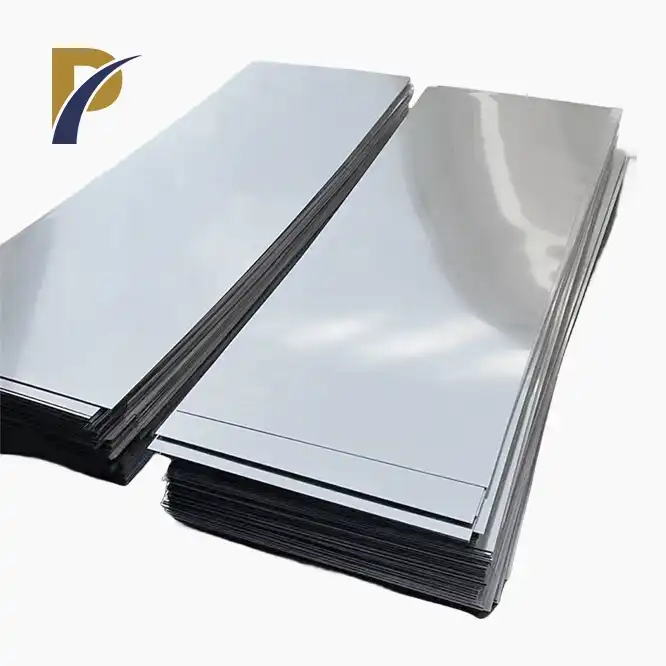

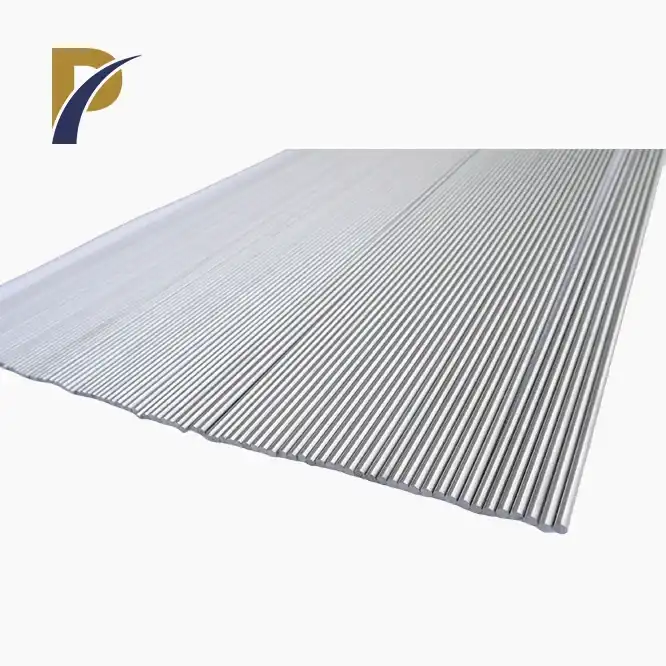

0.1mm molybdenum sheet /plate

Grade: Mo1,TZM,Mo-La,Mo-W Alloy

Purity: 99.95%, 99.97%

Density: 10.2g/cm3

Thickness: 0.2~20mm

Width: 10~700mm

Length: <2500mm

Surface: Bright,polished,Alkaline Washing

Standard: ASTM B386

Application: specialty steels. Molybdenum electrodes, vacuum furnace applications, nuclear power, missiles, and airplane parts.

PRODUCT DESCRIPTION

0.1mm Molybdenum Sheet /Plate Introduction

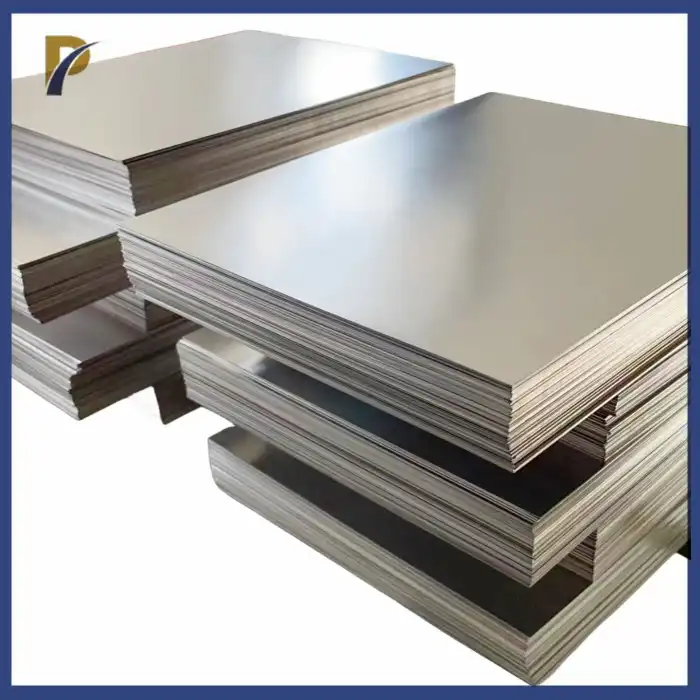

At Shaanxi Peakrise Metal Co., Ltd., we are pleased to present our high-precision 0.1mm molybdenum sheet /plate. Molybdenum is renowned in the industry for its exceptional properties, making it a preferred material in high-performance applications.

Molybdenum is an excellent choice for a variety of applications due to its high melting point, excellent thermal and electrical conductivity, and resistance to corrosion and wear. Shaanxi Peakrise Metal Co., Ltd. stands as a leading supplier of these specialized products, committed to delivering quality and precision to our global customers. Our 0.1mm Molybdenum Sheet is meticulously manufactured to cater to the needs of industries such as aerospace, electronics, and scientific research, where precision and durability are crucial.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Molybdenum |

| Purity | 99.95% |

| Thickness | 0.1 mm |

| Density | 10.28 g/cm³ |

| Melting Point | 2623°C |

| Thermal Conductivity | 138 W/m·K |

| Tensile Strength | 350 MPa |

| Hardness | 200 HV |

| Young's Modulus | 330 GPa |

| Plate Size | Customizable |

|

|

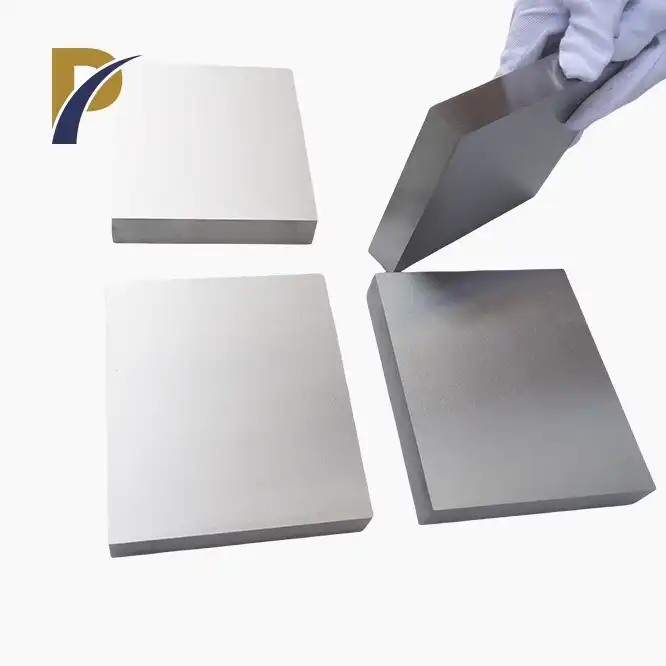

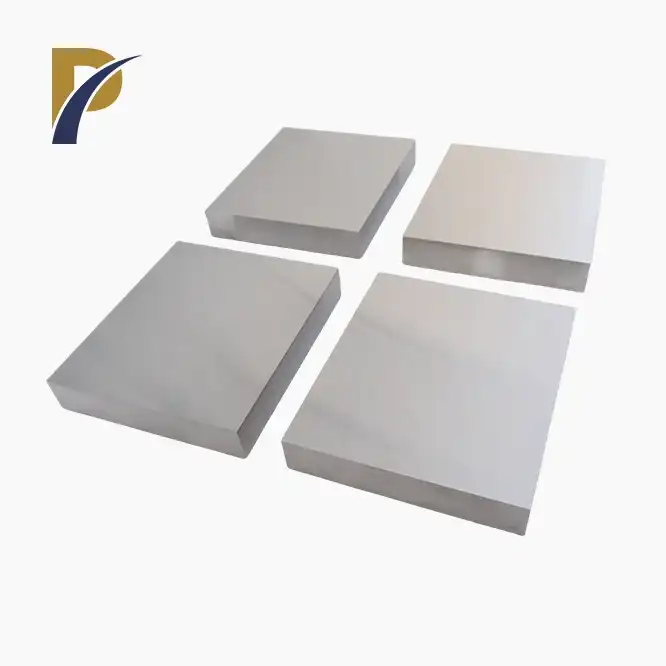

0.1mm Molybdenum Sheet /Plate Functions

High-Temperature Stability: With a melting point of 2623°C, our 0.1mm molybdenum sheet /plate remain stable and reliable even in extreme temperatures, making them ideal for high-temperature industrial processes.

Exceptional Thermal Conductivity: The high thermal conductivity of 138 W/m·K enables efficient heat transfer, essential for applications involving heat dissipation and thermal management.

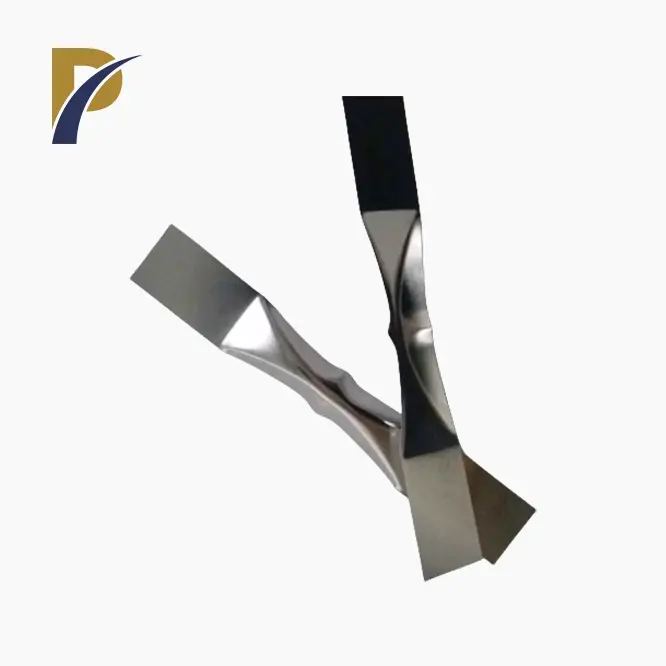

Mechanical Strength: Featuring a tensile strength of 350 MPa, these sheets/plates offer robust mechanical performance, suitable for high-stress environments.

Corrosion Resistance: Molybdenum’s resistance to corrosion ensures long-term durability and reliability in harsh environments, including chemical processing and high-moisture settings.

Product Applications

Aerospace Components: The high-temperature stability and strength of our Molybdenum Plate 0.1mm make them ideal for aerospace applications such as engine parts, heat shields, and thermal protection systems.

Electronics Manufacturing: In electronics, these sheets/plates are used for heat sinks, sputtering targets, and other components requiring high thermal conductivity and durability.

Industrial Furnaces: Our products are used in furnace linings and other high-temperature industrial processes where their thermal and mechanical properties enhance performance.

Scientific Research: Researchers utilize these sheets/plates in experimental setups and high-tech equipment where precise material properties are essential.

|

|

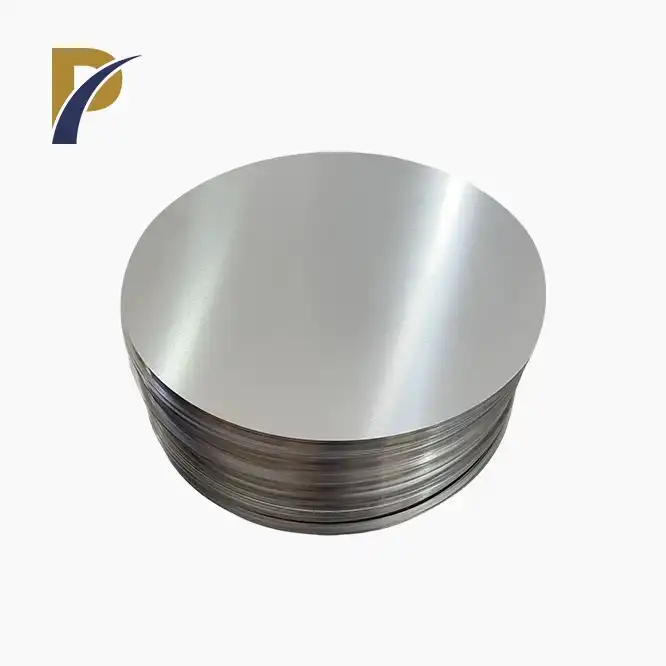

Production Process

Material Sourcing: We begin with high-purity molybdenum powders to ensure the highest quality for our sheets/plates.

Powder Metallurgy: The powders are blended, compacted, and sintered in a vacuum furnace to form a dense, high-quality material.

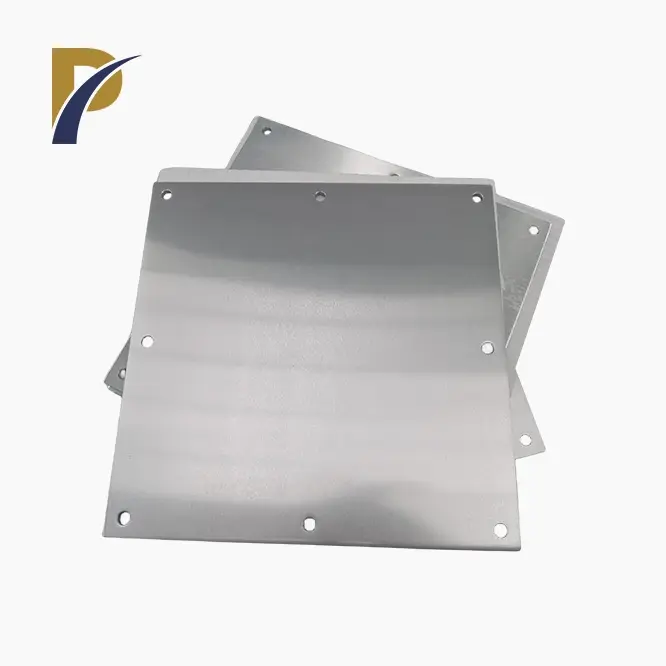

Sheet Formation: The sintered material is rolled or pressed to create sheets of 0.1mm thickness, tailored to customer specifications.

Precision Machining: The sheets are cut and finished to exact dimensions and surface requirements.

Quality Control: Each sheet undergoes rigorous testing and inspection to ensure it meets all quality and performance standards.

|

|

|

Company Overview

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer of non-ferrous metals and alloys, specializing in tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Since 2010, we have expanded our focus on international markets, providing high-quality products and solutions to global customers.

Our advanced production facilities feature equipment such as intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, and more. This technology allows us to produce precise and reliable products that meet the highest industry standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

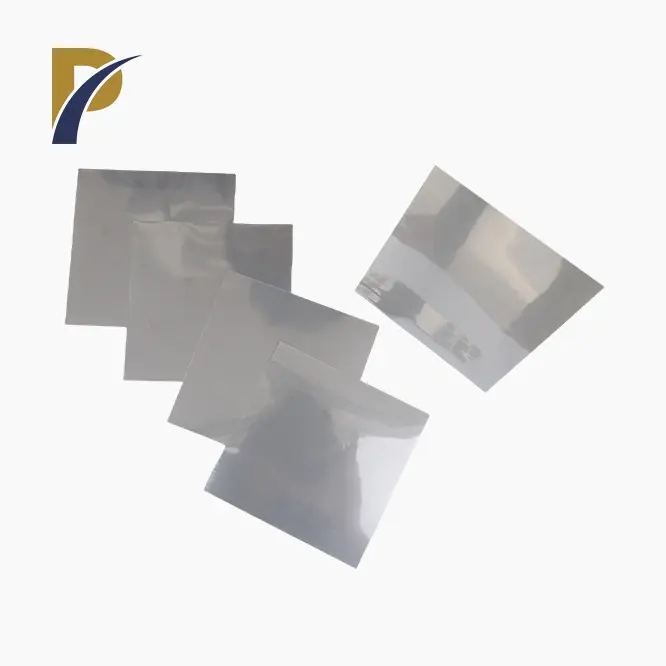

Packaging

Wooden Crates: Ideal for larger quantities and heavier sheets, ensuring secure and safe transportation.

Cardboard Boxes: Suitable for smaller orders, providing protection during transit.

Foam Padding: Cushions and protects sheets from damage during shipping.

Waterproof and Moisture-Proof Packaging: Protects sheets from environmental factors, ensuring they arrive in excellent condition.

Custom Packaging: Tailored solutions based on specific customer needs and requirements.

International Standards: All packaging complies with global shipping and handling regulations.

Logistics

Sea Freight: Cost-effective for large orders and international shipments.

Air Freight: Fast delivery for urgent and high-value shipments.

Land Transport: Efficient for regional and domestic distribution.

Multimodal Transport: Combines various transport methods for optimal logistics solutions.

Courier Services: Expedited shipping for smaller or urgent deliveries.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Extensive Experience: Over a decade of expertise in producing and supplying high-quality molybdenum sheets/plates.

Advanced Technology: Utilization of state-of-the-art equipment and processes to ensure precision and quality.

Global Reach: Established relationships with customers worldwide, known for reliability and service.

Rigorous Quality Control: Comprehensive testing and inspection to ensure products meet the highest standards.

Customer-Focused: Flexible solutions and dedicated support tailored to meet diverse customer needs.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers OEM and ODM services to provide customized 0.1mm molybdenum sheet /plate tailored to specific applications and requirements. Our team works closely with clients to deliver products that meet precise specifications and enhance performance.

|

|

FAQ

- What are the standard sizes of the products? Our standard thickness is 0.1mm, but we can customize sizes and dimensions according to customer specifications.

- What industries use them? These sheets/plates are used in aerospace, electronics manufacturing, industrial furnaces, and scientific research.

- How are the sheets/plates manufactured? The process includes material sourcing, powder metallurgy, sheet formation, precision machining, and quality control.

- Can you provide custom sizes and specifications? Yes, we offer OEM and ODM services to produce customized sheets/plates based on specific requirements.

- What quality control measures are in place? Each sheet/plate undergoes rigorous testing for density, hardness, thermal conductivity, and other key properties.

For high-quality 0.1mm molybdenum sheet /plate and expert service, reach out to Shaanxi Peakrise Metal Co., Ltd. We are dedicated to providing premium materials and tailored solutions to meet your needs. Contact us today at info@peakrisemetal.com to discuss your requirements and place your order.