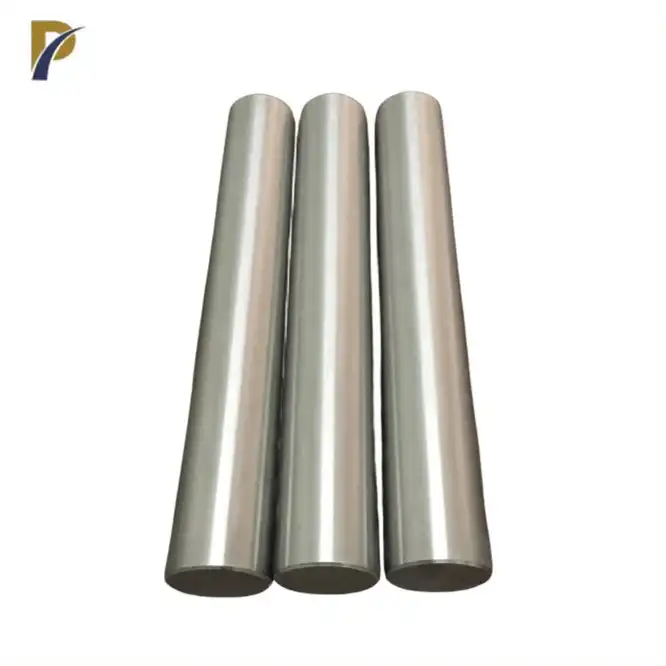

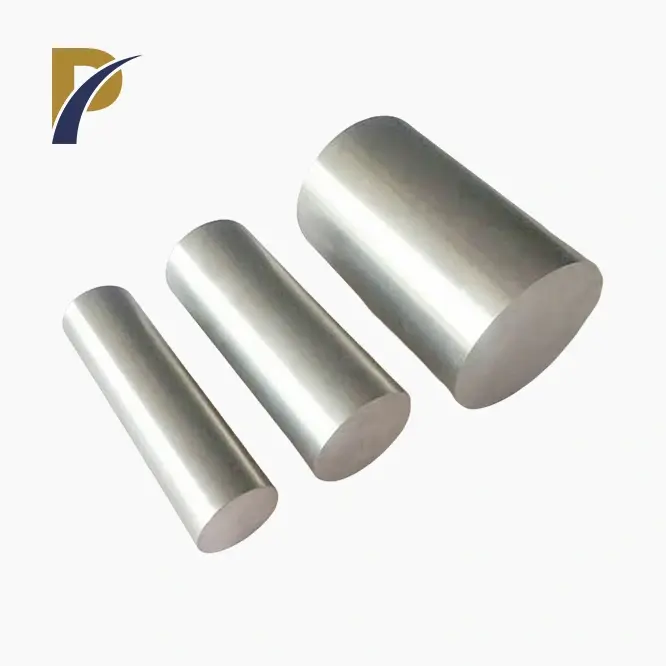

molybdenum high temperature alloy tzm rod

Diameter: 2-200mm

Length: 10-250mm

Density: 10.22g·cm-3

Elongation: 20%

Melting Point : 2617℃

Yield Strength: 560~1150MPa

Tensile Strength: 685MPa

Resistivity: (5.3~5.5)X10-8 Ω·m

Standard: ASTM B387

PRODUCT DESCRIPTION

Product Introduction: molybdenum high temperature alloy tzm rod

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of high-quality molybdenum high temperature alloy tzm rod. As a leading manufacturer in the non-ferrous metal industry, we specialize in providing advanced materials that meet the stringent demands of high-temperature applications worldwide.

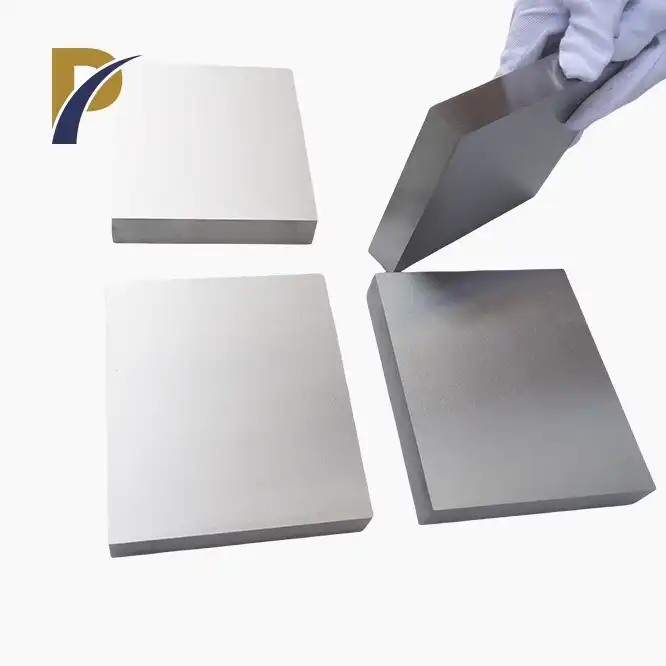

Shaanxi Peakrise Metal Co., Ltd. and TZM Rods, the non-ferrous metals tungsten, molybdenum, tantalum, niobium, titanium, zirconium, nickel, and more are just a few of the many that Shaanxi Peakrise Metal Co., Ltd. manufactures. We have a distinguished reputation for providing superior quality and exceptional customer service thanks to our more than ten years of production and international trade expertise.

Product Parameters

| Property | Value |

|---|---|

| Composition | TZM (Titanium-Zirconium-Molybdenum alloy) |

| Density | 10.1 g/cm³ |

| Melting Point | 2,623°C (4,753°F) |

| Tensile Strength | 1050 MPa |

| Yield Strength | 940 MPa |

| Elongation | 10% |

| Hardness | 250 HB |

|

|

|

Physical and Chemical Properties

High-Temperature TZM Rod exhibit exceptional mechanical strength and thermal stability, making them ideal for applications requiring high temperature resistance and dimensional stability under severe conditions.

|

|

Product Features

- High Temperature Resistance: Molybdenum high temperature alloy tzm rod maintain mechanical strength at temperatures above 1300°C.

- Excellent Creep Resistance: Ideal for prolonged use under high-stress conditions.

- Good Thermal and Electrical Conductivity: Ensures efficient heat dissipation and electrical properties.

- Corrosion Resistance: Suitable for use in aggressive environments.

Product Applications

High-Temperature TZM Rod finds extensive applications across various industries:

- Aerospace: Used in rocket nozzles, and re-entry vehicle components.

- Defense: Critical components in missile systems and high-performance aircraft.

- Electronics: Crucial for high-temperature furnace components and semiconductor production.

|

|

Manufacturing Process

Our cutting-edge facilities at Shaanxi Peakrise Metal Co., Ltd. include vacuum arc melting furnaces, intermediate frequency sintering furnaces, and precision machining equipment. We can produce TZM rods of the highest quality, precisely tailored to meet the specific requirements of our customers, thanks to these cutting-edge capabilities.

For optimal material properties in TZM Molybdenum High Temperature Rod, our intermediate frequency sintering furnaces guarantee uniform heating and controlled sintering processes. Additionally, our vacuum arc melting furnaces make it possible to produce alloys of extremely high purity, which are necessary for applications that demand superior performance and dependability.

|

|

|

Why Choose Us?

- Comprehensive Expertise: Over a decade of specialization in non-ferrous metals.

- Quality Assurance: Rigorous testing and inspection protocols.

- Global Reach: Established partnerships across Taiwan, Ukraine, South Korea, the USA, and more.

- Customization: Tailored solutions to meet specific customer requirements.

|

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers flexible OEM services, accommodating unique specifications and design requirements to meet diverse industry needs.

|

|

FAQs

-

What is the TZM Molybdenum High Temperature Rod composed of?

- TZM rods consist of titanium, zirconium, and molybdenum, enhancing their mechanical properties.

-

What are the typical applications of TZM rods?

- They are commonly used in aerospace, defense, and electronics industries for their high temperature resistance.

-

Can TZM rods withstand corrosive environments?

- Yes, TZM rods exhibit excellent corrosion resistance.

-

Do you provide certifications for your TZM rods?

- Yes, we offer certifications for material composition, mechanical properties, and quality standards.

-

What packaging options do you offer?

- We provide wooden crates, cardboard boxes, and custom packaging to ensure safe delivery.

Packaging and Logistics

Packaging:

- Wooden crates

- Cardboard boxes

- Customized packaging

Logistics:

- Sea freight

- Air freight

- Land transportation

- Express delivery services

|

|

|

|

|

|

|

|

|

|

Contact Us

For inquiries about molybdenum high temperature alloy tzm rod or to discuss your specific requirements, please contact us at info@peakrisemetal.com. Partner with Shaanxi Peakrise Metal Co., Ltd. for superior quality and service.