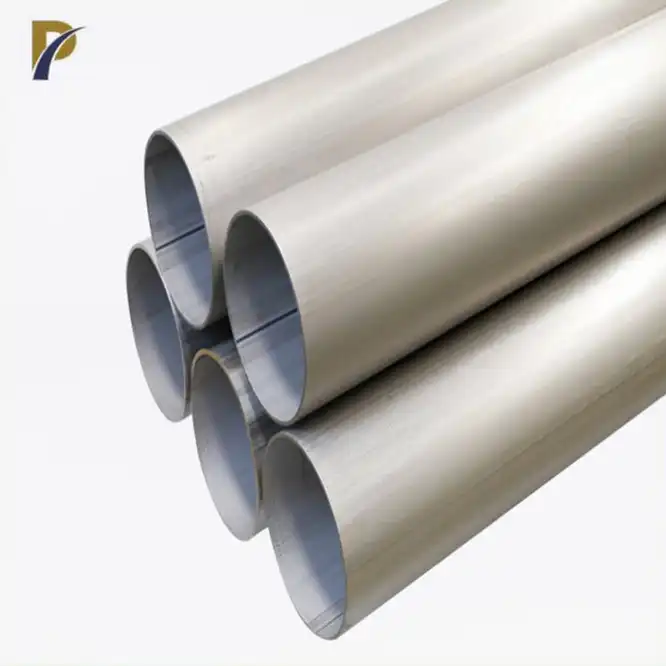

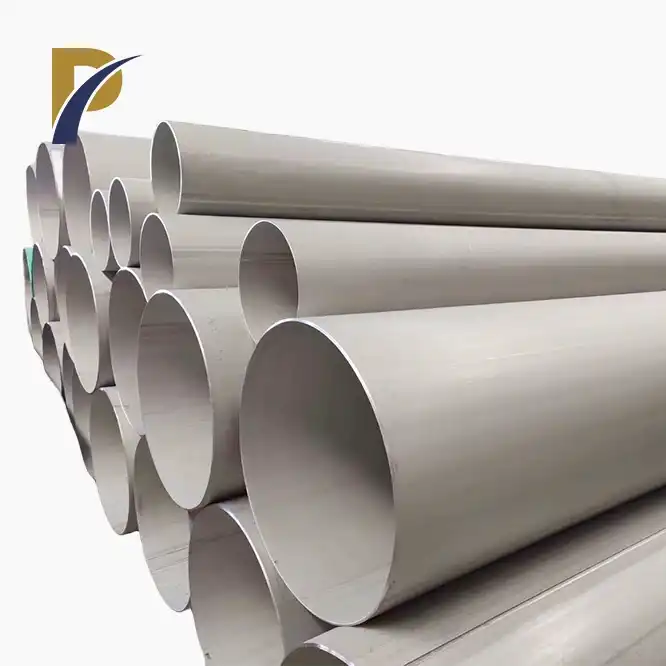

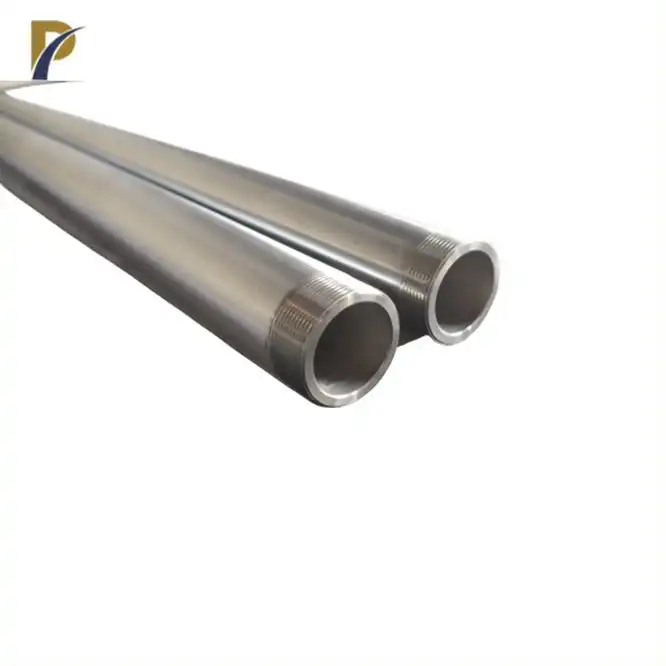

titanium pipes & tubes

Material: Titanium Alloy

Grade: Gr5 Gr7 Gr9 TC10 TC4 TC11

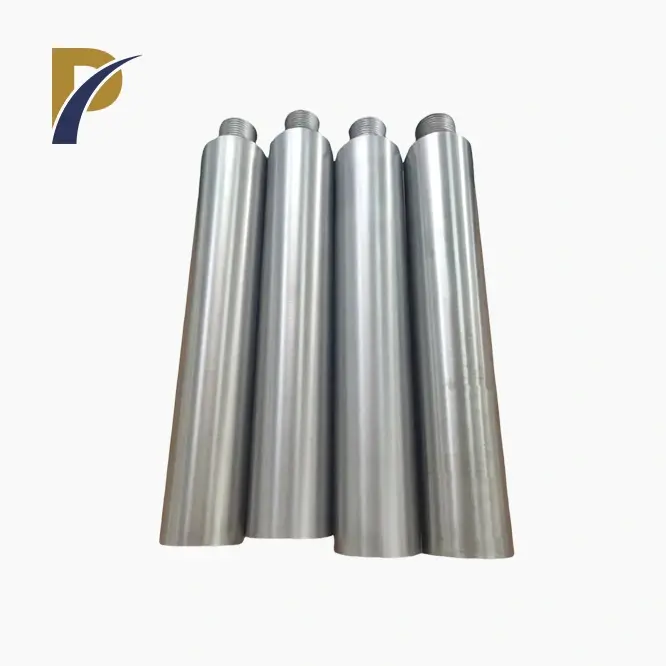

Shape: Seamless Tube

Outdiameter: 3.3-114.3mm

Wall Thickness: 0.1-10mm

Surface: Pickling, Sandblasting, Bright

Standard: ASTM B337,ASTM B338,ASTM B861

Application: Heat exchangers and condensers.Various corrosive fluid delivery pipeline systems.Titanium bicycle tubes, automobile exhaust pipes etc.

Origin: China Titanium Valley

PRODUCT DESCRIPTION

Titanium Pipes & Tubes Introduction

At Shaanxi Peakrise Metal Co., Ltd., we specialize in providing high-quality titanium pipes & tubes designed to meet the diverse needs of various industries. Our High-Purity Titanium TIG Welding Rod and tube are manufactured to the highest standards, ensuring durability, performance, and precision for applications that demand reliability and resilience.

Product Specifications

General Specifications

| Property | Specification |

|---|---|

| Material | Titanium (Grade 1, 2, 5, 7, 9, 12, 23) |

| Outer Diameter (OD) | 6 mm to 200 mm |

| Wall Thickness | 0.5 mm to 10 mm |

| Length | Customizable up to 6000 mm |

| Surface Finish | Annealed, Polished, Matte |

| Standards | ASTM B338, ASTM B861, ASTM B862 |

Mechanical Properties

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ |

| Tensile Strength | 240 MPa to 550 MPa (varies by grade) |

| Yield Strength | 170 MPa to 480 MPa (varies by grade) |

| Elongation | 15% to 20% |

| Hardness | Rockwell B80 - B90 |

Chemical Composition

| Element | Weight Percentage |

|---|---|

| Titanium (Ti) | 99.5% min |

| Iron (Fe) | 0.2% max |

| Oxygen (O) | 0.25% max (Grade 1), 0.2% max (Grade 2) |

| Carbon (C) | 0.1% max |

| Nitrogen (N) | 0.05% max |

|

|

Physical and Chemical Properties

Our Titanium TIG Welding Rod and tube offer several key properties:

Corrosion Resistance: Exceptional resistance to oxidation and corrosion in harsh environments, including acidic and alkaline solutions.

High Strength-to-Weight Ratio: Lightweight yet strong, making it ideal for applications where weight reduction is crucial.

Biocompatibility: Safe for medical implants and devices, with excellent biocompatibility.

Temperature Stability: Maintains its properties even at high temperatures, suitable for extreme conditions.

|

|

Titanium Pipes & Tubes Functions

Aerospace: Lightweight and high-strength properties make these pipes ideal for aerospace applications, including structural components and fuel lines.

Medical: Biocompatibility allows for use in medical implants and surgical instruments.

Chemical Processing: Excellent corrosion resistance makes it suitable for handling chemicals and acids.

Automotive: titanium pipes & tubes are used in high-performance and racing applications for reduced weight and improved durability.

Product Applications

Aerospace Industry: titanium pipes & tubes are used in aircraft structures, engine components, and hydraulic systems.

Medical Field: Employed in orthopedic implants, dental implants, and surgical tools due to their biocompatibility and strength.

Chemical Processing Plants: Ideal for pipes and tubes in environments where corrosion and high temperatures are a concern.

Automotive Sector: Utilized in high-performance vehicles for exhaust systems and structural components to enhance performance and reduce weight.

|

|

Production Process and Craftsmanship

Our titanium pipes & tubes are produced using state-of-the-art technology:

Material Selection: High-purity titanium billets are selected based on stringent quality criteria.

Extrusion and Machining: The billets are extruded and machined to precise dimensions and tolerances.

Heat Treatment: The pipes undergo heat treatment to enhance mechanical properties and relieve stress.

Surface Finishing: Various surface finishes, including annealed, polished, and matte, are applied based on customer requirements.

Quality Control: Each product undergoes rigorous testing to ensure compliance with industry standards and specifications.

|

|

|

About Shaanxi Peakrise Metal Co., Ltd.

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer of non-ferrous metals, specializing in tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Established with a focus on providing high-quality metal products, we have expanded our operations to include advanced manufacturing, material research, product testing, and global distribution.

Our factory is equipped with a range of modern production equipment, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma welding rooms, and CNC machines. This extensive equipment allows us to meet diverse customer needs with precision and efficiency.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

Wooden Crates: For secure and safe transportation, our products are packed in sturdy wooden crates.

Carton Boxes: Lightweight and cost-effective packaging for standard orders.

Foam Fillers: Used to protect products from damage during transit.

Waterproof and Moisture-Proof Packaging: Ensures products are protected from environmental conditions.

Custom Packaging: Tailored packaging solutions to meet specific customer requirements.

International Standards: All packaging complies with international shipping standards.

Logistics

Sea Freight: Reliable and cost-effective shipping for bulk orders.

Air Freight: Fast delivery for urgent or high-value shipments.

Land Transport: Efficient for domestic deliveries and regional distribution.

Multimodal Shipping: Combines different modes of transport for optimized logistics.

Courier Services: Quick and convenient for smaller orders and urgent deliveries.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Expertise: Extensive experience in manufacturing high-quality non-ferrous metals.

Advanced Technology: Use of modern production equipment and techniques.

Quality Assurance: Rigorous testing and quality control processes.

Global Reach: Established relationships with customers worldwide.

Customer-Centric Approach: Focus on meeting customer needs with tailored solutions.

|

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer customized manufacturing services to meet your specific requirements. Whether you need special dimensions, materials, or surface treatments, our team is ready to provide tailored solutions to fit your needs.

|

|

Frequently Asked Questions

1. What grades of titanium are available for pipes and tubes?

We offer High-Purity Titanium TIG Welding Rod and tube in various grades including Grade 1, 2, 5, 7, 9, 12, and 23.

2. Can you provide custom sizes and lengths?

Yes, we can customize dimensions and lengths based on your specifications.

3. What is the standard lead time for orders?

The standard lead time is typically 4-6 weeks, depending on the order size and customization.

4. Are your products certified?

Yes, our products comply with international standards such as ASTM B338 and ASTM B861.

5. How do you ensure the quality of your products?

We perform rigorous testing and quality control at every stage of the production process.

Contact Us

To learn more about our titanium pipes & tubes or to request a quote, please contact us at:

Email: info@peakrisemetal.com