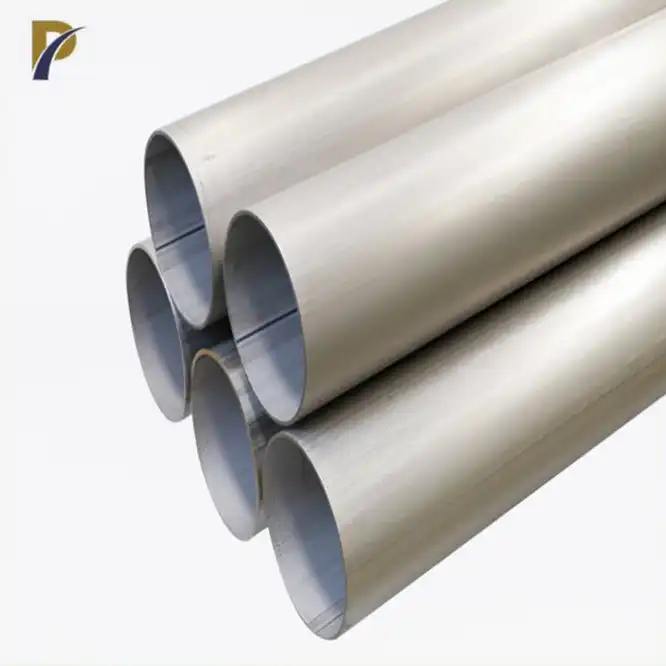

welding titanium tube

Material: Pure Titanium & Titanium alloy

Grade: Gr1 Gr2 TC10

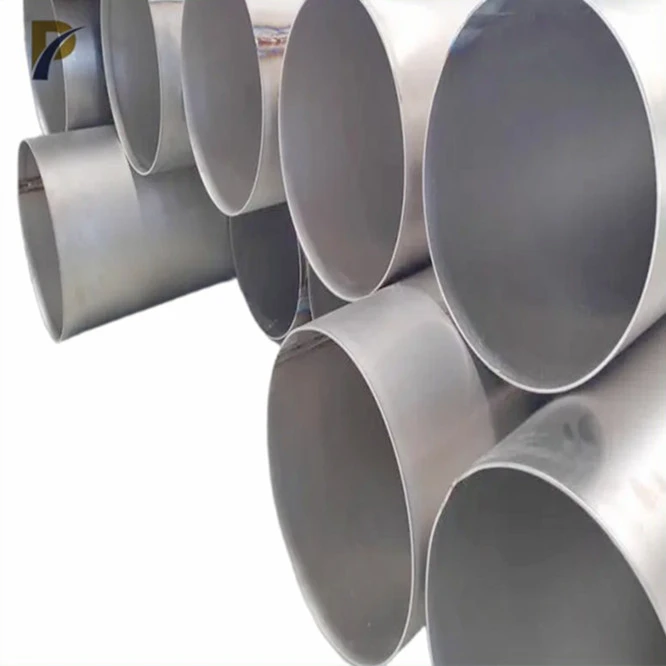

Shape: Large Diameter Welded Pipe

Diameter: Max. 1000mm

Wall Thickness: 0.5-8.0mm

Surface: Pickling, Sandblasting, Bright

Standard:ASTM B862,ASTM B338,JIS H4631,JIS H4635

Origin: China Titanium Valley

Inspection: Eddy current flaw detection,Hydrostatictes

PRODUCT DESCRIPTION

Welding Titanium Tube Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of welding titanium tube. With a wealth of experience in the production of non-ferrous metals, including titanium, we pride ourselves on delivering high-quality products tailored to meet global standards.

Product Specifications

Here are the detailed specifications of our welding titanium tube:

| Parameter | Value |

|---|---|

| Material | Titanium |

| Diameter Range | 6mm - 50mm |

| Wall Thickness | 0.5mm - 5mm |

| Length | Customizable |

| Tolerance | ±0.1mm |

| Surface Finish | Polished |

| Welding Technique | TIG Welding |

| Certification | ISO 9001:2015 |

|

|

Physical and Chemical Properties

Our Titanium Rod exhibits excellent corrosion resistance, high strength-to-weight ratio, and superb weldability. They maintain integrity under extreme temperatures and harsh environments.

|

|

Welding Titanium Tube Features

Titanium Rod requires specific strategies and contemplations because of titanium's exceptional properties. Here are the key item highlights and contemplations for the it:

- High Solidarity to-Weight Proportion: It offers uncommon strength tantamount to steel yet with roughly 45% less weight. This makes them ideal for applications where weight decrease is basic without compromising primary respectability.

- Erosion Opposition: Titanium displays eminent protection from consumption, remembering for seawater and chloride conditions. This property guarantees life span and dependability in unforgiving circumstances, making titanium tubes appropriate for marine, compound, and aviation applications.

- Biocompatibility: Titanium is biocompatible and non-harmful, making Pure Titanium Rod reasonable for clinical inserts and careful instruments. They are generally utilized in muscular inserts, dental inserts, and prosthetics because of their similarity with the human body.

- High Temperature Obstruction: Titanium can endure high temperatures up to 600°C (1100°F) without critical misshapening or decay. This property is worthwhile in aviation applications and modern cycles including raised temperatures.

- Formability and Manufacture: Regardless of its solidarity, titanium is malleable and can be framed into different shapes, including tubes, through processes like consistent welding. This adaptability in creation considers redid plans and exact assembling to meet explicit application prerequisites.

- Accuracy Welding Methods: It requires particular strategies to forestall pollution and guarantee solid, sturdy joints. Cycles, for example, gas tungsten curve welding (GTAW or TIG) are regularly used to accomplish top notch welds with insignificant intensity impacted zones.

- Quality Confirmation and Testing: Producers stick to rigid quality principles and direct non-disastrous testing (NDT) to guarantee weld uprightness and by and large tube quality. This incorporates ultrasonic testing, radiographic assessment, and color penetrant testing to recognize any deformities or blemishes.

- Natural Maintainability: Titanium is recyclable and has a low ecological effect contrasted with different metals. Its long life expectancy and capacity to be reused add to economical assembling rehearses.

- Cost Contemplations: While titanium is more costly than certain metals, its unrivaled properties and life span frequently legitimize the underlying speculation, particularly in applications where its extraordinary attributes are fundamental.

Welding Titanium Tube Applications

The versatility of our Pure Titanium Rod extends to various industries:

- Aerospace: Structural components and fuel system conduits.

- Medical: Surgical implants and instruments.

- Marine: Heat exchangers and offshore piping.

- Chemical Processing: Reactors and pressure vessels.

|

|

Production Process

At Shaanxi Peakrise Metal Co., Ltd., we employ advanced manufacturing processes:

- Material Preparation

- Forming and Shaping

- Precision Welding

- Quality Inspection

|

|

|

Our Factory

Equipped with state-of-the-art facilities:

- Intermediate Frequency Sintering Furnace

- Vacuum Arc Melting Furnace

- Laser Cutting and CNC Machining Centers

- Comprehensive Testing Equipment

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

To ensure product safety during transit:

- Wooden Crates

- Cardboard Boxes

- Foam Cushioning

- Waterproof Sealing

- Customized Packaging

Logistics

We offer flexible shipping options:

- Sea Freight

- Air Freight

- Land Transportation

- Multi-modal Transport

- Expedited Delivery Services

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Shaanxi Peakrise Metal Co., Ltd. stands out due to:

- Extensive Industry Experience and Expertise

- Commitment to Quality and Compliance

- Global Reach and Reliable Supply Chain

- Customization Capabilities

|

OEM Services

We specialize in custom fabrication to meet unique specifications and designs.

|

|

Frequently Asked Questions

-

Can you customize tube dimensions beyond the listed range?

- Yes, we offer tailored solutions based on project requirements.

-

What certifications do your products hold?

- Our products are certified to ISO 9001:2015 standards.

-

How do you ensure product quality?

- We conduct rigorous quality checks at every stage of production.

-

What is the typical lead time for orders?

- Lead times vary based on order size and customization needs.

-

Do you provide material test reports?

- Yes, we provide comprehensive material test reports upon request.

Contact Us

Contact us today at info@peakrisemetal.com to discuss how Shaanxi Peakrise Metal Co., Ltd. can meet your welding titanium tube requirements. Partner with us for reliable quality and service excellence.