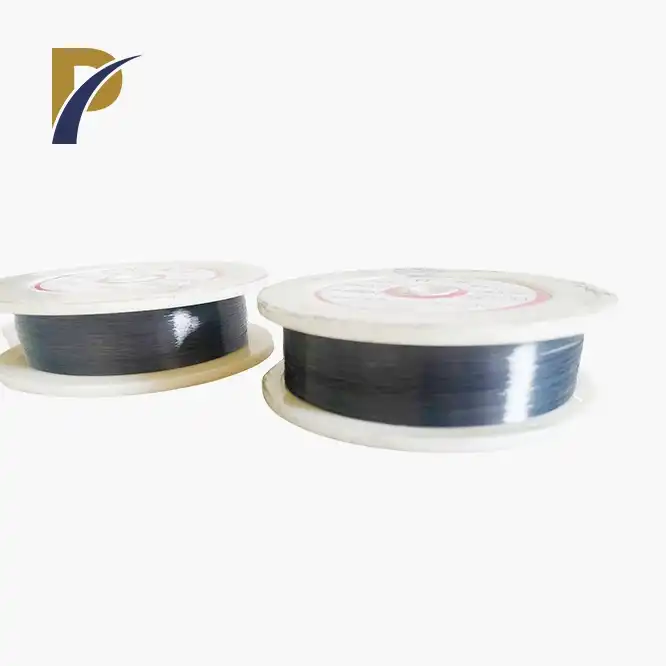

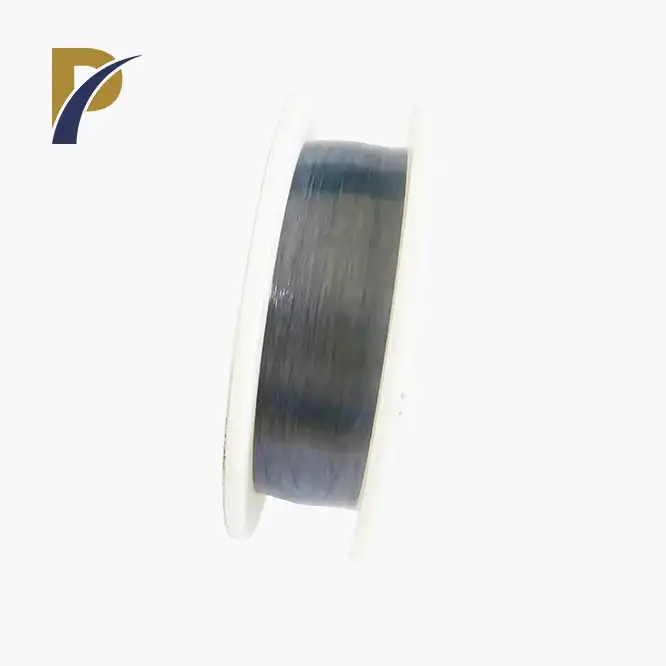

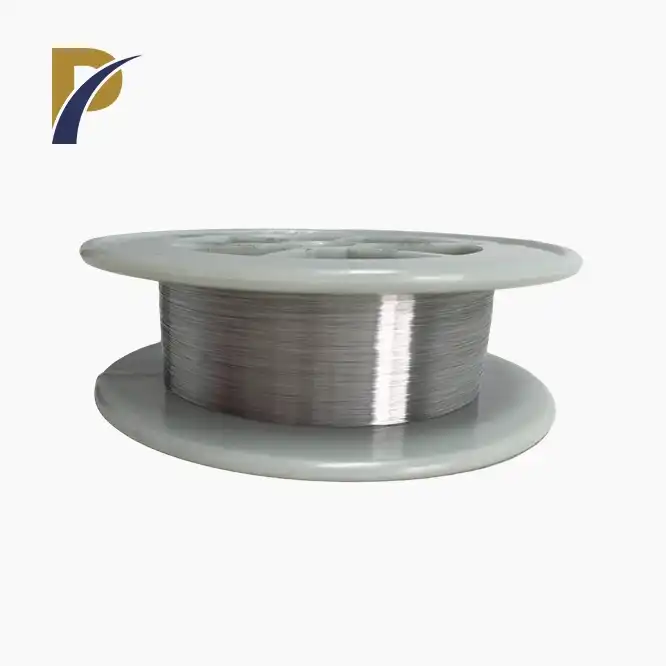

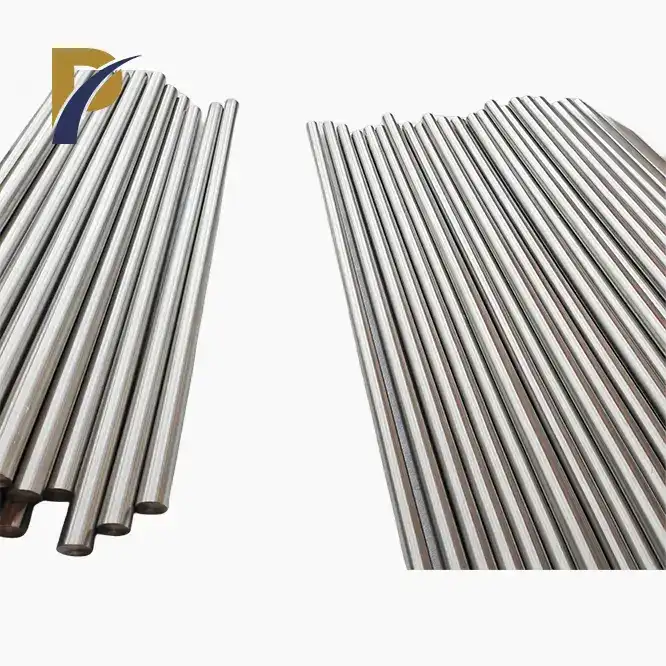

tungsten heating wire

Purity: >99.95%

Density: 19.3g/cm3

Shape: Door Type, Tapered, Or Custom

Wire Gauge: 0.6-1.0mm

Application: Vacuum Coating,heating Element

Surface: Bright

MOQ: 3kgs

PRODUCT DESCRIPTION

Tungsten Heating Wire Overview

Tungsten heating wire, renowned for its exceptional durability and efficiency, has become the preferred choice for various industrial and commercial heating applications. Shaanxi Peakrise Metal Co., Ltd., a leading manufacturer and supplier, consistently delivers high-quality products that meets the stringent standards of the global market. Their unwavering commitment to precision engineering and customer satisfaction sets them apart in the industry, ensuring that their products are synonymous with reliability and performance.

Product Parameters

| Parameter | Specification |

|---|---|

| Material | Pure Tungsten (W) or Tungsten Alloy |

| Diameter Range | 0.01 mm to 3.00 mm |

| Operating Temperature | Up to 2800°C in vacuum or inert atmospheres |

| Tensile Strength | Varies with diameter; generally between 2500 to 4000 MPa |

| Density | 19.25 g/cm³ |

| Melting Point | 3422°C |

| Electrical Resistivity | 5.5 µΩ·cm at 20°C |

| Surface Finish | Cleaned, oxidized, or as drawn |

| Length | Custom lengths, typically in spools or cut lengths |

| Tolerance | +/- 0.002 mm (may vary based on diameter) |

| Applications | High-temperature furnaces, heating elements, and evaporation sources |

Physical and Chemical Properties

Tungsten High-Purity Tungsten Target X-Ray Tube, known for its remarkable endurance and consistent performance, excels in environments where high temperatures are a constant challenge. Its inherent resistance to oxidation and corrosion not only protects it from wear and tear but also guarantees a significantly extended service life. This resilience is particularly beneficial in industries such as aerospace, automotive, and electronics, where reliability and longevity are paramount. The wire's ability to maintain its integrity in the face of harsh conditions makes it a crucial component in numerous heating systems.

|

|

Tungsten Heating Wire Functions

- High-Temperature Resistance: With a maximum operating temperature of 2500°C, it sustains stability in demanding heating environments.

- Low Thermal Expansion: Ensures dimensional stability and reliability during thermal cycles.

- High Electrical Resistivity: Facilitates efficient energy conversion and heat generation.

Product Applications

Tungsten heating wire finds extensive utility across various industries:

- Industrial Furnaces:These heating elements are crucial for maintaining consistent temperatures in vacuum and high-temperature furnaces, ensuring reliable performance and longevity in critical industrial processes.

- Semiconductor Manufacturing:These components are integral to the manufacturing process of silicon wafers and the fabrication of integrated circuits, playing a vital role in the semiconductor industry by facilitating the creation of high-quality, precision-engineered microelectronic devices.

- Medical Devices: These elements are pivotal for achieving accurate thermal regulation in medical equipment, ensuring the safety and efficacy of treatments. They are meticulously crafted through a robust production process and state-of-the-art manufacturing techniques to meet the stringent standards required in healthcare applications.

|

|

Production Process and Manufacturing

Our state-of-the-art facilities integrate advanced technologies:

- Equipment: Our range of equipment encompasses sophisticated machinery such as intermediate frequency sintering furnaces for advanced material processing, vacuum arc melting furnaces for creating high-purity metals, and CNC (Computer Numerical Control) machinery for precision engineering and manufacturing excellence.

- Quality Assurance: Our commitment to excellence is reflected in the rigorous testing protocols and ongoing material research we conduct, ensuring that our products consistently meet and often exceed international standards for quality, reliability, and safety.

|

|

|

Why Choose Us?

Shaanxi Peakrise Metal Co., Ltd. distinguishes itself with:

- Comprehensive Expertise: Over a decade of experience in non-ferrous metal production and innovation.

- Global Reach: Trusted partnerships across Taiwan, Ukraine, USA, and beyond, reflecting our commitment to quality and service excellence.

- Customization: Dedicated OEM services tailored to meet specific client requirements.

|

|

OEM Services

Our customization services are tailored to meet the unique demands of various industries, providing a comprehensive solution that aligns seamlessly with the specific requirements of our esteemed clients.

|

|

FAQs

- What is the maximum temperature tolerance of the product?

- Tungsten X- Ray Tube can withstand temperatures up to 2500°C.

- What industries commonly use the tungsten heating wire?

- It is prevalent in semiconductor manufacturing, aerospace, and medical device sectors.

- How is the product packaged for international shipping?

- We employ robust wooden crates, moisture-resistant packaging, and conform to international shipping standards.

Packaging and Logistics

- Packaging: Secure wooden crates, moisture-proof materials, and customized packaging options.

- Logistics: Efficient handling through sea, air, and land freight, ensuring timely delivery worldwide.

|

|

|

|

|

|

|

|

|

|

Contact us

Contact us today to explore how our superior tungsten heating wire solutions can elevate your industrial applications. Email us at info@peakrisemetal.com for inquiries and collaborations.