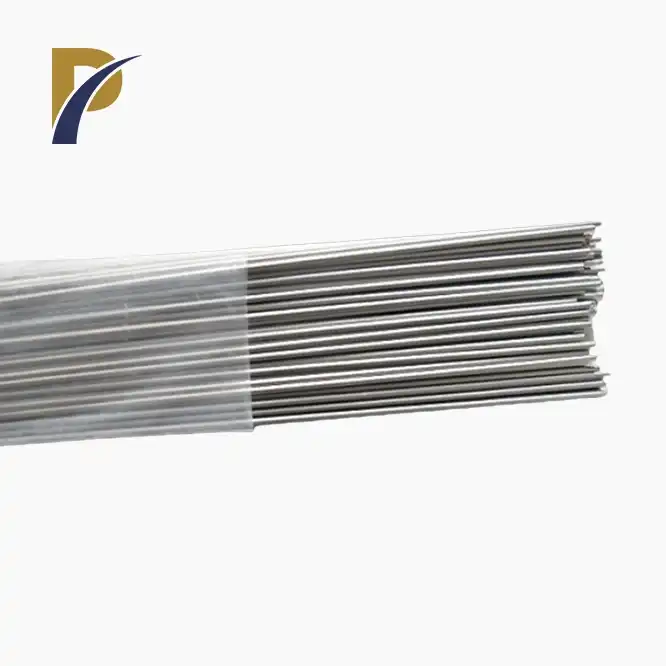

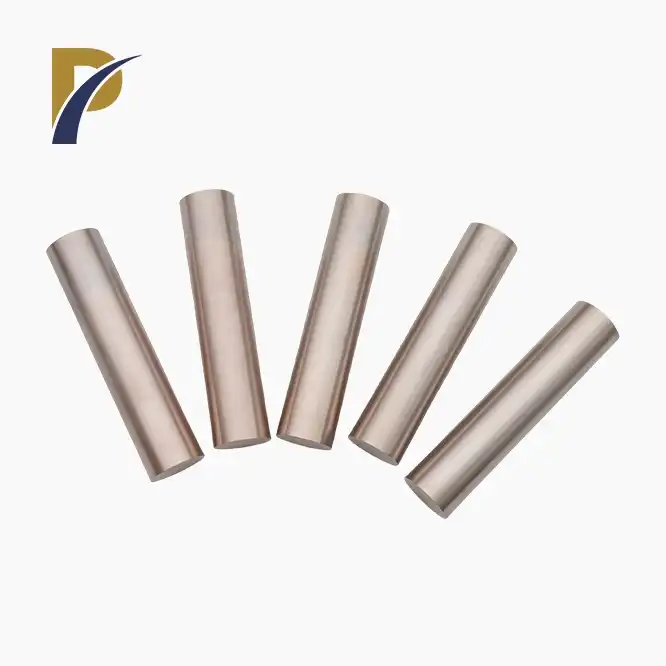

titanium tig welding rod

Material: Titanium & Titanium Alloy

Grade: GR1,GR2,GR5,GR7,GR9,GR12

Chinese grades: TA1, TA2, TA3, TA7, TA9, TA10, TC4, TC4ELI, TC6, TC9, TC10, TC11

Diameter: φ4~200mm

Length: ≤6000mm

Surface: Polished

Density: 4.51g/cm3

Standard: ASTM B348, ASTM F136, ASTM F67, AMS4928 Application: Aerospace industry,Medical devices,Chemical Industry,Automotive industry.

PRODUCT DESCRIPTION

Titanium Tig Welding Rod Introduction

At Peakrise, we specialize in producing high-quality titanium TIG welding rod that meet the stringent requirements of various industries, including aerospace, medical, chemical, and energy. Our rods are designed to provide exceptional strength, corrosion resistance, and weldability.

Product Parameters

| Property | Value |

|---|---|

| Diameter | 1.6 mm, 2.0 mm, 2.4 mm |

| Length | 914 mm (36 inches) |

| Composition | Titanium alloy |

| Tensile Strength | 800 MPa |

| Yield Strength | 700 MPa |

| Elongation | 15% |

| Melting Point | 1670°C (3038°F) |

| Density | 4.5 g/cm³ |

| Surface | Pickled, Polished |

| Certification | ISO 9001:2015 |

|

Physical and Chemical Properties

Due to their exceptional qualities, Titanium Jewelry Wire stand out in the welding industry. Their consumption obstruction is a champion element, safeguarding the welds from the harming impacts of destructive substances, which is vital in conditions presented to cruel synthetics or marine circumstances. These rods' high strength makes sure that the welds they make are strong and dependable, able to withstand a lot of stress and strain without breaking.

The sublime weldability of titanium TIG bars makes them a #1 among welders, as they can be handily controlled to accomplish a perfect and exact weld. This trademark is especially significant in applications where accuracy and quality are principal, like in the aviation, car, and clinical enterprises. Additionally, their low density makes them more accessible for use in a variety of welding projects due to their ease of handling.

Additionally, these titanium rods' inability to deform at high temperatures is a significant advantage. This property guarantees that the welds they make can get through outrageous warm circumstances, keeping up with their respectability and execution in applications like motor parts or high-temperature modern gear. Titanium TIG welding rod are highly sought after for demanding welding applications because of the combination of these properties.

|

|

Titanium Tig Welding Rod Features

- Superb Welding Performance: Ensures stable arc, minimal spatter.

- High Strength: Provides durable welds in challenging conditions.

- Corrosion Resistance: titanium tig welding rod is ideal for use in corrosive environments.

- Uniform Composition: Consistent chemical properties ensure reliable welding results.

Product Applications

- Aerospace Industry: Critical for aircraft and spacecraft construction.

- Marine Engineering: Used in shipbuilding due to seawater corrosion resistance.

- Chemical Processing: Resistant to chemical corrosion in industrial settings.

- Medical Equipment: Biocompatible material for medical device manufacturing.

- Automotive Sector: Welding of automotive components for structural integrity.

|

|

Production Process

Our Titanium Jewelry Wires are manufactured using advanced processes including vacuum arc melting and precision rolling. Each rod undergoes rigorous quality control to meet international standards.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates with state-of-the-art equipment including vacuum annealing furnaces, plasma welding rooms, and CNC machines. We ensure precise manufacturing and timely delivery.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

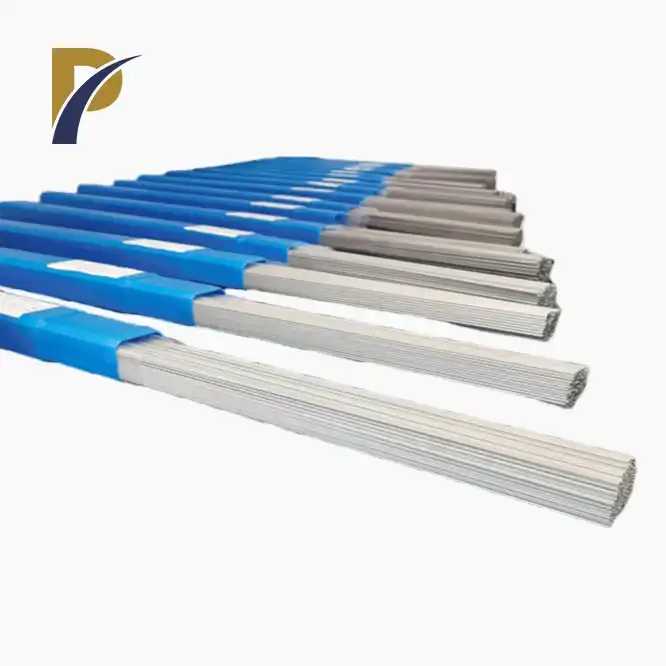

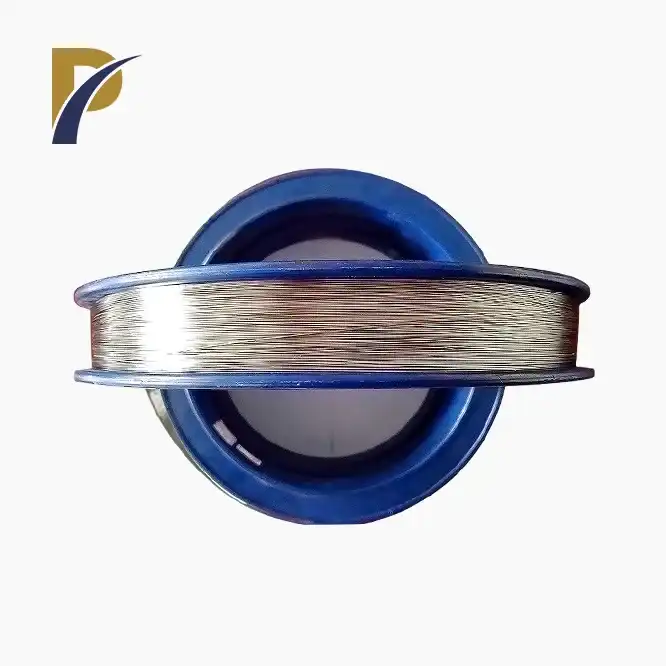

Packaging

- Wooden Crates: For secure transportation of bulk orders.

- Cardboard Boxes: Ideal for smaller quantities.

- Customized Packing: Tailored to client specifications for added protection.

- Moisture Barrier Packaging: Ensures product integrity in humid climates.

- Compliance: All packaging meets international shipping standards.

Logistics

Shipping Options: Sea freight, air freight, land transportation, and express delivery services ensure flexible and timely shipment worldwide.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Extensive Experience: Over a decade in non-ferrous metal production.

- Global Reach: Trusted by clients in Taiwan, Ukraine, USA, and beyond.

- Quality Assurance: ISO-certified processes ensure top-tier products.

- Customization: OEM/ODM services available to meet unique requirements.

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services, accommodating custom specifications to meet diverse client needs.

|

|

FAQ

-

What are the typical applications of titanium TIG welding rod?

- Answer: They are used in aerospace, marine, and medical industries due to their corrosion resistance and high strength.

-

Are your products ISO certified?

- Answer: Yes, we adhere to ISO 9001:2015 standards for quality management.

-

What sizes are available?

- Answer: We offer diameters ranging from 1.6 mm to 2.4 mm and lengths of 914 mm.

-

How do you ensure product quality?

- Answer: We conduct rigorous quality checks throughout the manufacturing process.

-

Can you handle bulk orders?

- Answer: Yes, we have the capacity to fulfill large-scale orders with prompt delivery.

Contact us

Contact us today at info@peakrisemetal.com to discuss your High-Strength titanium tig welding rod requirements. Partner with Shaanxi Peakrise Metal Co., Ltd. for superior quality and reliable service.