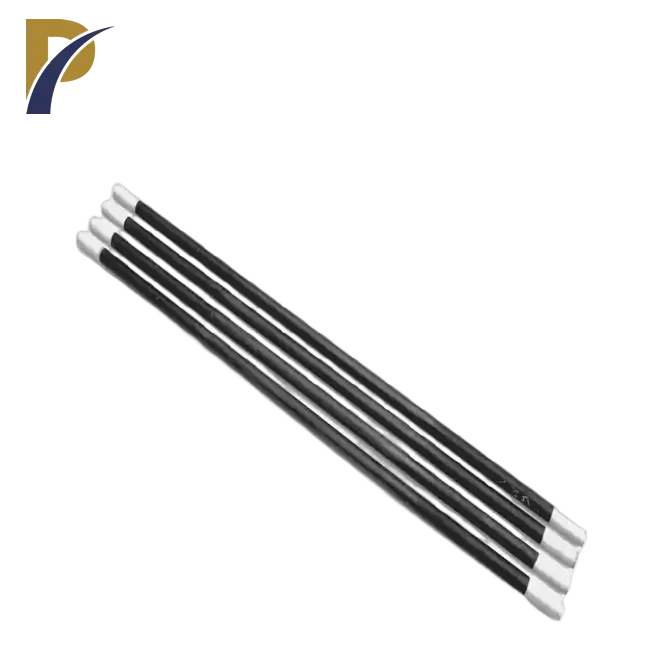

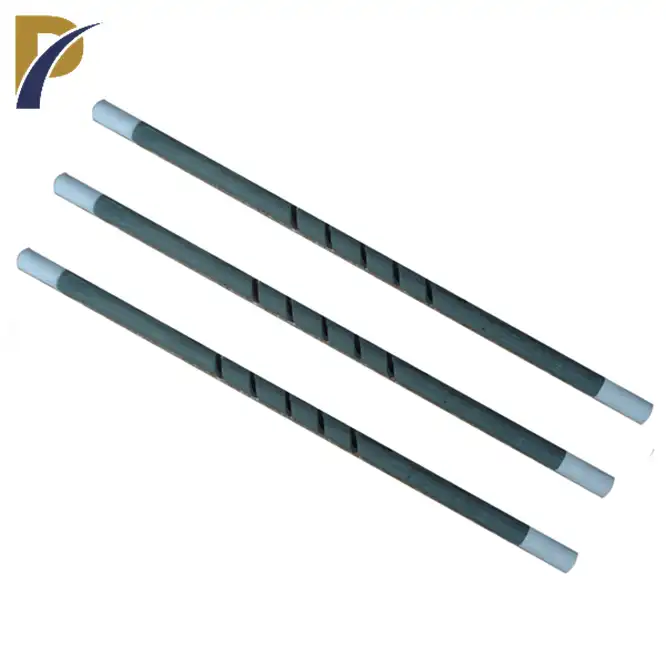

sic heating elements

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

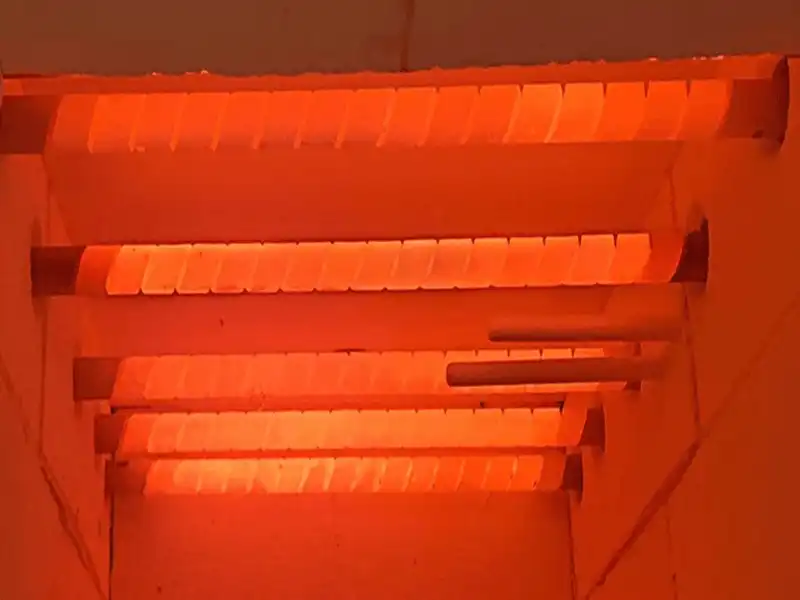

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

SiC Heating Elements Introduction

The sic heating elements are widely recognized in the industry for their high-temperature capabilities, exceptional thermal conductivity, and long lifespan. As a leading supplier, Shaanxi Peakrise Metal Co., Ltd. specializes in providing top-quality SiC heating elements that cater to a broad range of industrial applications, from metallurgy and ceramics to glass production and laboratory research.

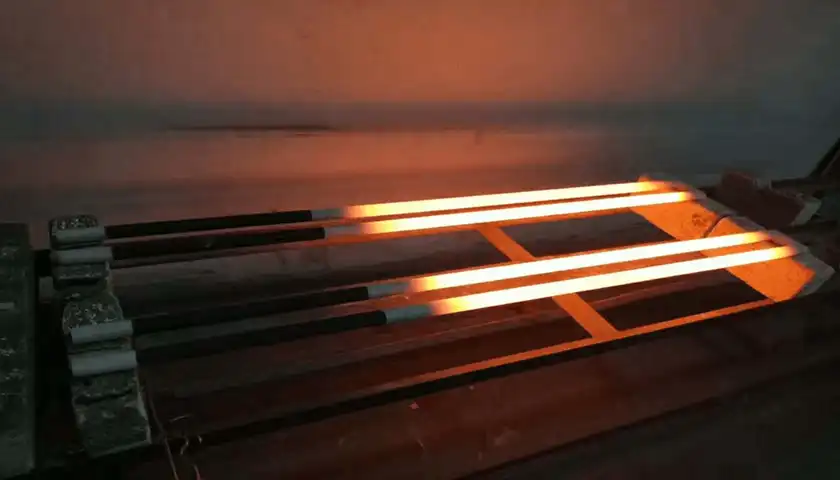

Our products are manufactured with precision and undergo stringent quality control to ensure optimal performance and durability. Designed to operate efficiently at temperatures up to 1600°C (2912°F), these products are perfect for high-temperature processes, delivering consistent and reliable heating. Our expertise in non-ferrous and refractory metal production allows us to create sic heating elements that meet the highest industry standards.

Product Specifications

| Parameter | Value |

|---|---|

| Maximum Temperature | 1600°C |

| Resistance Range | 0.1Ω - 100Ω |

| Density | 3.1 g/cm³ |

| Electrical Conductivity | 0.01 S/cm |

| Length | 100mm - 1500mm |

| Diameter | 10mm - 50mm |

| Operating Voltage | 110V - 480V |

| Type | Standard Sizes |

|---|---|

| Rod Elements | 300mm, 500mm, 1000mm |

| Dumbbell Elements | 300mm, 500mm, 1000mm |

| U-Shaped Elements | 400mm, 600mm, 1200mm |

| Temperature Zone | Value |

|---|---|

| Cold End Length | 50mm |

| Hot Zone Length | 200mm - 1000mm |

| Resistance Tolerance | ±10% |

|

|

Physical and Chemical Properties

The sic heating elements are composed of high-purity silicon carbide, offering excellent chemical stability, thermal conductivity, and mechanical strength. The products exhibit high resistance to oxidation and corrosion, making them suitable for use in aggressive environments. Additionally, the products have low thermal expansion, ensuring dimensional stability even at high temperatures.

|

|

Product Features

- High Temperature Resistance: Capable of operating at temperatures up to 1600°C, ideal for high-temperature industrial processes.

- Durable and Long-Lasting: Made from high-purity silicon carbide, these products are designed for extended service life.

- Excellent Thermal Conductivity: Provides uniform and efficient heating, reducing energy consumption.

- High Mechanical Strength: Resistant to thermal shock and mechanical stress, ensuring reliability.

- Corrosion and Oxidation Resistance: Suitable for use in harsh environments, maintaining performance over time.

Sic Heating Elements Applications

- Metallurgy: sic heating elements is used in furnaces for melting and heat treatment of metals, providing precise temperature control.

- Ceramics: Essential for firing and sintering ceramics, ensuring uniform heating and product quality.

- Glass Production: Utilized in glass melting furnaces, enhancing production efficiency and glass quality.

- Laboratory Research: Ideal for high-temperature experiments and materials testing.

- Semiconductor Manufacturing: Employed in processes requiring stable and high-temperature environments.

|

|

Manufacturing Process

Our products are produced through a meticulous manufacturing process that includes:

- Raw Material Selection: Using high-purity silicon carbide to ensure product quality.

- Mixing and Forming: Combining raw materials and forming them into the desired shapes.

- Sintering: Heating the formed elements in a high-temperature furnace to achieve the desired properties.

- Machining: Precision machining to achieve exact dimensions and tolerances.

- Quality Testing: Rigorous testing for electrical and mechanical properties to ensure reliability and performance.

|

|

|

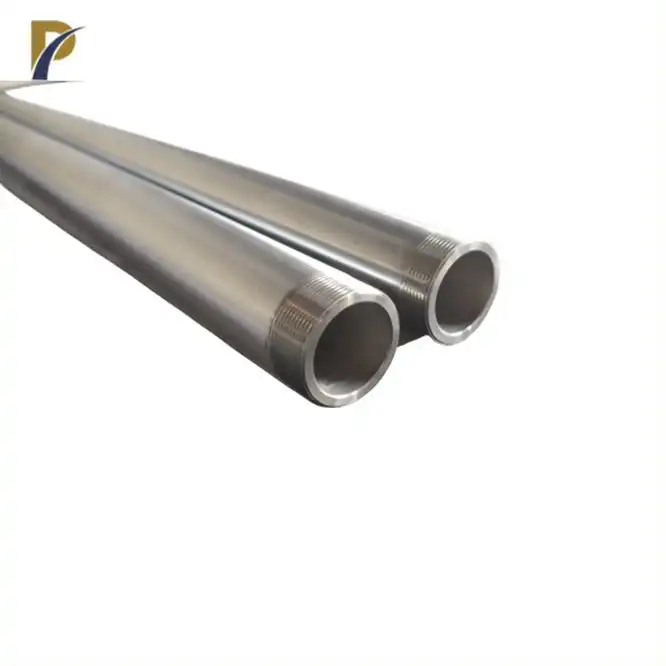

About Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts a state-of-the-art manufacturing facility equipped with advanced production equipment, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, and laser cutters. Our factory adheres to strict quality control protocols, ensuring that every product meets international standards.

Our team of experienced professionals is dedicated to continuous improvement and innovation, allowing us to provide high-quality products and services to our global customers. With a focus on research and development, we are at the forefront of the non-ferrous and refractory metal industry.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging:

- Wooden Crates

- Carton Boxes

- Foam Padding

- Waterproof and Moisture-Proof Packaging

- Customized Packaging

- International Standard Packaging

Logistics:

- Sea Freight

- Air Freight

- Land Transport

- Multimodal Transport

- Express Delivery Services

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Extensive Experience: Over a decade of expertise in non-ferrous and refractory metal production.

- High-Quality Products: Commitment to delivering products that meet the highest industry standards.

- Comprehensive Services: From manufacturing to material research and product testing.

- Global Reach: Exporting to various countries with a strong reputation among international customers.

- State-of-the-Art Equipment: Equipped with advanced production and testing facilities.

- Customer-Centric Approach: Focused on providing exceptional customer service and support.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers customizable OEM/ODM services to meet your specific needs. Whether you require unique dimensions, special material properties, or tailored packaging, we can accommodate your requests. Our team works closely with clients to deliver solutions that align with their requirements, ensuring satisfaction and long-term partnerships.

|

|

Frequently Asked Questions (FAQ)

-

What is the maximum operating temperature of your SiC heating elements?

- Our products can operate at temperatures up to 1600°C (2912°F).

-

Can you provide customized dimensions for SiC heating elements?

- Yes, we offer custom sizes and shapes to meet your specific requirements.

-

How do you ensure the quality of your SiC heating elements?

- Our products undergo rigorous quality testing, including electrical and mechanical property assessments.

-

What is the typical lifespan of an SiC heating element?

- With proper use, our products have a long lifespan, often exceeding several thousand hours of operation.

-

Do you offer international shipping?

- Yes, we provide global shipping options, including sea, air, and land transport.

Contact us

Interested in high-quality SiC heating elements for your industrial needs? Shaanxi Peakrise Metal Co., Ltd. is your reliable partner. Reach out to us at info@peakrisemetal.com to discuss your requirements and receive a quote. Our team is ready to assist you with top-notch products and exceptional service. Let's work together to achieve your heating solutions!