tungsten electrode for aluminium

Material: Pure Tungsten Or Doped Tungsten

Shape: Tungsten Electrode Rod

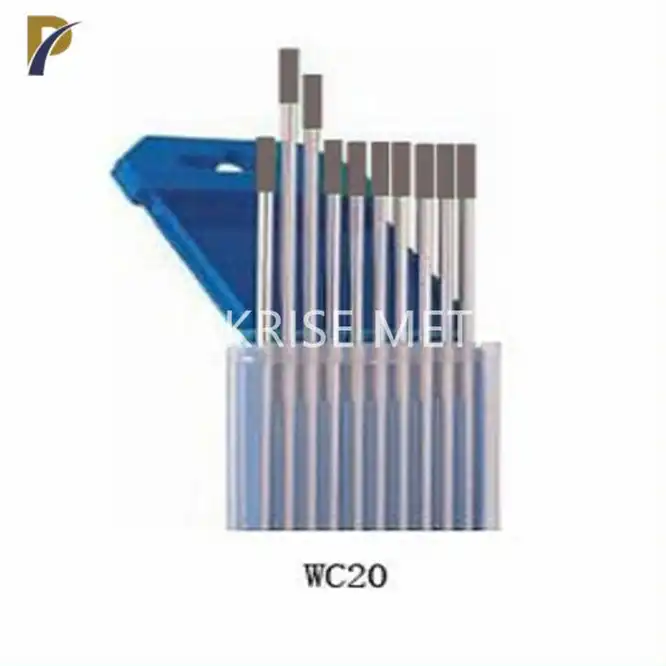

Grade: WT10,WT20,WC20,WL15,WZ3,WZ8,WY20 Etc.

Diameter: 1.0~4.8mm

Length: 150,175,178mm Or As Per Customer

Surface: Polished

Standard: ISO6848,AWS.A5.12 M

MOQ: 10pcs

Application: DC negative electrode welding of carbon steel, stainless steel, nickel and titanium, as well as some special AC welding

PRODUCT DESCRIPTION

Tungsten Electrode for Aluminium Product Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd.'s dedicated page for tungsten electrode for aluminium welding applications. As a prominent supplier in the non-ferrous metal industry, we pride ourselves on specializing in the provision of premium-grade tungsten products that cater impeccably to the rigorous standards and intricate requirements of contemporary welding processes. Our comprehensive range of tungsten electrodes, wires, and components are meticulously crafted to ensure maximum durability, precision, and efficiency, empowering professionals to achieve exceptional welding outcomes across diverse industrial applications.

Product Specifications

Below are the detailed specifications for our tungsten electrodes used in aluminum welding:

| Parameter | Value |

|---|---|

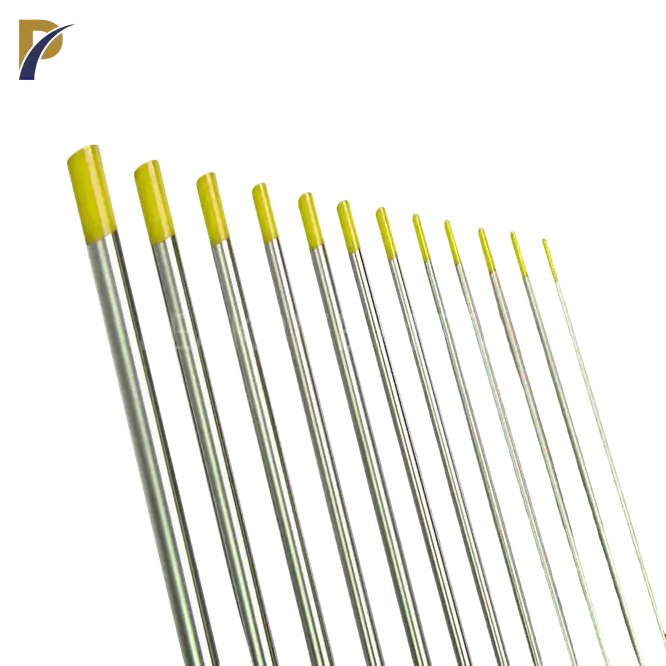

| Electrode Diameter | 1.6 mm, 2.4 mm, 3.2 mm |

| Electrode Length | 150 mm, 175 mm, 200 mm |

| Composition | 97% tungsten, 3% lanthanum oxide |

| Color | Sky Blue |

| Surface Finish | Ground |

| Arc Stability | Excellent |

|

|

Physical and Chemical Properties

Our Tungsten Electrode for Aluminium stands out for their unparalleled thermal conductivity and remarkable stability even under extreme temperatures, making them indispensable for achieving consistent arc performance and unparalleled weld quality. This exceptional property ensures that the electrodes maintain their structural integrity during the welding process, allowing for precise control over the welding parameters and resulting in clean, strong, and defect-free welds. Whether it's in the automotive, aerospace, or construction industries, our tungsten electrodes are relied upon for their reliability and superior performance.

|

|

Tungsten Electrode for aluminium Features

- Enhanced Arc Stability: Ensures smooth welding operations.

- Low Burn-Off Rate: Prolongs electrode life and reduces downtime.

- High Thermal Conductivity: Efficiently dissipates heat.

- Precision Ground Finish: Facilitates precise arc control.

Applications

- Tungsten electrode for aluminium: Ideal for TIG welding of aluminum alloys.

- Aerospace Industry: Used in aircraft manufacturing.

- Automotive Sector: Supports welding of aluminum components.

- Marine Applications: Critical for welding aluminum marine structures.

|

|

Production Process

Our Aluminium Welding Tungsten Electrode undergo advanced manufacturing processes including precision grinding and annealing to ensure superior quality and durability.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates state-of-the-art facilities equipped with intermediate frequency sintering furnaces, vacuum arc melting furnaces, and other advanced machinery to support large-scale production.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging:

- Wooden Cases

- Cartons

- Foam Cushioning

- Customized Packaging

Logistics:

- Sea Freight

- Air Freight

- Land Transport

- Multimodal Transport

- Express Services

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Extensive Industry Experience: Over a decade of expertise in non-ferrous metal production.

- Advanced Manufacturing Equipment: Utilization of cutting-edge technology for superior product quality.

- Global Reach: Established partnerships and satisfied customers across various countries.

- Customization Capabilities: Tailored solutions to meet specific client requirements.

|

|

OEM Services

We offer comprehensive OEM services to accommodate customized specifications, ensuring our products meet your exacting standards.

|

|

FAQs

-

What is the typical lifespan of your tungsten electrodes?

- Our tungsten electrode for aluminium are engineered to outlast standard electrodes by up to an impressive tenfold, showcasing remarkable durability and longevity. This extended lifespan translates into significant cost savings for our customers by reducing the frequency of electrode replacements and minimizing downtime during welding operations. Additionally, the longer-lasting nature of our electrodes ensures consistent and reliable welding performance throughout their service life, further enhancing the quality and efficiency of welding processes across various industries. With our electrodes, professionals can enjoy uninterrupted welding sessions and achieve superior results, time and time again.

-

Do you provide certifications for your products?

- Yes, we offer certificates of conformity and material test reports upon request.

-

Can your electrodes be used with AC and DC welding currents?

- Yes, they are compatible with both AC and DC welding.

-

What are the advantages of lanthanated tungsten electrodes?

- Lanthanated electrodes offer superior arc starting and stability compared to pure tungsten.

-

Do you ship internationally?

- Yes, we ship globally using reliable logistics partners.

Contact Us

Ready to elevate your welding capabilities with our tungsten electrode for aluminium? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com. Let's discuss how we can fulfill your welding needs efficiently and reliably.