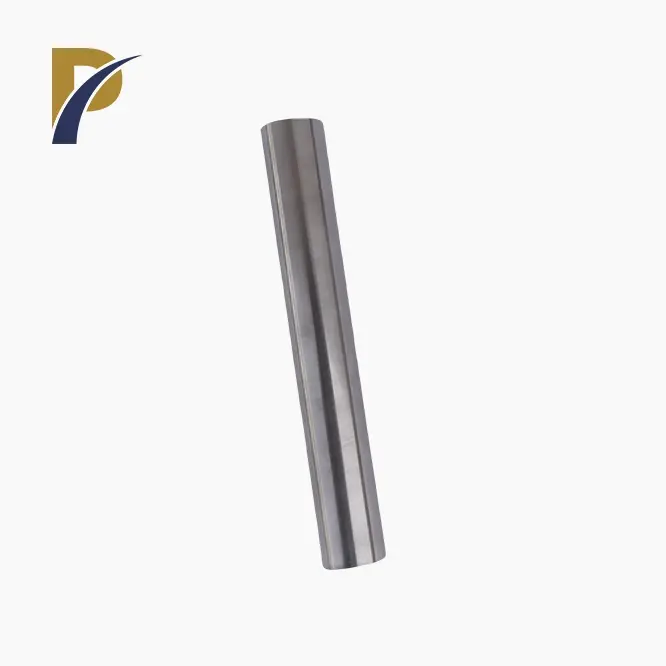

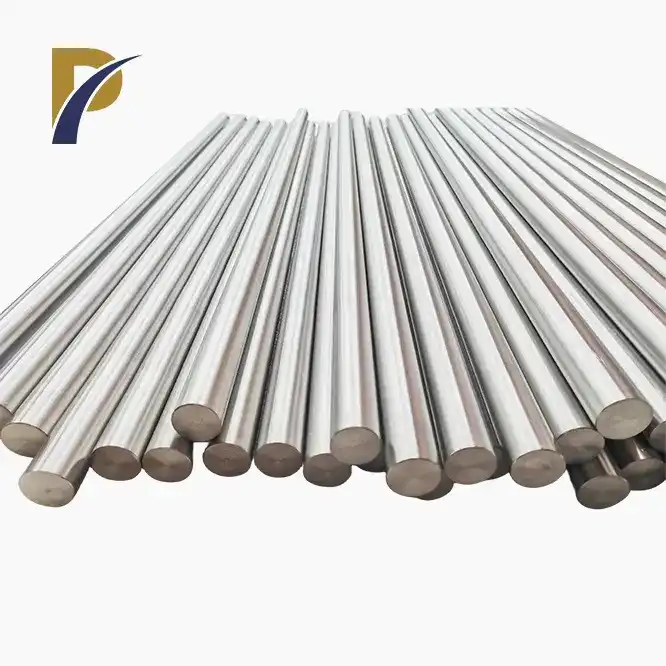

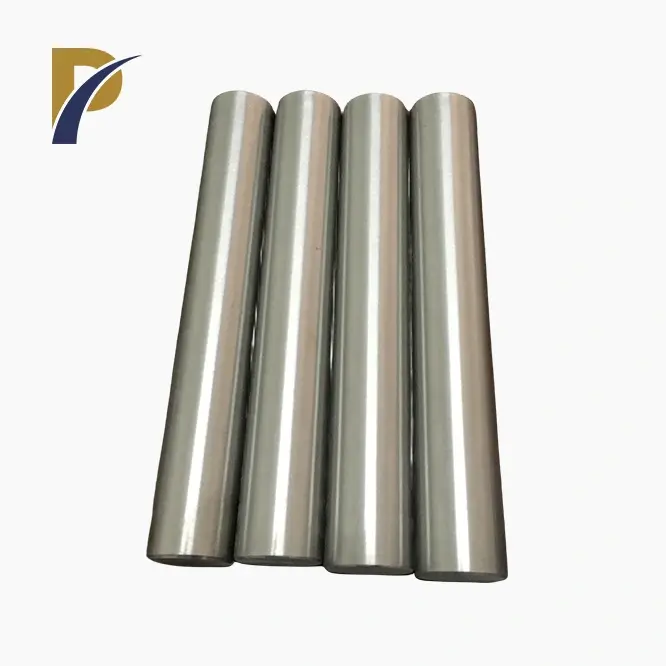

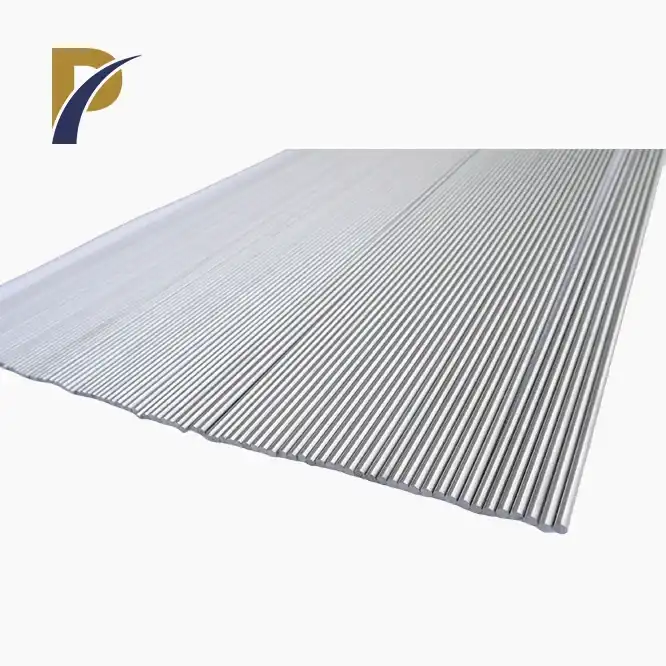

tzm molybdenum alloy rod

Diameter: 2-200mm

Length: 10-250mm

Density: 10.22g·cm-3

Elongation: 20%

Melting Point : 2617℃

Yield Strength: 560~1150MPa

Tensile Strength: 685MPa

Resistivity: (5.3~5.5)X10-8 Ω·m

Standard: ASTM B387

PRODUCT DESCRIPTION

tzm molybdenum alloy rod Introduction

Shaanxi Peakrise Metal Co., Ltd. proudly offers TZM molybdenum alloy rod, engineered for excellence in extreme high-temperature environments. TZM, an alloy consisting of 0.5% Titanium, 0.08% Zirconium, and 0.02% Carbon, with molybdenum as its base, is renowned for its superior mechanical properties and thermal stability. As a leading supplier of molybdenum and its alloys, Peakrise Metal delivers high-quality TZM rods that meet the demanding needs of industries requiring resilience against high temperatures and wear.

TZM Alloy Molybdenum Rod is integral to various high-tech applications due to their exceptional properties, including high melting points, excellent creep resistance, and robust thermal conductivity. Our rods are precision-engineered to provide unparalleled performance in applications such as aerospace, electronics, and industrial processes where durability and reliability are critical.

Product Parameters

| Parameter | Value |

|---|---|

| Material | TZM Molybdenum Alloy |

| Diameter Range | 5 mm - 50 mm |

| Length | Up to 2000 mm |

| Tensile Strength | 350 MPa |

| Yield Strength | 300 MPa |

| Melting Point | 2620°C |

| Thermal Conductivity | 138 W/m·K |

| Density | 10.2 g/cm³ |

| Hardness | 200 HV |

|

|

Physical and Chemical Properties

Melting Point: 2620°C

Density: 10.2 g/cm³

Thermal Conductivity: 138 W/m·K

Tensile Strength: 350 MPa

Yield Strength: 300 MPa

Hardness: 200 HV

These properties make it highly suitable for high-temperature applications where conventional materials may fail.

|

|

TZM Molybdenum Alloy Rod Functions

High-Temperature Resistance: TZM molybdenum alloy rod maintain structural integrity and performance at temperatures exceeding 2500°C, making them ideal for use in high-temperature furnaces and reactors.

Creep Resistance: The alloy exhibits minimal deformation under prolonged high-temperature stress, ensuring longevity and reliability in extreme conditions.

Thermal Conductivity: Effective heat transfer capabilities make these rods suitable for applications requiring efficient thermal management.

Mechanical Strength: Enhanced mechanical properties contribute to superior durability and resistance to wear, extending the lifespan of components in harsh environments.

TZM Molybdenum Alloy Rod Applications

Aerospace Industry: TZM rods are used in rocket nozzles, jet engine components, and high-performance bearings due to their ability to withstand extreme temperatures and pressures.

Electronics Manufacturing: The rods serve as components in high-temperature vacuum furnaces and sputtering targets, crucial for producing semiconductors and other electronic devices.

Industrial Processes: Molybdenum TZM Alloy Rod is utilized in various high-temperature processes, including glass melting and metal smelting, where their durability ensures efficient operation.

Research and Development: Their high melting point and mechanical strength make TZM rods essential for experimental setups requiring extreme conditions.

|

|

Production Process

Material Preparation: Molybdenum powder is alloyed with titanium, zirconium, and carbon in precise proportions.

Sintering: The alloy mixture is sintered at high temperatures to achieve optimal density and strength.

Extrusion: The sintered material is extruded into rod shapes under controlled conditions.

Machining: Precision machining is employed to achieve the desired dimensions and surface finish.

Quality Control: Rigorous testing ensures that each rod meets the high standards required for specific applications.

|

|

|

Company Overview

Shaanxi Peakrise Metal Co., Ltd. is a distinguished producer of non-ferrous metals and alloys, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. With extensive experience in manufacturing and processing, we offer a wide range of high-quality products tailored to diverse industrial needs. Our facilities are equipped with advanced production technologies, ensuring top-notch quality and performance. Our products are exported globally, establishing us as a trusted supplier in the international market.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

Wooden Crates: For secure transportation and storage.

Cardboard Boxes: Lightweight and cost-effective for smaller quantities.

Foam Padding: Provides additional protection against damage.

Waterproof and Moisture-Proof Packaging: Ensures product integrity in various climates.

Custom Packaging: Tailored solutions based on customer requirements.

International Standards: Packaging complies with global shipping standards.

Logistics

Sea Freight: Reliable and economical for large shipments.

Air Freight: Fast delivery for urgent orders.

Land Transport: Efficient for regional distribution.

Multimodal Transport: Combining different transport modes for optimized logistics.

Courier Services: For expedited delivery of smaller quantities.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Extensive Experience: Over a decade of expertise in non-ferrous metal production.

High-Quality Products: Rigorous quality control and advanced manufacturing processes.

Global Reach: Established relationships with customers in numerous countries.

State-of-the-Art Equipment: Advanced technology for precise production.

Customer-Centric Service: Customizable solutions and dedicated support.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers OEM and ODM services to meet specific customer requirements. We provide custom processing and production tailored to your needs, ensuring high-quality results and satisfaction.

|

|

FAQ

- What is TZM molybdenum alloy? TZM is a high-performance alloy containing molybdenum, titanium, zirconium, and carbon, known for its superior high-temperature and mechanical properties.

- What applications are suitable for TZM molybdenum rods? tzm molybdenum alloy rod are used in aerospace, electronics manufacturing, industrial processes, and research applications requiring high-temperature resistance and mechanical strength.

- What is the maximum operating temperature for TZM rods? TZM molybdenum rods can operate at temperatures up to 2500°C.

- Can TZM rods be customized? Yes, we offer OEM and ODM services to tailor TZM rods to specific requirements.

- How is the quality of TZM molybdenum rods ensured? Quality is ensured through rigorous testing, advanced production technologies, and adherence to international standards.

Contact Us

For premium TZM molybdenum alloy rod and exceptional service, reach out to Shaanxi Peakrise Metal Co., Ltd. today. We are ready to meet your high-performance material needs and provide tailored solutions for your industry. Contact us at info@peakrisemetal.com to discuss your requirements and place your order.

YOU MAY LIKE

-

VIEW MOREmolybdenum high temperature alloy tzm rod

VIEW MOREmolybdenum high temperature alloy tzm rod -

VIEW MOREtungsten tig rods

VIEW MOREtungsten tig rods -

VIEW MOREsic rod heater element

VIEW MOREsic rod heater element -

VIEW MOREtitanium pipe and fittings

VIEW MOREtitanium pipe and fittings -

VIEW MOREtungsten and molybdenum alloy plate

VIEW MOREtungsten and molybdenum alloy plate -

VIEW MOREmolybdenum sintering boats

VIEW MOREmolybdenum sintering boats -

VIEW MOREcustomized tantalum sputtering target

VIEW MOREcustomized tantalum sputtering target -

VIEW MOREwelding titanium tube

VIEW MOREwelding titanium tube