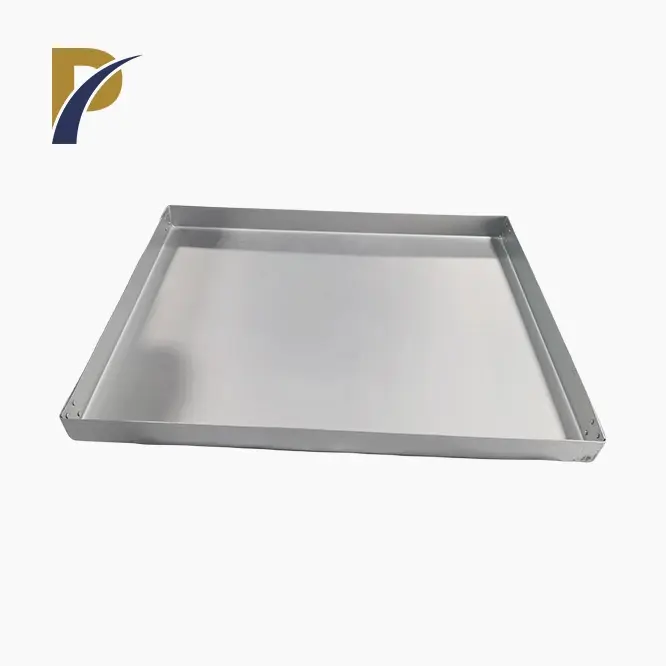

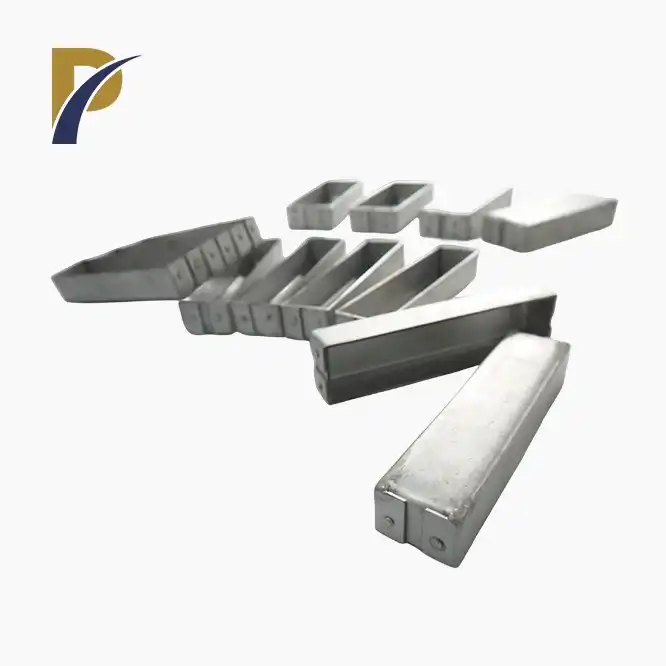

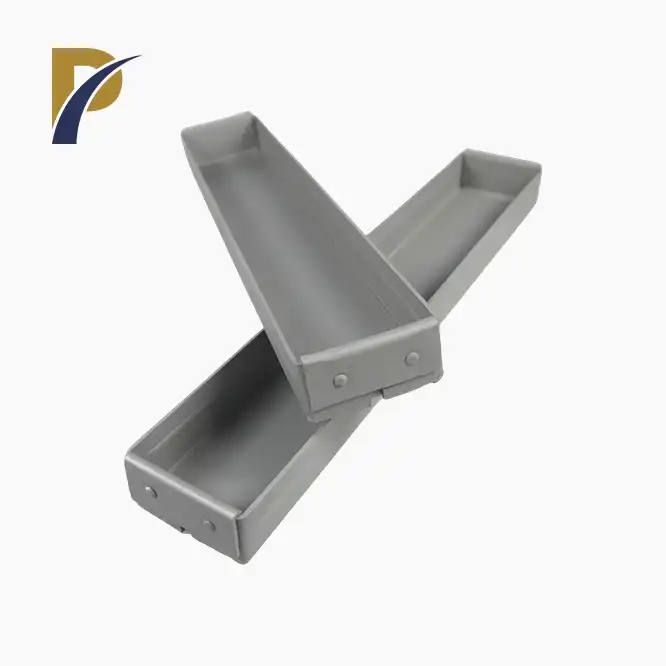

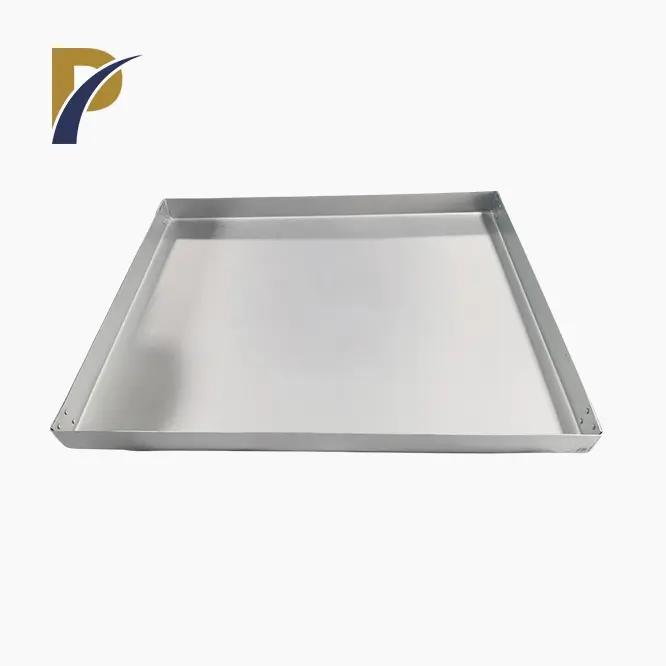

molybdenum riveted boat

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Introduction To Molybdenum Riveted Boat

In high-temperature applications, particularly in the metallurgical and substance industries, molybdenum riveted boat is essential components. These boats are made of molybdenum, a refractory metal that is known for its high thermal and electrical conductivity, high temperature resistance, and low thermal expansion. Shaanxi Peakrise Metal Co., Ltd., a major supplier of this products, ensures that our products are of the highest quality and performance with years of experience and innovative ideas. Because our boats are built to withstand extreme conditions, they are ideal for cycles like sintering, strengthening, and metal vanishing.

Product Parameters

| Parameter | Value |

|---|---|

| Purity | ≥ 99.95% Mo |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Maximum Operating Temperature | 1800°C |

| Dimensions (LxWxH) | Customizable |

| Rivet Material | Pure Molybdenum |

|

|

|

Physical and Chemical Properties

- Density: 10.2 g/cm³

- Melting Point: 2620°C

- Thermal Conductivity: 138 W/m·K

- Coefficient of Thermal Expansion: 4.8 µm/m·K

- Electrical Resistivity: 5.2 µΩ·cm

|

|

Product Functions

- High-Temperature Resistance: Molybdenum riveted boat can operate effectively at temperatures up to 1800°C, maintaining structural integrity and performance.

- Thermal Conductivity: Excellent thermal conductivity ensures uniform heat distribution, crucial for processes like metal evaporation.

- Corrosion Resistance: The boats exhibit high resistance to corrosion and oxidation, even under extreme conditions, ensuring longevity.

- Mechanical Strength: The riveted construction provides additional mechanical strength and durability, ideal for high-stress applications.

Product Applications

- Metallurgical Industry: Used in high-temperature processes such as sintering and annealing of metals and alloys.

- Chemical Industry: Ideal for reactions requiring high-purity environments, ensuring no contamination.

- Electronics Industry: Employed in the production of thin-film materials through evaporation processes.

- Glass Manufacturing: Used in melting and refining glass due to their high melting point and durability.

|

|

Product Manufacturing Process

- Raw Material Selection: High-purity molybdenum is selected to ensure the highest quality.

- Forming: The molybdenum is formed into boat shapes using advanced rolling and drawing techniques.

- Riveting: The boats are riveted using pure molybdenum rivets to enhance structural integrity.

- Quality Control: Each boat undergoes rigorous testing for purity, dimensions, and performance to ensure it meets our stringent standards.

|

|

|

Our Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. is a seasoned enterprise specializing in the production of refractory and non-ferrous metals. Our state-of-the-art facilities include intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, and more. With a commitment to quality and innovation, we provide high-standard products and services to clients worldwide.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

Packaging Options:

- Wooden Crates

- Cardboard Boxes

- Foam Inserts

- Moisture-Proof and Waterproof Packaging

- Customized Packaging

- International Standard Compliant Packaging

|

|

|

|

|

|

|

|

|

|

Logistics Options:

- Sea Freight

- Air Freight

- Land Transport

- Multimodal Transport

- Courier Services

Why Choose Us

- Extensive Experience: Over a decade of expertise in non-ferrous metal production.

- Quality Assurance: Rigorous quality control processes to ensure top-notch products.

- Global Reach: Exporting to numerous countries with long-term customer relationships.

- Advanced Equipment: Cutting-edge production and testing facilities.

- Customization: Tailored solutions to meet specific customer requirements.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services, allowing clients to customize molybdenum riveted evaporation boats to their exact specifications. Our team works closely with clients to develop products that meet their unique needs.

|

|

Frequently Asked Questions

1.What is the purity of the molybdenum used in your riveted boats?

-Our riveted molybdenum boats are made with molybdenum of ≥ 99.95% purity.

2.Can you customize the dimensions of the molybdenum riveted boats?

-Yes, we offer customizable dimensions to meet your specific requirements.

3.What is the maximum operating temperature for these boats?

-The maximum operating temperature is 1800°C.

4.How do you ensure the quality of your molybdenum riveted boats?

-We conduct rigorous quality control tests, including purity, dimensional accuracy, and performance testing.

5.Do you provide international shipping?

-Yes, we offer various logistics options, including sea freight, air freight, and courier services, to deliver our products globally.

Contact Us

For high-quality molybdenum riveted boat and outstanding client care, contact Shaanxi Peakrise Metal Co., Ltd. today. Our group is prepared to help you with your necessities and give altered answers for meet your prerequisites. Email us at info@peakrisemetal.com to get in touch.