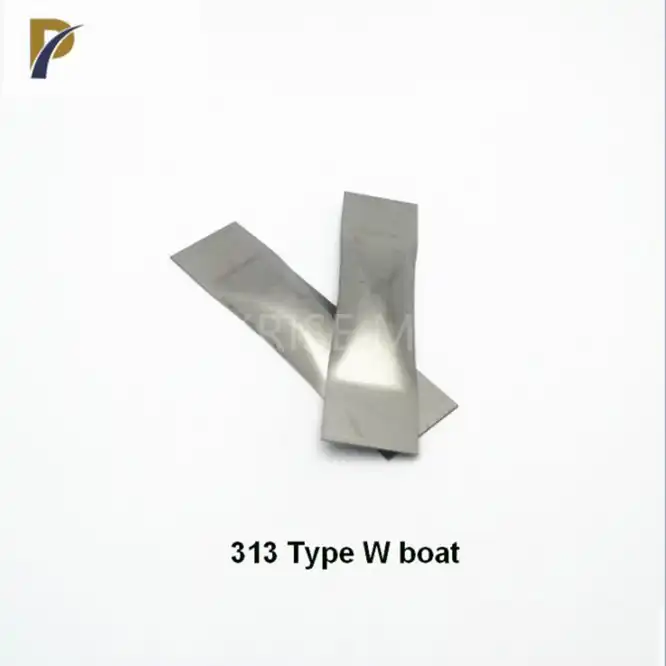

tungsten evaporation boat

Material: Pure Tungsten

Model: #207,#215,#308,#310,#315,#413,#525

Craft: Stamping

Applictaion: For Evaporation Coating

Purity : Min.99.95%

Density: 19.3g/cm3

Melting Point : 3407℃

PRODUCT DESCRIPTION

Tungsten Evaporation Boat Introduction

At Peakrise Metal, we specialize in manufacturing high-quality tungsten evaporation boat. These boats are designed to meet the stringent requirements of various industrial and scientific applications, ensuring reliable and efficient evaporation processes.

Product Specifications

| Parameter | Description |

|---|---|

| Material | Tungsten (W) |

| Purity | ≥ 99.95% |

| Density | 19.3 g/cm³ |

| Melting Point | 3,422°C |

| Boiling Point | 5,555°C |

| Surface Condition | Bright or Matte Finish |

| Dimensions | Customizable (Length × Width × Thickness) |

| Typical Dimensions | 100 mm × 10 mm × 0.2 mm (customizable) |

| Operating Temperature | 1,600°C to 2,400°C |

| Electrical Resistivity | 5.5 μΩ·cm |

| Thermal Conductivity | 173 W/m·K (at 20°C) |

| Coefficient of Thermal Expansion | 4.5 × 10⁻⁶ /K (20°C - 1,600°C) |

| Tensile Strength | 500 - 700 MPa |

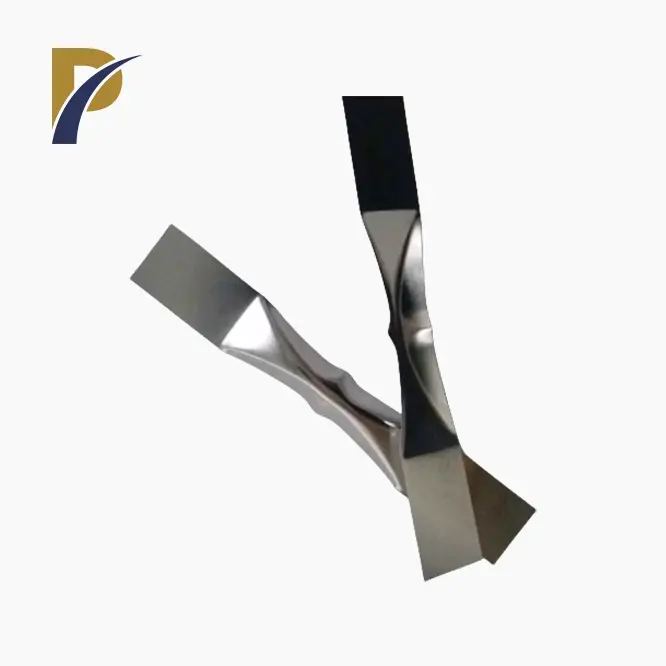

| Bend Test | 180° without fracture |

| Corrosion Resistance | High resistance to most acids and alkalis |

| Packaging | Vacuum-sealed or as per customer request |

| Applications | Thin-film coating, vacuum evaporation, etc. |

|

|

Physical and Chemical Properties

Our Welding Tungsten Boat exhibits exceptional thermal stability, high density, and excellent resistance to chemical corrosion. They are meticulously engineered to ensure uniform thickness distribution and prolonged service life in vacuum environments.

|

|

Product Features

- High Purity Material: Ensures minimal contamination during evaporation processes.

- Customizable Dimensions: Tailored to meet specific application requirements.

- Uniform Heat Distribution: Facilitates precise deposition across substrates.

- Durable Construction: Withstands high temperatures and thermal cycling.

- Consistent Performance: Reliable for both R&D and large-scale production.

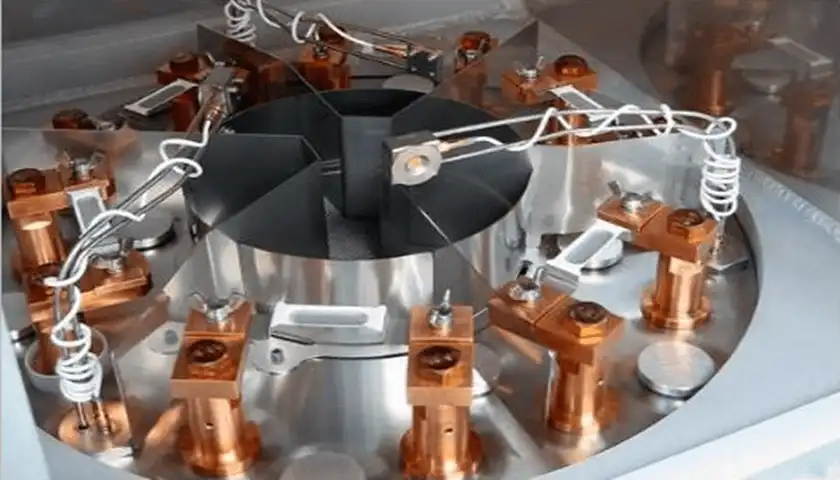

Applications

- Thin Film Deposition: Essential for semiconductor manufacturing.

- Optical Coating: Ensures high optical transmission properties.

- Research & Development: Supports advancements in materials science.

- Solar Cells: Contributes to efficient energy conversion technologies.

|

|

Production Process

At Shaanxi Peakrise Metal Co., Ltd., each tungsten evaporation boat undergoes advanced manufacturing processes including vacuum sintering and precision machining. Our state-of-the-art facilities guarantee superior quality and adherence to international standards.

|

|

|

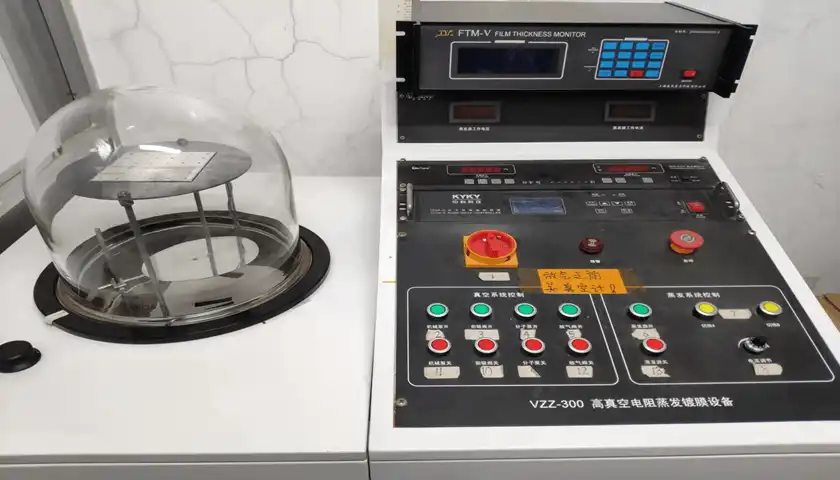

Our Factory

Equipped with cutting-edge technology such as vacuum arc melting furnaces and CNC machining centers, our facility enables us to maintain rigorous quality control from raw materials to finished products.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

- Wooden Crates: Suitable for large-scale shipments.

- Cardboard Boxes: Ideal for smaller orders.

- Foam Cushioning: Ensures High-Strength Tungsten Welding Boat integrity during transit.

- Custom Packaging: Tailored to specific customer needs.

- International Standards: Meets global shipping regulations.

Logistics

- Sea Freight: Cost-effective for bulk orders.

- Air Freight: Expedited delivery for urgent requirements.

- Land Transportation: Efficient for regional distribution.

- Multimodal Transport: Integrated solutions for complex logistics needs.

- Courier Services: Swift and reliable door-to-door delivery.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Shaanxi Peakrise Metal Co., Ltd. distinguishes itself with:

- Extensive Industry Experience: Over a decade of excellence in non-ferrous metal production.

- Global Reach: Trusted by clients worldwide, including Taiwan, Ukraine, and the USA.

- Customization Expertise: Tailoring products to meet unique specifications.

- Commitment to Quality: Rigorous testing and quality assurance processes.

|

OEM Services

We offer comprehensive OEM services to meet specific client requirements, ensuring flexibility and personalized solutions for every project.

|

|

FAQ

- What is the typical lead time for orders?

- Lead times vary based on order volume and customization. Contact us for specific timelines.

- Can you accommodate rush orders?

- Yes, we offer expedited manufacturing and shipping options for urgent orders.

- Are your products compliant with industry standards?

- Yes, all products adhere to stringent quality and safety regulations.

- Do you provide technical support for product installation?

- Our team offers expert guidance and support throughout the installation process.

- What payment methods do you accept?

- We accept wire transfers, credit cards, and other secure payment methods.

Contact Us

Explore how Shaanxi Peakrise Metal Co., Ltd. can enhance your thin film deposition processes with our superior tungsten evaporation boats. Reach out to us at info@peakrisemetal.com to discuss your requirements and begin a partnership built on reliability and excellence.

YOU MAY LIKE

-

VIEW MOREtungsten sintering boat

VIEW MOREtungsten sintering boat -

VIEW MOREwelding tungsten boat

VIEW MOREwelding tungsten boat -

VIEW MOREmolybdenum threaded rod

VIEW MOREmolybdenum threaded rod -

VIEW MOREpure tungsten electrode

VIEW MOREpure tungsten electrode -

VIEW MOREmolybdenum sintering boats

VIEW MOREmolybdenum sintering boats -

VIEW MOREmolybdenum lanthanum furnace boats

VIEW MOREmolybdenum lanthanum furnace boats -

VIEW MOREheavy metal tungsten alloy

VIEW MOREheavy metal tungsten alloy -

VIEW MOREmolybdenum high temperature alloy tzm rod

VIEW MOREmolybdenum high temperature alloy tzm rod