customized tantalum sputtering target

Material: Tantalum/Tantalum Alloy

Purity : 99.95%,99.99%

Density: ≥16.67g/cm3

Thickness: 0.03~50mm

Standard: ASTM B708

Quality: Third Party Test Report

Type: Manufacturer

Standard: RO5200,RO5252,RO5255

Delivery status: Annealed (M)

PRODUCT DESCRIPTION

Customized Tantalum Sputtering Target Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of customized tantalum sputtering target. With a commitment to excellence and precision, we specialize in providing tailored solutions that meet the exacting demands of global industries.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Tantalum (Ta) |

| Purity | 99.95% min |

| Density | 16.6 g/cm³ |

| Grain Size | < 100 μm |

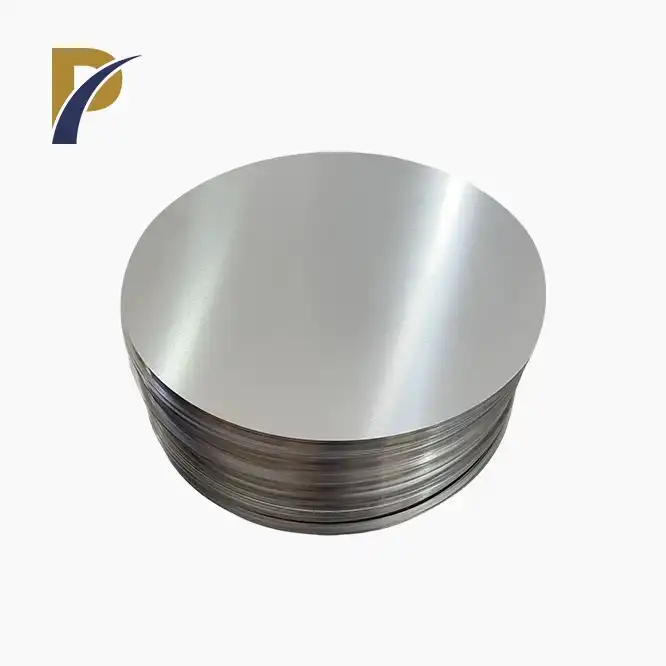

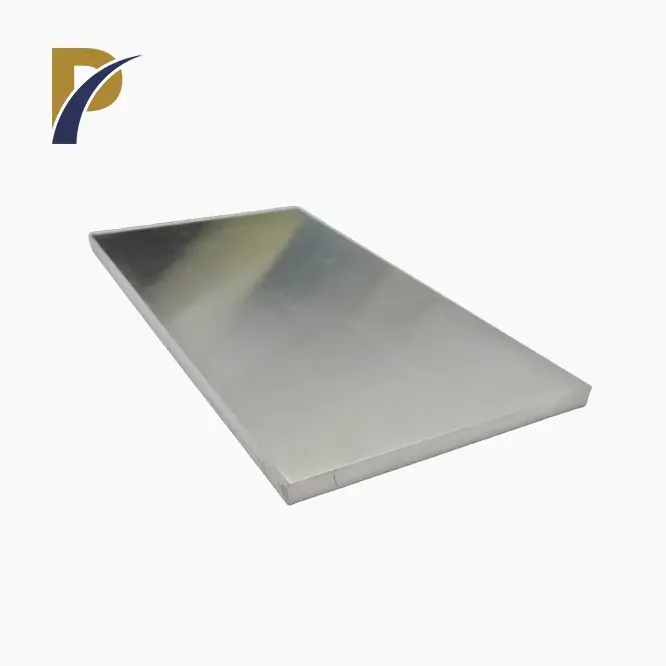

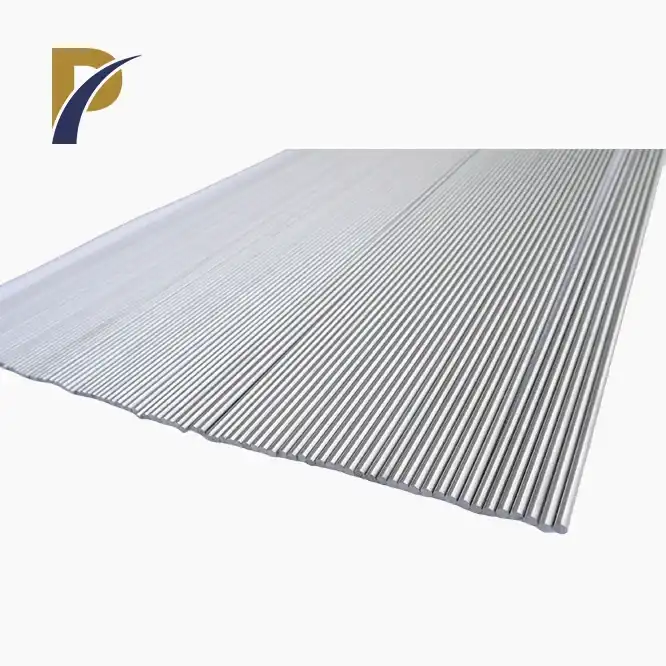

| Shape | Disc, Plate, Customized |

| Dimensions | Customized |

| Surface Finish | Ra ≤ 1.6 μm |

| Target Bonding | Indium, Elastomer, Backing Plate |

| Customization Options | Dimensions, Purity, Shape, Surface Finish |

|

|

Physical and Chemical Properties

High-Strength Titanium Pipe and Tube exhibits high thermal conductivity, excellent corrosion resistance, and exceptional purity, making them ideal for advanced thin film applications in semiconductor and solar industries.

|

|

Customized Tantalum Sputtering Target Features

High-Strength Titanium Pipe and Tube is custom-made items intended for explicit applications in cutting edge slight film affidavit processes. Here are the vital elements and advantages of customized tantalum sputtering target:

- Accuracy Designing: It is designed with accuracy to meet careful particulars, including aspects, structure, and immaculateness levels. This customization guarantees ideal execution and similarity with sputtering frameworks.

- High Virtue Levels: It is produced with high immaculateness tantalum, normally surpassing 99.95%. This virtue is pivotal for guaranteeing uniform testimony and limiting contaminations that could influence film quality.

- Superb Warm Conductivity: Tantalum displays brilliant warm conductivity, working with effective intensity dissemination during the sputtering system. This property keeps up with stable statement conditions and improves film consistency.

- Compound Opposition: Tantalum is profoundly impervious to consumption by acids and offers great similarity with different sputtering gases and conditions. This opposition guarantees life span and unwavering quality in forceful testimony conditions.

- Adaptable Aspects and Shapes: Makers can alter the product to meet explicit prerequisites with respect to measure, shape, and design. This adaptability considers customized arrangements that fit different sputtering chamber plans and applications.

- Predictable and Dependable Execution: Each product goes through thorough quality control measures to guarantee consistency in thickness, thickness, and in general execution. This unwavering quality is basic for accomplishing reproducible flimsy film properties after some time.

- Expansive Application Flexibility: It finds applications in a large number of enterprises, including semiconductor fabricating, optical coatings, aviation, and clinical gadget creation. They are fundamental for keeping tantalum-based films with exact qualities required for cutting edge innovations.

- Natural and Wellbeing Security: Tantalum is biocompatible and non-poisonous, making it appropriate for applications where security and ecological contemplations are vital, like in clinical gadget coatings.

Product Applications

- Semiconductor Manufacturing: Crucial for thin film deposition in integrated circuits.

- Solar Photovoltaics: Enables efficient solar cell production.

- Optical Coatings: Ensures precision in optical device manufacturing.

|

|

Production Process

Our advanced facilities include vacuum arc melting furnaces, precision machining tools, and stringent quality control measures, ensuring every Titanium Pipe and Tube meets global standards.

Our Factory

Located in Shaanxi, China, our state-of-the-art facility combines research, development, and manufacturing to deliver innovative non-ferrous metal solutions worldwide.

|

|

|

Logistics and Packaging

- Packaging: Secure wooden crates, moisture-resistant packaging.

- Shipping: Sea freight, air freight, multimodal transport, courier services.

|

|

|

Why Choose Us

- Extensive Industry Experience: Over a decade of supplying high-quality non-ferrous metal products.

- Customization Expertise: Tailored solutions to meet specific customer requirements.

- Global Reach: Exporting to Taiwan, Ukraine, USA, and beyond, with a strong reputation for reliability.

|

OEM Services

We specialize in Titanium Pipe and Tube to exact specifications, ensuring compatibility with diverse deposition systems.

|

|

FAQ

- What is the typical lead time for customized customized tantalum sputtering target orders?

- Lead times vary based on specifications, generally ranging from 2 to 4 weeks.

- Do you provide technical support for target installation?

- Yes, we offer comprehensive technical assistance to optimize target performance.

- Can you manufacture targets with specific doping elements?

- Absolutely, we can incorporate various dopants per customer requirements.

- What quality certifications do you hold?

- We adhere to ISO 9001 standards and can provide material certificates upon request.

- Do you offer volume discounts for large orders?

- Yes, we provide competitive pricing for bulk purchases.

Contact us

Explore our range of customized tantalum sputtering target and partner with Shaanxi Peakrise Metal Co., Ltd. for your next project. Contact us at info@peakrisemetal.com to discuss your requirements.