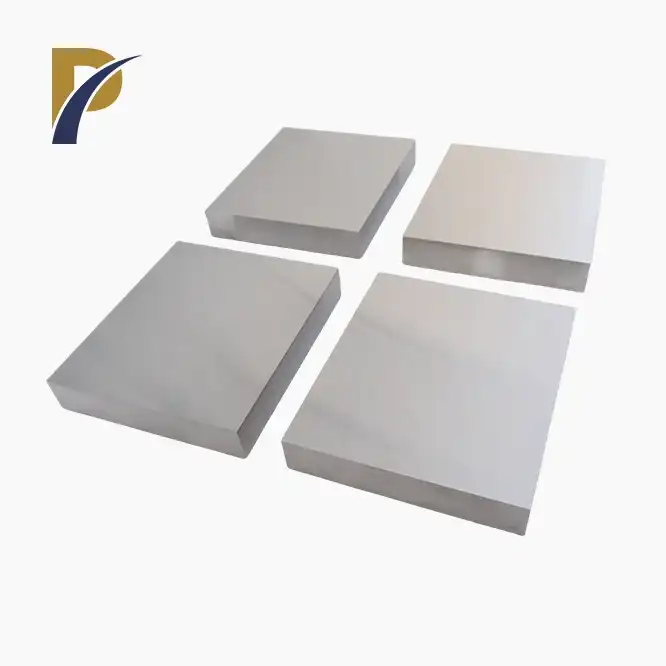

molybdenum alloy strip foil

Material: Molybdenum And Molybdenum Alloy

Grade: Mo1,TZM,Mo-La

Purity : 99.95%

Density: 10.2g/cm3

Thickness: 0.03~1.0mm

Width: 20~300mm

Use Temperture: 1100~1800℃

Surface: Bright

Application: specialty steels. Molybdenum electrodes, vacuum furnace applications, nuclear power, missiles, and airplane parts.

PRODUCT DESCRIPTION

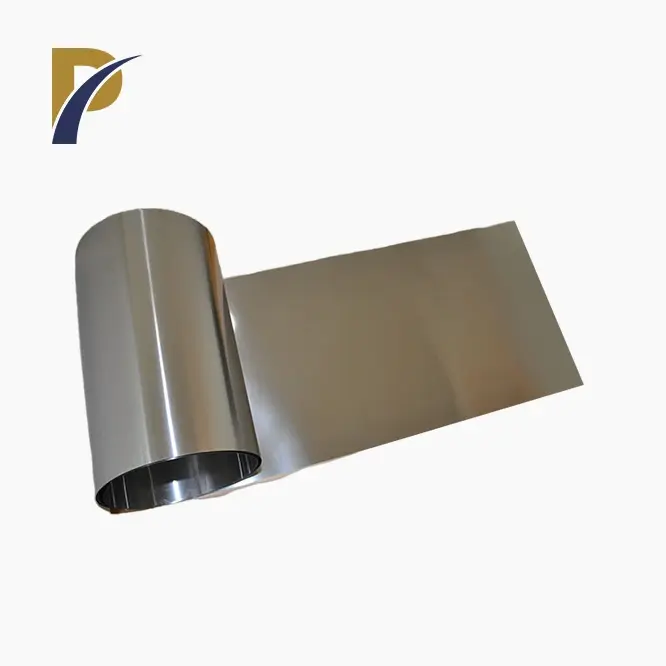

Molybdenum Alloy Strip Foil Product Introduction

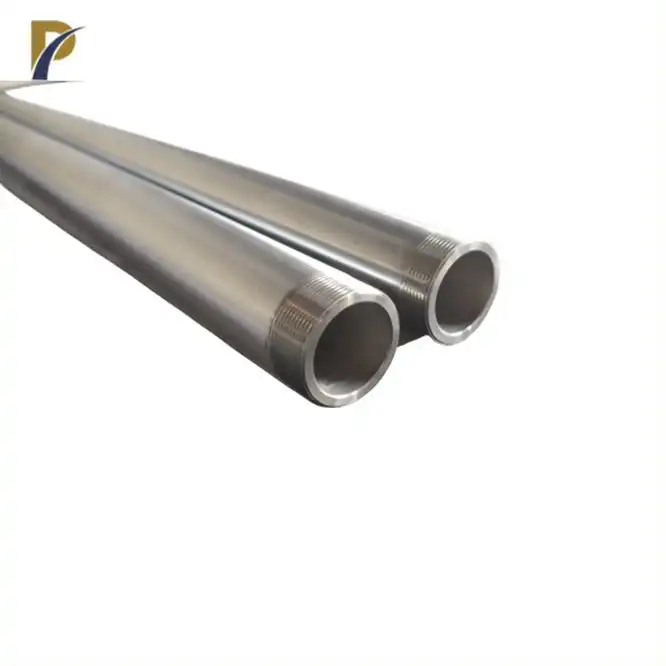

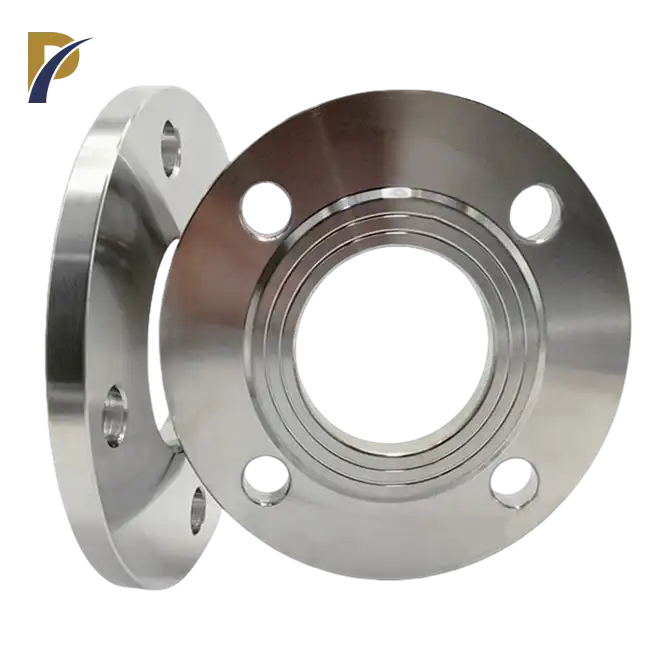

Molybdenum alloy strip foil is a versatile and essential material in various high-technology industries.Molybdenum compound is generally utilized in gadgets, aviation, and military applications because of its high softening point, uncommon warm conductivity, and fantastic mechanical properties.

As a leading supplier of the product, Shaanxi Peakrise Metal Co., Ltd. prides itself on delivering high-quality, reliable products that meet the stringent requirements of our global clientele. Our Molybdenum Alloy Strip is manufactured with precision and care, ensuring superior performance in demanding environments.

Product Parameters

| Parameter | Value |

|---|---|

| Purity | ≥ 99.95% |

| Density | 10.2 g/cm³ |

| Thickness | 0.01 mm – 0.1 mm |

| Width | 10 mm – 300 mm |

| Tensile Strength | 690 MPa |

| Parameter | Value |

|---|---|

| Thermal Conductivity | 138 W/m·K |

| Melting Point | 2620°C |

| Electrical Conductivity | 34% IACS |

| Elongation | 10 – 20% |

| Hardness | 220 HV |

| Parameter | Value |

|---|---|

| Coefficient of Thermal Expansion | 4.8 x 10⁻⁶ /K |

| Specific Heat Capacity | 0.25 J/g·K |

| Young's Modulus | 329 GPa |

| Modulus of Elasticity | 330 GPa |

| Poisson's Ratio | 0.31 |

|

|

Physical and Chemical Properties

Molybdenum alloy strip foil brags a mix surprising physical and synthetic properties that make it ideal for different high level applications:

High Melting Point: With a melting point of 2620°C, molybdenum alloy can withstand extreme temperatures.

Excellent Thermal Conductivity: Ensures efficient heat dissipation in high-temperature environments.

High Density: Provides robustness and stability in structural applications.

Good Electrical Conductivity: Suitable for electrical and electronic components.

Corrosion Resistance: Resistant to many corrosive environments, prolonging the lifespan of the material.

|

|

Molybdenum Alloy Strip Foil Functions

- Control of the heat: Because of its high warm conductivity, molybdenum alloy strip foil is utilized in applications requiring productive intensity scattering, for example, heat sinks and warm connection point materials.

- Components of the Structure: It is suitable for structural components in the military and aerospace industries due to its high mechanical strength and density.

- Electronic Software: It is ideal for use in semiconductor components and electronic devices due to its excellent electrical conductivity.

- Coatings that Protect: Protective coatings make use of its corrosion resistance to extend the life of a variety of products.

Molybdenum Alloy Strip Foil Applications

- The Aerospace Sector: utilized in components of spacecraft and aircraft due to its capacity to withstand extreme temperatures and high strength-to-weight ratio.

- Gadgets Industry: essential in the production of electronic components like circuit boards and semiconductors. Applications in the military: utilized in the production of weaponry, armor plating, and other components related to defense.

- Modern Heaters: due to its thermal stability, utilized in the components and lining of industrial furnaces that operate at high temperatures.

- Medical Equipment: used in medical equipment that needs materials that are strong and won't rust.

|

|

Manufacturing Process and Production Flow

The production of High-Strength Molybdenum Foil at Shaanxi Peakrise Metal Co., Ltd. involves several meticulous steps to ensure the highest quality:

- Raw Material Selection: Sourcing of high-purity molybdenum ore.

- Melting: The ore is melted in vacuum arc melting furnaces to achieve the desired alloy composition.

- Rolling: The molten alloy is rolled into thin strips using state-of-the-art rolling mills.

- Annealing: The rolled strips undergo annealing to enhance their mechanical properties and ensure uniformity.

- Cutting and Finishing: The annealed strips are cut to specified dimensions and undergo finishing processes to meet customer requirements.

|

|

|

Company Introduction

Our item choice incorporates in excess of 100 unmistakable blends, with an accentuation on flight, clinical, and electronic contraptions.

We have grown a ton since we began in 2010, focusing on global exchange and extending our market reach.

Our dedication to quality and cutting-edge production facilities have earned us a reputation for greatness.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging:

- Wooden Crates: Robust and suitable for heavy and large shipments.

- Cardboard Boxes: Lightweight and ideal for smaller shipments.

- Foam Padding: Provides cushioning to prevent damage during transit.

- Waterproof and Moisture-proof Packaging: Ensures product integrity in various environmental conditions.

- Custom Packaging: Tailored solutions to meet specific customer requirements.

- International Standard Packaging: Complies with global shipping standards for safe delivery.

Logistics:

- Sea Freight: Cost-effective for large volumes and long distances.

- Air Freight: Fast and reliable for urgent deliveries.

- Land Transportation: Flexible and suitable for regional shipments.

- Multimodal Transport: Combines different modes of transportation for optimal efficiency.

- Courier Services: Ideal for small and time-sensitive packages.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Expertise: Over a decade of experience in non-ferrous metal production.

- Quality Assurance: Rigorous testing and quality control measures.

- Advanced Facilities: State-of-the-art equipment for precise manufacturing.

- Global Reach: Exporting to numerous countries with a strong customer base.

- Customer Satisfaction: High level of customer recognition and evaluation.

- Innovation: Continuous research and development to enhance product offerings.

|

|

OEM/ODM Services

To meet the specific requirements of our clients, Shaanxi Peakrise Metal Co., Ltd. provides a comprehensive selection of OEM and ODM services.

We provide services for custom processing, allowing you to modify our products to meet your specific needs.

To guarantee that your necessities are met precisely and to the most elevated conceivable norm, our gifted group will work intimately with you.

|

|

FAQs

-

What is the minimum order quantity?

The minimum order quantity is determined by the product's specifications.

For more information, contact us.

-

Do you have any illustrations?

We are able to offer evaluation samples, yes. Kindly reach out to us to examine your example needs.

-

What is the lead time for orders?

The lead time is determined by the order's specifications and size.

It usually lasts anywhere from two to six weeks.

-

Do you offer technical support?

Yes, we offer full technical support to help you with your projects and applications.

-

Accepted forms of payment include:

Payment methods include PayPal, letters of credit, and bank transfers.

Contact Us

Shaanxi Peakrise Metal Co., Ltd. is a great option for global buyers looking for the molybdenum alloy strip foil.

We are the best choice for your business because we are committed to quality, innovation, and customer fulfillment.

Contact us today at info@peakrisemetal.com to learn more about our products and services. We look forward to collaborating with you!