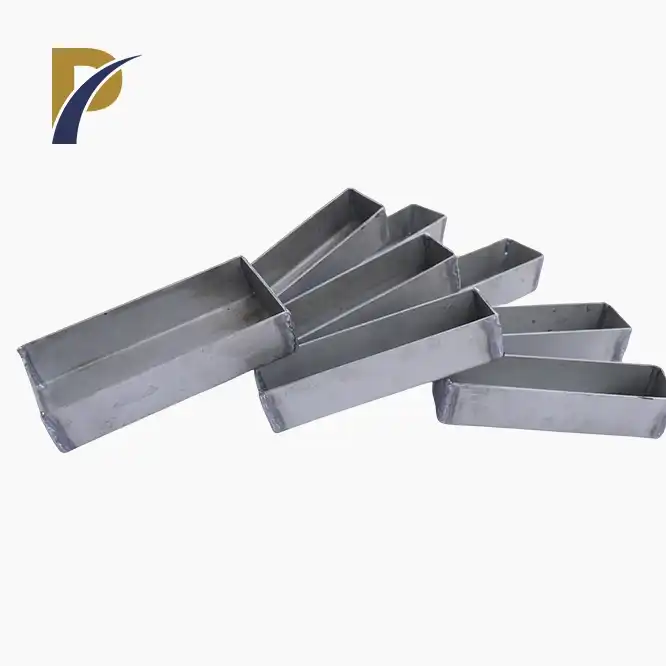

welding tungsten boat

Purity: 99.95%

Density: 19.3 G/cm3

Thermal Expansion Coefficient: 4.5×10^-6/℃

Surface:Alkaline Washing,Polished

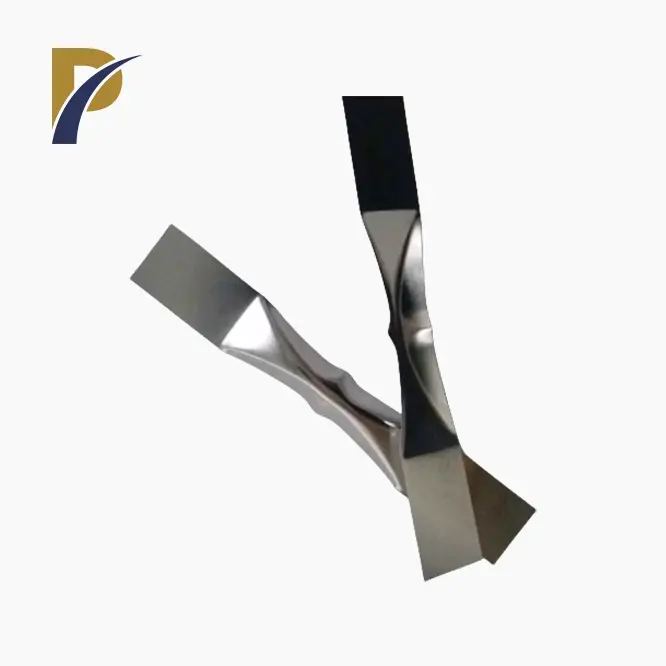

Process Method:Welding,riveting,folding,stamping

Use Temperature: 2200℃~2800℃

PRODUCT DESCRIPTION

Welding Tungsten Boat Introduction

Welcome to the official product page of welding tungsten boats by Shaanxi Peakrise Metal Co., Ltd. Here, we are committed to excellence in providing top-tier tungsten products specifically designed for the rigors of industrial applications. As a prominent leader in our field, we pride ourselves on offering an extensive array of tungsten materials that not only meet but exceed the stringent requirements of contemporary manufacturing processes.

Product Parameters

| Parameter | Description |

|---|---|

| Material | Tungsten (W) |

| Purity | ≥ 99.95% |

| Density | 19.3 g/cm³ |

| Melting Point | 3,422°C |

| Dimensions | Customizable (Length × Width × Thickness) |

| Typical Dimensions | 100 mm × 20 mm × 0.5 mm (customizable) |

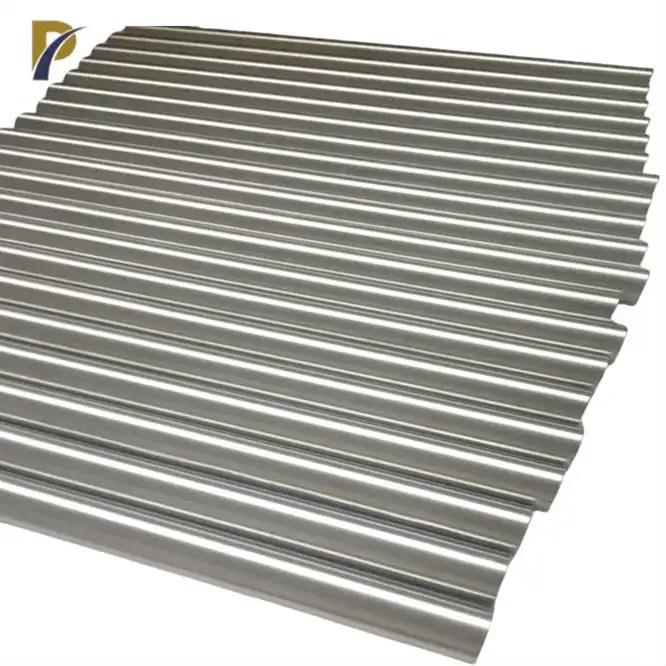

| Surface Condition | Machined, Ground, or Polished |

| Operating Temperature | Up to 2,800°C |

| Thermal Conductivity | 173 W/m·K (at 20°C) |

| Electrical Resistivity | 5.5 μΩ·cm |

| Coefficient of Thermal Expansion | 4.5 × 10⁻⁶ /K (20°C - 1,600°C) |

| Weldability | Excellent weldability and thermal stability |

| Mechanical Properties | High strength and ductility at elevated temperatures |

| Tensile Strength | 500 - 700 MPa |

| Manufacturing Process | Fabrication and welding |

| Corrosion Resistance | High resistance to most acids and alkalis |

| Packaging | Vacuum-sealed or as per customer request |

| Applications | Vacuum evaporation, high-temperature welding, etc. |

|

|

Physical and Chemical Properties

Welding tungsten boats from Shaanxi Peakrise Metal Co., Ltd. exhibit exceptional durability and high melting points, making them ideal for thermal evaporation applications. Our products are engineered to withstand extreme temperatures and provide reliable performance in vacuum environments.

|

|

Welding Tungsten Boat Functions

- High Temperature Resistance: With a melting point of 3410°C, our tungsten boats ensure stability under high heat conditions.

- Uniform Thickness: Precision machined for consistent thickness, crucial for even material deposition.

- Chemical Inertness: Resistant to chemical reactions, ensuring purity of deposited materials.

- Customizable Dimensions: Tailored to meet specific application requirements, ensuring optimal performance.

- Longevity: Durable construction extends service life, minimizing downtime and maintenance costs.

Product Applications

Our Polished Tantalum Rod boats are widely used in:

- Semiconductor manufacturing

- Thin film deposition

- Optical coating processes

- Solar cell production

- Research and development

|

|

The trend towards miniaturization and efficiency in manufacturing processes further enhances the demand for our high-quality tungsten products.

Manufacturing Process

At Shaanxi Peakrise Metal Co., Ltd., we utilize advanced equipment such as vacuum arc melting furnaces and precision machining tools to ensure the highest quality standards in production. Each High-Strength welding tungsten boat undergoes rigorous testing to meet customer specifications and industry regulations.

|

|

|

Why Choose Us?

Shaanxi Peakrise Metal Co., Ltd. stands out with:

- Extensive Industry Experience: Over a decade of expertise in non-ferrous metal production.

- Advanced Manufacturing Facilities: Equipped with state-of-the-art technology for precise fabrication.

- Global Reach: Trusted by clients worldwide for our commitment to quality and reliability.

- Customization Capabilities: Offering OEM services to tailor products to unique requirements.

|

|

OEM Services

We offer comprehensive OEM/ODM services, collaborating closely with clients to develop customized solutions that meet specific application needs.

|

|

FAQs

- What is the typical lead time for orders?

- Lead times vary based on order size and customization requirements. Contact us for specific timelines.

- Can you provide samples for testing purposes?

- Yes, we offer samples for evaluation upon request. Please inquire for more details.

- Are your products compliant with international standards?

- Our welding tungsten boat meet stringent quality standards and are compliant with relevant international regulations.

- Do you offer packaging customization?

- Yes, we provide customizable packaging solutions to ensure safe transit and storage of our products.

- What are your shipping options?

- We offer flexible shipping options including sea freight, air freight, and express services to meet diverse customer needs.

Packaging

Our products are meticulously packaged to ensure:

- Protection against moisture and environmental damage.

- Compliance with international shipping standards.

- Customized packaging solutions available upon request.

Logistics

We offer a variety of logistics solutions:

- Sea Freight: Cost-effective for bulk shipments.

- Air Freight: Quick delivery for urgent orders.

- Land Transportation: Reliable domestic and regional distribution.

- Multi-modal Transport: Integrated solutions for complex shipping needs.

- Express Services: Fast and secure delivery options.

|

|

|

|

|

|

|

|

|

|

Contact Us

Ready to elevate your production with our premium welding tungsten boats Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com to discuss your requirements and explore partnership opportunities.