | 1-4 |

| Density (g/cm³) | 17.0-18.5 |

| Hardness (HB) | 260-320 |

| Tensile Strength (MPa) | 700-1000 |

| Melting Point (°C) | 2,900-3,400 |

| Coefficient of Thermal Expansion (10^-6/°C) | 4.5-6.0 |

| Thermal Conductivity (W/m·K) | 120-150 |

| Electrical Conductivity (% IACS) | 15-30 |

| Diameter (mm) | Length (mm) | Tolerance (mm) |

|---|---|---|

| 5 | 1000 | ±0.05 |

| 15 | 2000 | ±0.15 |

| 25 | 3000 | ±0.25 |

| Mechanical Property | Value |

|---|---|

| Elastic Modulus (GPa) | 340 |

| Poisson's Ratio | 0.28 |

| Specific Heat (J/kg·K) | 140 |

|

|

Physical and Chemical Properties

Heavy metal tungsten alloys exhibit the following key properties:

High Density: Provides significant mass in compact forms, ideal for applications requiring substantial weight.

Superior Strength: High tensile strength and hardness ensure durability and wear resistance.

Thermal Stability:

Maintains structural integrity at high temperatures, suitable for extreme environments.Radiation Shielding: Excellent at absorbing and blocking radiation, making it ideal for medical and nuclear applications.

Corrosion Resistance: Resists oxidation and corrosion, enhancing longevity in harsh conditions.

|

|

Heavy Metal Tungsten Alloy Functions

High Density:

Heavy metal tungsten alloy enables the production of compact components with significant mass, essential for balancing and stabilization.

Superior Mechanical Strength:

Ensures durability and resistance to wear, extending the lifespan of components in demanding applications.

Thermal Stability:

Maintains structural integrity and performance at high temperatures, making it suitable for environments with high temperatures.

Radiation Shielding:

Protects against harmful radiation, crucial for medical, aerospace, and nuclear applications.

Corrosion Resistance:

Extends the life of components by resisting oxidation and corrosion, even in harsh conditions.

Product Applications

Aerospace and Defense:

Used in counterweights, ballast, and radiation shielding due to its high density and mechanical strength.

Medical Industry:

Employed in radiation shielding for imaging devices and protective gear, ensuring safety and precision.

Industrial Machinery:

Ideal for parts that require high wear obstruction and sturdiness, for example, tooling and shape.

Oil and Gas:

Utilized in drilling components and logging tools for its high density and corrosion resistance.

Automotive Industry:

Used in vibration dampening and counterweights to enhance vehicle performance and stability.

Manufacturing Process

Powder Blending:

High-purity tungsten and alloying elements are blended to achieve the desired composition.

Compaction:

The powder mixture is compacted into the desired shape using high pressure.

Sintering:

The compacted shape is sintered at high temperatures in a controlled atmosphere, bonding the particles into a solid mass.

Machining:

The sintered material is machined to precise dimensions and specifications, ensuring high-quality final products.

Inspection:

The finished products undergo rigorous quality control tests to ensure they meet the required standards.

This content looks too robotic

|

|

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is the most prominent producer of non-ferrous metals.

High-Density Tungsten Alloy primary focus is on the production of tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel alloys.

Our extensive product line includes more than one hundred distinct items, each created to meet the particular requirements of our global customers.

We've been zeroing in on trading great non-ferrous metal items beginning around 2010 and have major areas of strength for assembled with clients in Taiwan, Ukraine, South Korea, the US, Australia, Germany, Iran, and different countries.

We have laid out a standing as industry pioneers thanks to our obligation to quality and consumer loyalty.

Intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, vacuum annealing furnaces, rolling mills, wire drawing machines, plasma welding rooms, lathes, milling machines, sawing machines, drilling machines, shears, stamping equipment, cutting equipment, grinders, straightening machines, CNC machines, and a variety of other equipment are among the cutting-edge features of our cutting-edge production facilities.

This exceptional hardware permits us to reliably convey top notch items and administrations to our clients.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

Packaging Options:

Packaging made of wooden crates, cartons, and foam Packaging made of watertight and moisture-resistant packaging Custom packaging International standard packagingLogistics Options:

Ocean cargo

Airship cargo

Land transport

Multimodal transport

Expedited shipment administrations

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Broad Experience:

Over a decade of experience producing and supplying non-ferrous metals.

Products of Superior Quality:

Obligation to conveying items that fulfill the best guidelines.

New Technologies:

Modern manufacturing equipment and facilities.

Global Reach:

Established export network and long-term relationships with international clients.

Client Driven Approach:

Concentrate on satisfying customers and providing individualized solutions to meet specific requirements.

|

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services, providing customized solutions to meet the unique requirements of our clients.

Our team of experts works closely with customers to create products that are of high quality, meet their needs, and perform reliably.

|

|

Frequently Asked Questions (FAQ)

What is the typical composition of tungsten alloys made of heavy metals?

The majority of products contain nickel, iron, or copper in proportions of 90 to 97 percent.

What are the primary applications of heavy metal tungsten alloys?

Common applications include aerospace counterweights, radiation shielding, industrial machinery, oil and gas drilling components, and automotive vibration dampening.

How does heavy metal tungsten alloy perform in high-temperature environments?

These alloys exhibit excellent thermal stability, maintaining performance and structural integrity at high temperatures.

Can you provide custom sizes and shapes for heavy metal tungsten alloys?

Yes, we offer OEM/ODM services and can customize products to meet specific client requirements.

What are the shipping options for international orders?

We provide express delivery services, multimodal transportation, land transportation, sea freight, air freight, and other logistics options.

Contact us

We invite global buyers to partner with Shaanxi Peakrise Metal Co., Ltd. for high-quality heavy metal tungsten alloys and other non-ferrous metal products.

Our commitment to excellence and customer satisfaction ensures that you will receive the best products and services.

For more information or to place an order, please contact us at info@peakrisemetal.com.

We anticipate working with you and addressing your necessities with our top-level items and arrangements.