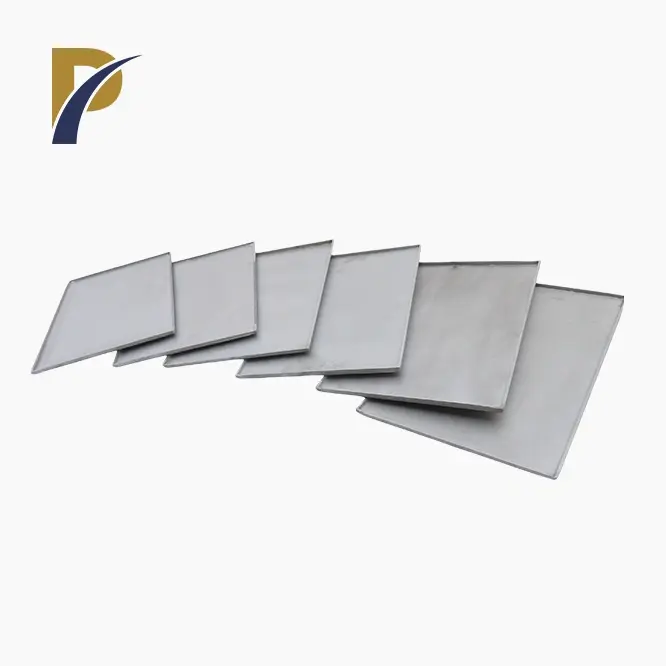

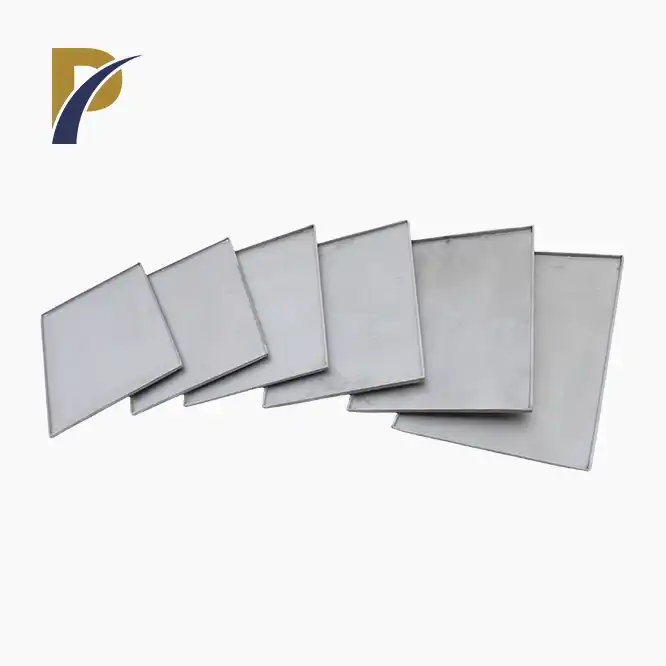

molybdenum sintering boats

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Molybdenum Sintering Boats Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of molybdenum sintering boats. We specialize in providing high-quality solutions for the global market, leveraging our expertise in non-ferrous metal production.

Product Specifications

| Property | Value |

|---|---|

| Material | Molybdenum |

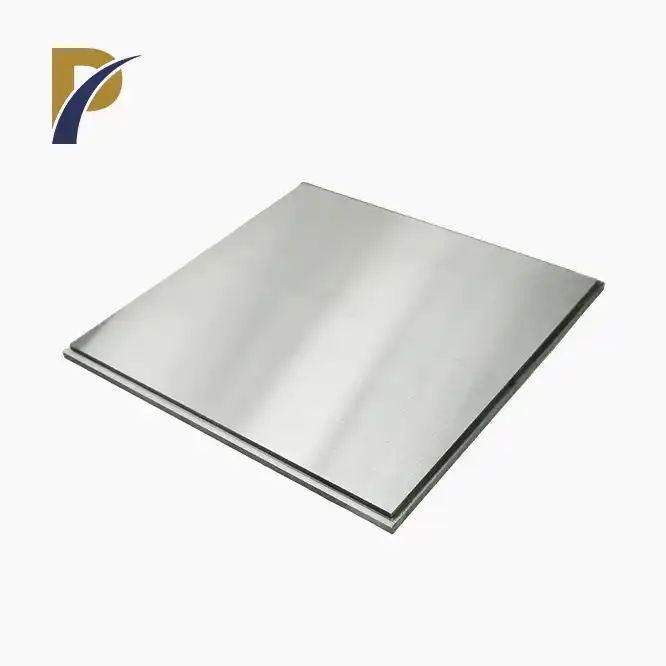

| Purity | 99.95% min |

| Density | 10.2 g/cm³ |

| Melting Point | 2,623°C (4,753°F) |

| Dimensions | Customizable |

| Surface Finish | Smooth |

| Temperature Range | Up to 1,800°C (3,272°F) |

| Application | Sintering of metals |

| OEM Services | Available |

| Packaging Options | Customizable |

| Logistics | Worldwide shipping |

|

|

Physical and Chemical Properties

Molybdenum Sintering Boats are known for their high melting point, excellent thermal conductivity, and resistance to oxidation at high temperatures. They are ideal for use in controlled atmosphere environments due to their robustness and durability.

|

|

Product Features

- High Temperature Resistance: Withstanding temperatures up to 1,800°C, suitable for various sintering applications.

- Uniform Heating Distribution: Ensures consistent heat transfer across the material being sintered.

- Chemical Inertness: Maintains purity of the sintering process without contamination.

- Customizable Designs: Tailored to meet specific customer requirements.

- Long Lifespan: Durable construction for extended usability.

Applications

The utilization of molybdenum sintering boats spans across critical sectors such as semiconductor manufacturing, powder metallurgy, heat treatment processes, and the ceramic and glass industries. These boats play a pivotal role in enabling precise and controlled sintering processes, thereby significantly enhancing both product quality and production efficiency across diverse industrial applications.

In semiconductor manufacturing, the products are essential for the production of silicon wafers and other semiconductor materials. They provide a stable and inert environment necessary for the sintering of delicate components, ensuring the integrity and performance of the final products.

Within powder metallurgy, these boats facilitate the consolidation of powdered metals under high temperatures and pressures, enabling the creation of complex and durable components. The controlled atmosphere they offer helps prevent oxidation and contamination during the sintering process, crucial for achieving desired material properties.

In heat treatment processes, Sintered Molybdenum Boats serve as reliable containers for annealing and sintering operations. Their high melting point and resistance to thermal shock make them ideal for withstanding the extreme temperatures required to modify the physical and mechanical properties of metals.

Moreover, in the ceramic and glass industries, these boats are utilized for firing and annealing applications. They ensure uniform heating and cooling cycles, which are vital for achieving consistent product quality and minimizing defects in finished ceramics and glassware.

Overall, the products play a multifaceted role across these industries, offering indispensable support in achieving precise sintering conditions that optimize productivity and uphold stringent quality standards.

|

|

Production Process

At Shaanxi Peakrise Metal Co., Ltd., we utilize advanced equipment including intermediate frequency sintering furnaces and vacuum arc melting furnaces to ensure the highest quality standards in manufacturingthe product.

|

|

|

Our Factory

Our facilities are equipped with state-of-the-art machinery for machining, welding, and finishing, allowing us to deliver precision-engineered products to global clients.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging: We offer secure packaging options such as wooden crates, cardboard boxes, and custom foam filling to ensure safe transit and storage.

Logistics: We provide flexible shipping solutions including sea freight, air freight, land transportation, and expedited services to meet diverse customer needs worldwide.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Comprehensive Expertise: Over a decade of experience in non-ferrous metal production.

- Global Reach: Trusted by clients worldwide including Taiwan, Ukraine, USA, and more.

- Customization: We offer tailored solutions to meet specific project requirements.

- Quality Assurance: Rigorous testing and material certification ensure product reliability.

- Customer Satisfaction: Long-term partnerships based on quality and service excellence.

|

OEM Services

We specialize in OEM/ODM services, collaborating closely with clients to develop custom solutions that meet unique specifications and applications.

|

|

FAQ

- What is the typical lead time for orders?

- Lead times vary based on order volume and customization requirements.

- Can you provide material certifications?

- Yes, we provide material certificates as per industry standards.

- Do you offer sample orders?

- Yes, sample orders can be arranged upon request.

- What are the payment terms accepted?

- We accept various payment methods; specifics can be discussed with our sales team.

- Are your products compliant with international quality standards?

- Yes, our products meet stringent quality and regulatory requirements.

Contact Us

Ready to enhance your manufacturing processes with our molybdenum sintering boats? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com to discuss your requirements and begin a partnership that ensures superior quality and performance.

YOU MAY LIKE

-

VIEW MOREmolybdenum evaporation boats

VIEW MOREmolybdenum evaporation boats -

VIEW MOREmolybdenum riveted boat

VIEW MOREmolybdenum riveted boat -

VIEW MOREmolybdenum lanthanum furnace boats

VIEW MOREmolybdenum lanthanum furnace boats -

VIEW MOREmolybdenum vacuum boat

VIEW MOREmolybdenum vacuum boat -

VIEW MOREmolybdenum glass melting electrodes

VIEW MOREmolybdenum glass melting electrodes -

VIEW MORElanthanated molybdenum plate

VIEW MORElanthanated molybdenum plate -

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MOREtungsten rods

VIEW MOREtungsten rods