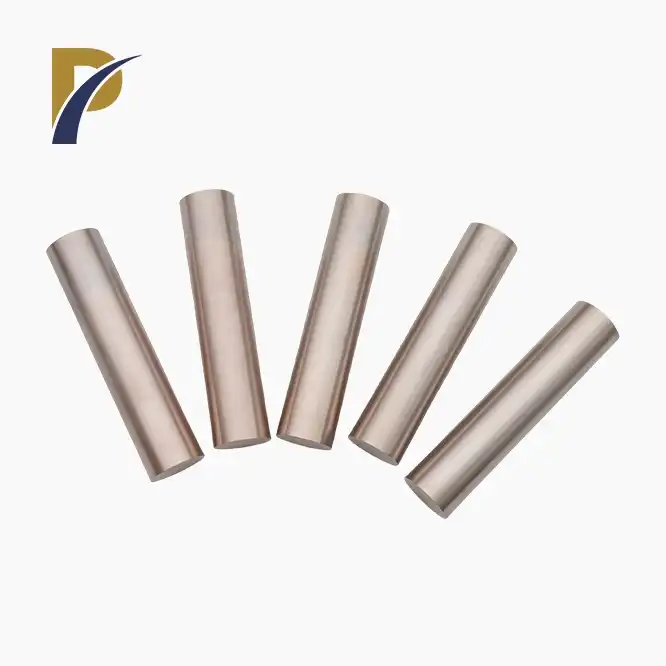

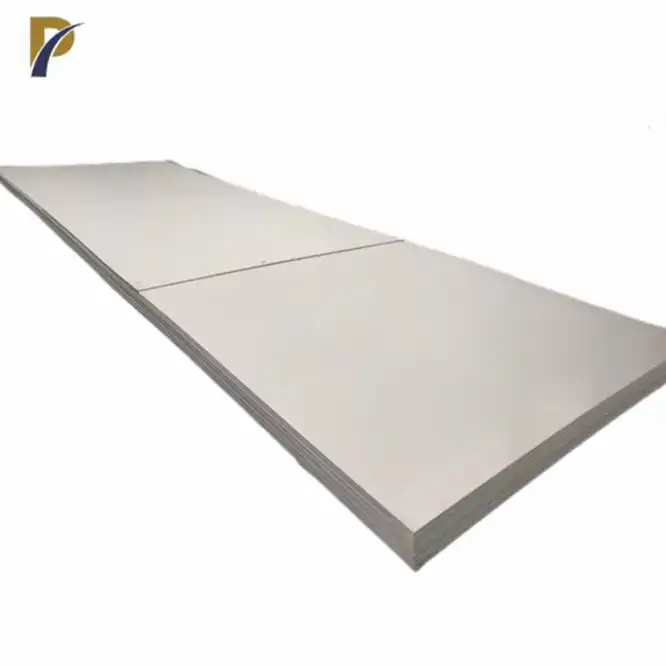

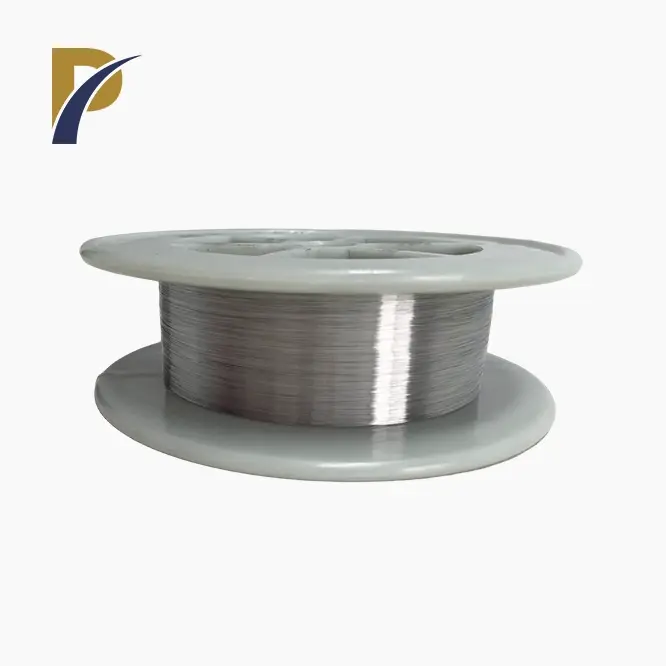

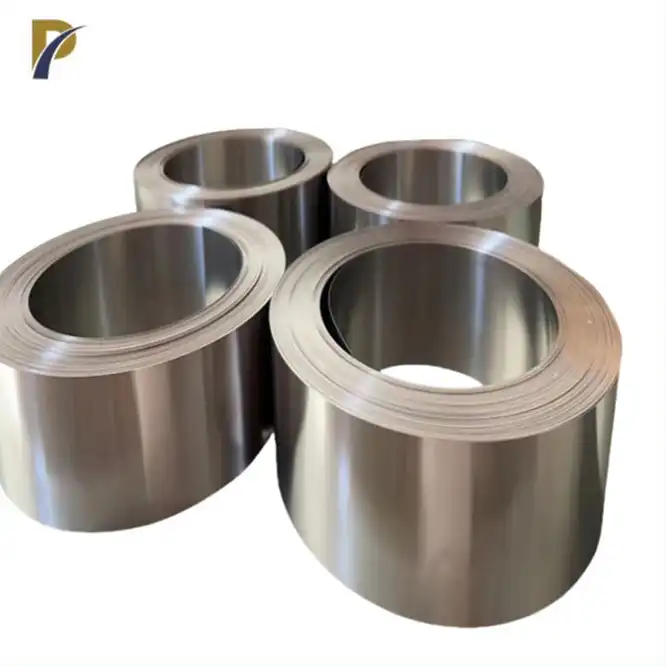

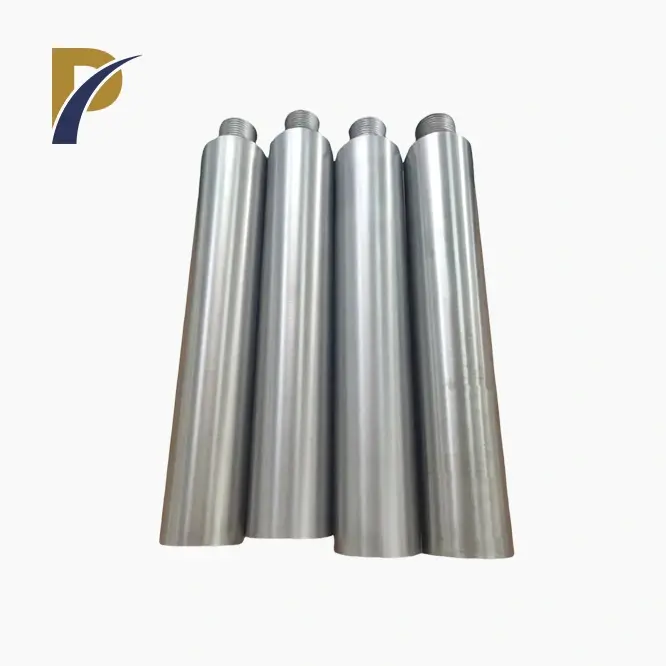

copper tungsten alloy

Surface: Polished

Resistivity: ≤3.2~6.5μΩ·m

Flexural Strength: ≥1160~≥790MPa

Impact Strength: ≥30J

Coefficient Of Thermal Expansion: 6.3-9.7×10-6/K

Density: 11.9-17.3g/cm3

Tensile Strength: ≥1000MPa

PRODUCT DESCRIPTION

Copper Tungsten Alloy Introduction

At Elite Alloys, we specialize in high-quality copper tungsten alloys. Our products blend the best properties of copper and tungsten, offering:

• High density

• Excellent thermal conductivity

• Superior electrical conductivity

• Great wear resistance

• Good machinability

We use advanced manufacturing techniques to ensure consistent quality and performance in every batch.

Product Parameters

| Property | Value |

|---|---|

| Tungsten Content (%) | 70-90 |

| Copper Content (%) | 10-30 |

| Density (g/cm³) | 15.8-18.5 |

| Electrical Conductivity (% IACS) | 30-45 |

| Thermal Conductivity (W/m·K) | 160-200 |

| Hardness (HB) | 180-260 |

| Tensile Strength (MPa) | 500-800 |

| Melting Point (°C) | 3,400 (W) |

| Coefficient of Thermal Expansion (10^-6/°C) | 6.5-8.5 |

|

|

Physical and Chemical Properties

Copper tungsten alloy exhibits a unique combination of properties:

High Density: The alloy's density ranges from 15.8 to 18.5 g/cm³, providing excellent stability and resistance to deformation.

Thermal Conductivity: With thermal conductivity between 160 and 200 W/m·K, it effectively dissipates heat.

Electrical Conductivity: The alloy retains good electrical conductivity, between 30 and 45% IACS, making it suitable for electrical applications.

Hardness: It features a hardness range of 180 to 260 HB, ensuring durability and wear resistance.

High Melting Point: The alloy has a melting point of approximately 3,400°C (depending on the tungsten content), enabling performance at high temperatures.

|

|

Copper Tungsten Alloy Functions

Its high thermal and electrical conductivity makes it ideal for use in heat sinks and electrical connections.

Wear Resistance:

The tungsten component provides excellent wear resistance, ensuring long-lasting performance in abrasive environments.

High Density:

The high density of the alloy offers stability and minimizes vibration, crucial for precision applications.

Thermal Stability: Adaptable to high temperatures and capable of withstanding harsh temperatures without degrading.Corrosion Resistance:

Resistant to corrosion and oxidation, extending the lifespan of components in challenging conditions.

Application

Our Copper Tungsten Alloy is widely used in various industries:

Electronics: Heat sinks, packaging materials, and electrodes.

Aerospace and Defense: Missile fins, aircraft counterweights, and electrical contacts.

Automotive: Electrical contacts, arc protection, and battery terminals.

Medical: X-ray shielding, medical electrodes, and imaging equipment.

Industrial Manufacturing: Electrical contacts, welding electrodes, and high-temperature components.

|

|

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is a prominent manufacturer and supplier of nonferrous metals, including alloys including nickel, titanium, zirconium, molybdenum, tantalum, and niobium.

Our diverse product offering, which includes over 100 different items, is intended to meet the diverse needs of our global customer base.

We have concentrated on exporting premium non-ferrous metal goods since 2010, building enduring connections with clients in Taiwan, South Korea, the US, Australia, Germany, Iran, and other nations.Our products are renowned for their high caliber and durability.

Lathes, milling machines, sawing machines, drilling machines, shears, grinders, straightening machines, CNC machines, and more are all part of our vast inventory of state-of-the-art manufacturing equipment.

In addition, we have laser cutters, vacuum arc melting furnaces, vacuum annealing furnaces, wire drawing machines, rolling mills, and plasma electron beam melting furnaces.It seems like this data is rather automated.This enables us to consistently deliver top-notch products and services.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Transport and Packaging

Packaging Alternatives:

Packaging in wooden crates

carton wrapping

Foam-filled containers

Packaging that is both moisture- and water-proof

Personalized packaging

Globally accepted packaging standards

Options for logistics: air freight, sea freight, land transport

Transport in several modes

expedited delivery options

|

|

|

|

|

|

|

|

|

|

|

|

|

Why Chooose Us?

High Quality: We ensure the highest purity and consistency in our alloys.

Custom Solutions: We offer custom alloy formulations to meet specific needs.

Reliable Supply: Stable inventory and timely delivery to meet your project deadlines.

Expert Support: Our team provides technical support and consultation throughout the purchasing process.

Frequently asked questions (FAQs)

What is the normal composition of copper-tungsten alloys?

Copper tungsten alloys are generally made up of 70-90% tungsten and 10-30% copper, depending on the required characteristics.

What are the primary applications of copper tungsten alloy?

Common applications include electrical contacts, heat sinks, aerospace components, industrial machinery, and radiation shielding.

How does copper tungsten alloy perform in high-temperature environments?

Copper tungsten exhibits excellent thermal stability, making it suitable for use in extreme temperatures.

Can you provide custom sizes and shapes for copper tungsten alloy?

Yes, we offer OEM/ODM services and can customize products to meet specific client requirements.

What are the delivery methods for foreign orders?

We offer various logistics options, including sea freight, air freight, land transport, multimodal transport, and express delivery services.

Contact us

For premium copper tungsten alloys and other non-ferrous metal goods, we cordially encourage customers from across the world to collaborate with Shaanxi Peakrise Metal Co., Ltd. You will always get the greatest products and services from us since we are dedicated to quality and client satisfaction. Reach us at info@peakrisemetal.com for ordering or further information. We are eager to collaborate with you and provide your requirements with our superior goods and services.